Common steel grades for oilfield API-5CT casing pipes include J55, K55, N80-1, N80Q, and P110. These casing pipes are primarily used in oil well drilling.

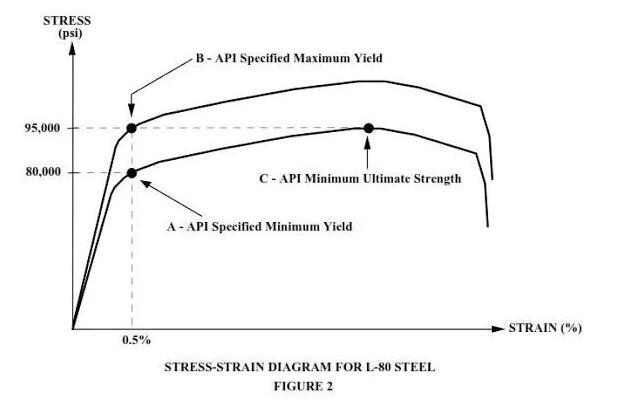

To understand API casing pipe grades, it is crucial to grasp the concepts of minimum yield stress, maximum yield stress, and minimum ultimate strength. Let's use two popular grades, L-80 and N-80, to explain these terms.

Steel Casing Pipe Grades:

The grade of a steel casing pipe is indicated by a letter followed by the minimum yield stress of the steel in psi. For example, API grade P-110 has a minimum yield stress of 110,000 psi. API grade L-80 has a minimum yield stress of 80,000 psi, which means it can withstand a stress of 80,000 psi with an elongation of 0.5%.

The letter in the grade, such as 'L' in L-80, serves as a distinguishing prefix to avoid confusion between different steel grades. This letter, combined with the number, indicates parameters such as maximum yield strength and minimum ultimate strength.

Example Grades:

L-80:

Minimum Yield Stress: 80,000 psi (point “a”)

Maximum Yield Strength: 95,000 psi (point “b”), which is 15,000 psi higher than the minimum yield stress.

Minimum Ultimate Strength: 95,000 psi (point “c”)

Hardness Specification: 23 HRC

N-80:

Minimum Yield Stress: 80,000 psi (point “a”)

Maximum Yield Strength: 110,000 psi (point “b”), which is 30,000 psi higher than the minimum yield stress and twice the tolerance of L-80.

Minimum Ultimate Strength: 100,000 psi (point “c”)

Hardness Specification: None

Key Differences:

Tolerance and Hardness:

L-80 has a tighter tolerance on yield strength and includes a hardness specification, making it more suitable for H2S service than N-80.

N-80 has a broader tolerance and lacks a hardness specification, making it less suitable for H2S service compared to L-80.

Understanding these parameters helps in selecting the appropriate casing pipe grade for specific applications in oil well drilling, ensuring safety and performance requirements are met.