Introduction

Introduction

Maxumum working temperature :270 F (130 C)

Base tube material: stainless steel, carbon steel, copper alloy,alloy steel (No theoretical limit)

ASME SA213/ASTM A213 TP304/304L TP316/TP316L TP321 TP310S TP317,

ASME SA106/ASTM A106 Gr B Gr C,ASME SA179/ASTM A179,ASME SA192/ASTMA192

ASTM B111 C70600 C44300 C68700 C71500...

Fin material: Aluminium,copper. Stainless steel L Type fins tube, carbon steel L Type fins tube copper L Type fins tube

Cu-Ni L fins tube,Aluminium brass L fins tube Copper-nickel L Type fins tube Duplex L Type fins tube super duplex L type fins tube Air cooler fins tube, air preheater fins tube.

Extruded fins tube Serrated fin tubes L Type fins tube G Type fins tube LL Type fins tube H Type fins tube KL Type fins tube HFW fin tube laser welded fin tube.

Advantages of finned tube

Provide 8 to 12 times the heat transfer area of bare tubes.

More efficient than bare tubes.

Provide smaller exchangers due to increased Heat Transfer area.

Often provide a more economical selection.

Fins can be "Cut & Twist" to increase shell side fluid turbulence and improve heat transfer.

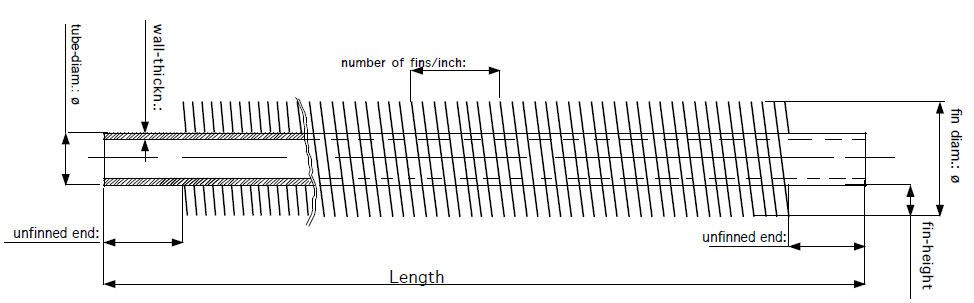

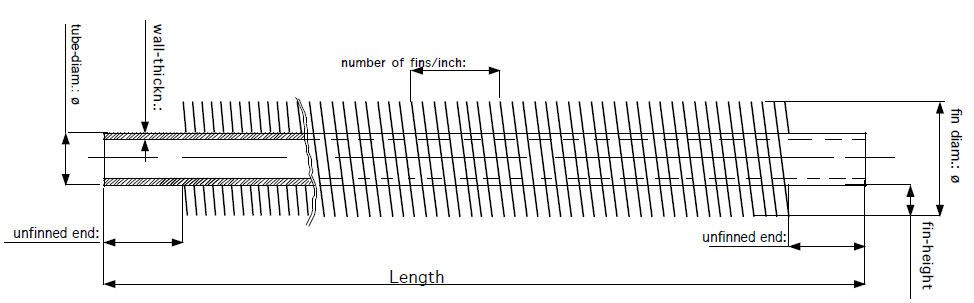

Base pipe O.D:15.88-165mm

Fin height:6-50mm

Fin thickness:0.3-0.5mm

Fin pitch: as customer's request.

End:Plain Ends, Beveled Ends

No fin area on both side:As Customer's request.

