First of all,

welded pipe is different from seamless pipe and is easy to understand.

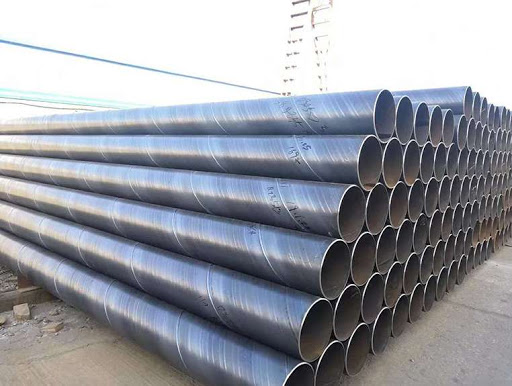

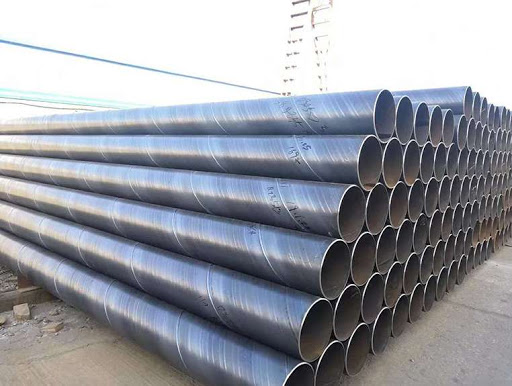

Among the welded pipes, the one with a large diameter will be made into a spiral welded pipe, which is made of steel strip wound, and the weld is also spiral.

Among the welded pipes, the smaller diameter can be completed by a combined pipe making unit (including welding and cutting) using strip steel, and the weld is a straight seam.

Steel pipes are divided into seamless and welded pipes.

Welded pipes are divided into straight seams and spirals.

Straight seam welded pipes are divided into ERW (high frequency resistance welding) and LSAW (longitudinal submerged arc welding).

Spiral pipe welding process is also submerged arc welding (SSAW for short). The difference between LSAW and LSAW is the weld form. The difference from ERW is the difference in welding process. Submerged arc welding (SAW) requires the addition of media (welding wire, flux), and ERW does not Need, ERW is melted by heating at intermediate frequency.

The steel pipe is first divided into: seamless pipe and welded pipe (basically it can be separated from the appearance)

The welded pipe is divided into: straight welded pipe and spiral welded pipe (can be distinguished from the appearance)

Longitudinal welded pipes are roughly divided into: ERW, JCOE, UOE, etc.

Spiral welded pipe: SSAW

Straight seam welded pipes are restricted by the plate width during production, while spiral welded pipes are relatively limited by the plate width.