Specification

Specification

|

Type

|

Description

|

Base tube

O.D. (mm)

|

Fin specification (mm)

|

|

Fin pitch

|

Fin height

|

Fin thick

|

|

Embedded

|

G-type fin tube

|

16-63

|

2.1-5

|

<17

|

~0.4

|

|

Extruded

|

Single metal combined metal

|

8-51

|

1.6-10

|

<17

|

0.2-0.4

|

|

Low fin tube t-type fin tube

|

10-38

|

0.6-2

|

<1.6

|

~0.3

|

|

Bamboo tube corrugated tube

|

16-51

|

8-30

|

<2.5

|

/

|

|

Wound

|

l/kl/ll type fin tube

|

16-63

|

2.1-5

|

<17

|

~0.4

|

|

String

|

String fin tube

|

25-38

|

2.1-3.5

|

<20

|

0.2-0.5

|

|

U-type

|

U-type tube

|

16-38

|

/

|

/

|

/

|

|

Welding

|

HF-welding fin tube

|

16-219

|

3-25

|

5-30

|

0.8-3

|

|

H/HH type fin tube

|

25-63

|

8-30

|

<200

|

1.5-3.5

|

|

Studed fin tube

|

25-219

|

8-30

|

5-35

|

φ5-20

|

|

Fin material

|

N° fins per meter

|

Strip thickness

|

Production capacity

|

|

All type of material

|

From 50 to 500

|

From 0,4mm. to 0,5mm.

|

More than 500 meters per day

|

|

Tube material

|

Tube thickness

|

O.D. tube

|

Lenght available

|

|

All type of material

|

1,00mm. minimum

|

From 10,00mm. to 200,00mm.

|

All lenghts up to 8 Meters

|

|

Base Tube O.D

(mm)

|

Base Tube Thickness (mm)

|

Fin Height (mm)

|

Fin Thickness(mm)

|

Fin NO.(Pc)

|

|

25.4 mm ~152.4 mm

|

1.0 mm ~4.0 mm

|

5.0 mm ~16.0 mm

|

0.89 mm ~1.5 mm

|

2 ~ 36

|

|

Base Tube Material

|

Fin Material

|

Tube Length (Mtr)

|

|

|

|

Carbon Steel ,Alloy Steel ,Stainless Steel

|

Carbon Steel ,Alloy Steel ,Stainless Steel

|

≤ 15Mtrs

|

|

|

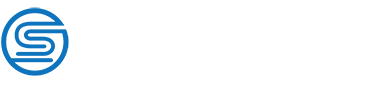

Applied Fin Tube

Applied Fin Tube

Applied Fin Tube is made with strip wrapped under tension around the base of the tube. Fins are welded to the base tube at the strip ends.

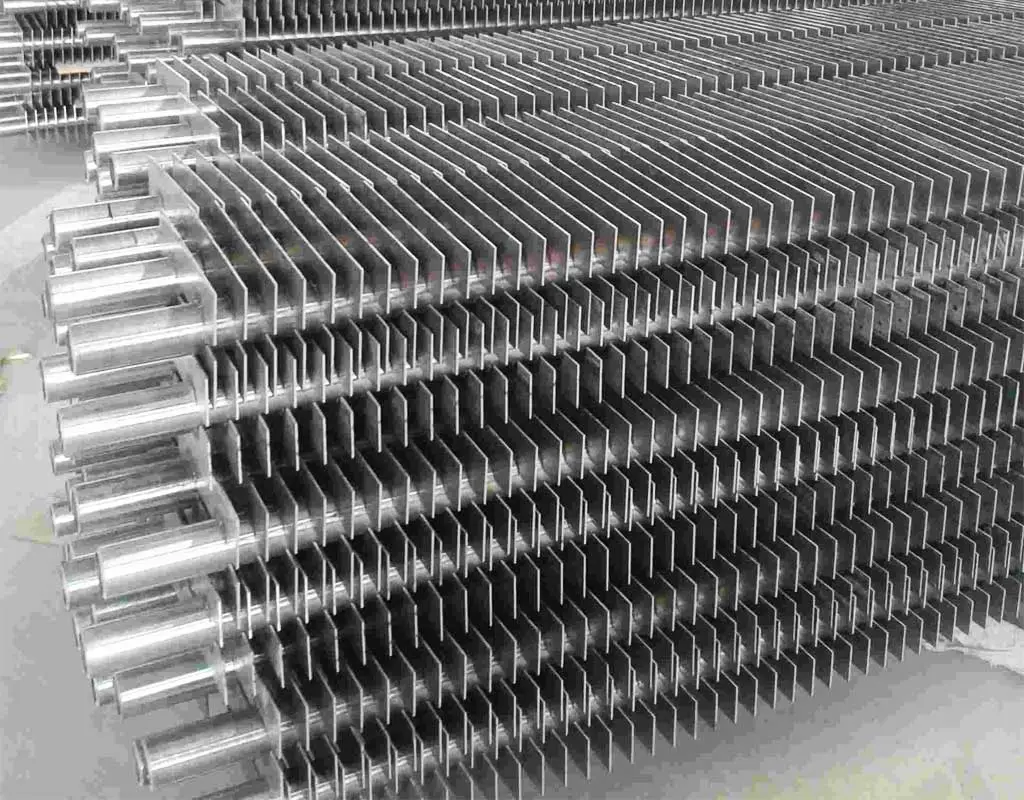

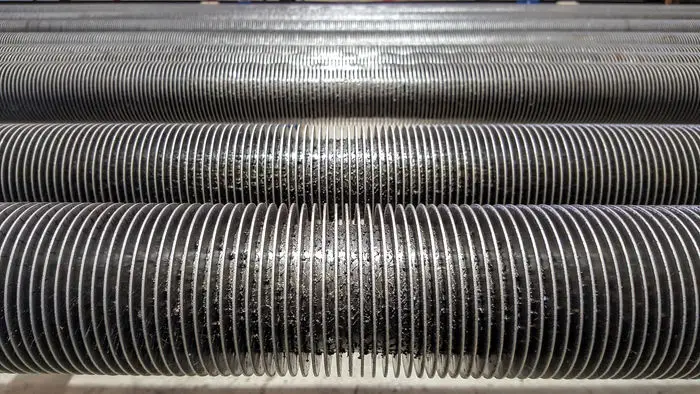

According to the wing shape and structure, finned tube can be divided into the following categories:

-

Square finned tube

-

Spiral finned tube

-

Longitudinal Finned Tube

-

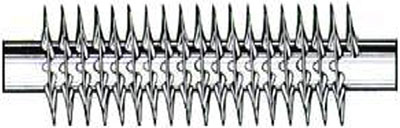

Helical Serrated Finned Tubes

-

Inner finned tube

Carbon steel fins are available on carbon, stainless steel, or copper tube. Please call for a specific size if not listed

Packing

Packing

In bundles, plywood cases, wooden cases with water-proof package, etc.

Carbon steel fins are available on carbon, stainless steel, or copper tube. Please call for a specific size if not listed

finned steel tube,finned tube,spiral finned tube,stainless steel finned tube

Manufacture Process

Manufacture Process

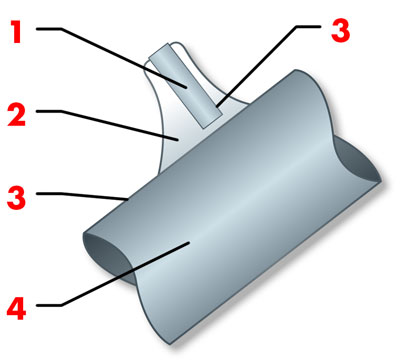

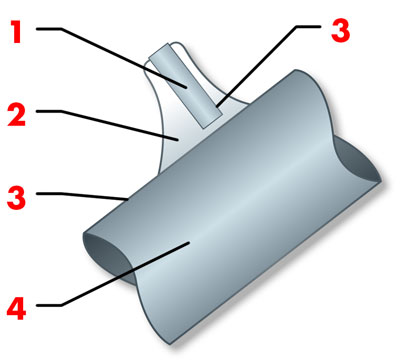

1. Heat sink

2. AL-FUSE™ adhesive fillet

3. Interface

4. Tube

Cain Industry's patented bonding process metallurgically connects the stainless steel heat sink to the aluminum tube to achieve the highest heat transfer efficiency.

Even with 100 times magnification, no voids were found in the metallurgical bonding. This is your guarantee of maximum heat transfer efficiency, and is the technical advantage of other types of finned tubes.