Ceramic lined elbows

Codo revestido de cerámica fabricado con materias primas de calidad superior. El codo revestido de cerámica se utiliza para conectar tuberías de diferentes diámetros y encuentra amplias aplicaciones en diversos productos químicos, industrias de la construcción, constructores de papel, cemento y barcos.

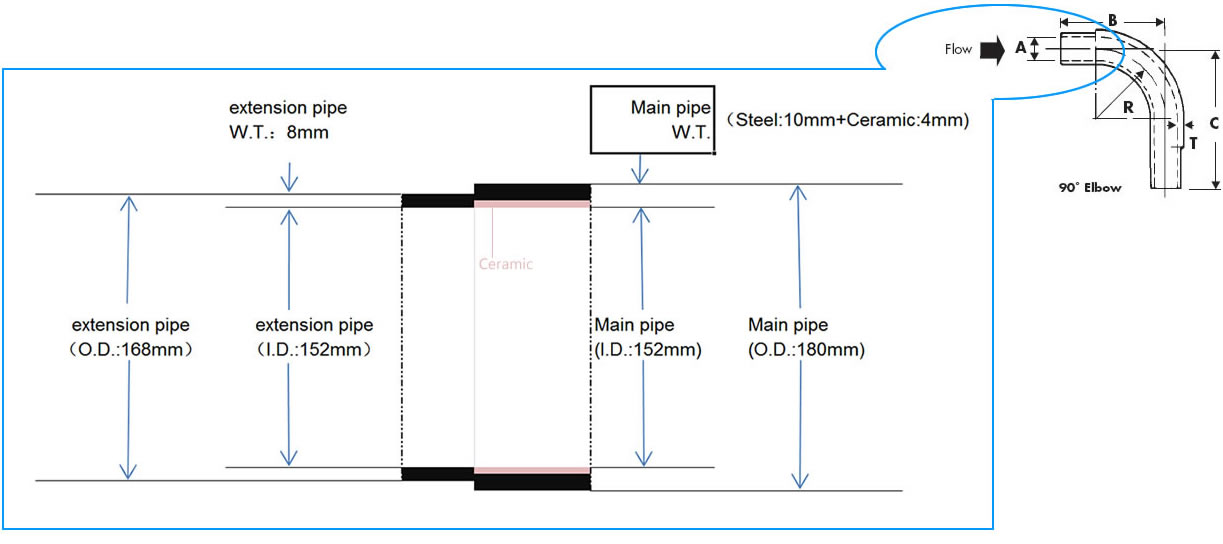

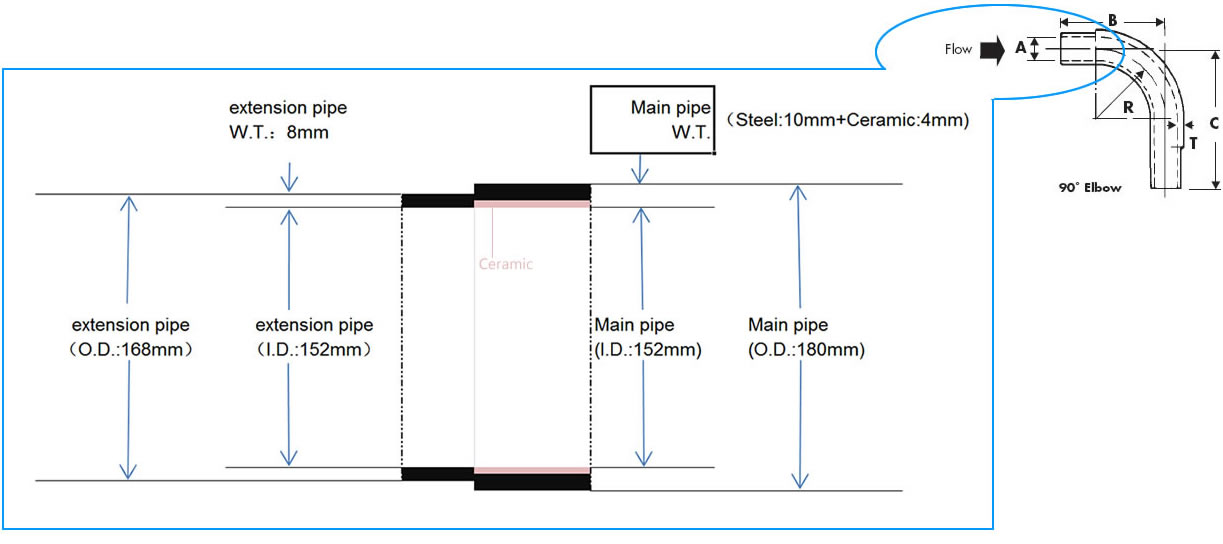

Tubos de extensión con codos revestidos de cerámica

Ceramic lined elbows Export to Tainland

Reduce considerablemente la degradación del material transportado y evita la formación de cabello de ángel a través de su cámara de deflexión patentada.

Codo Size6 ", revestimiento de cerámica.

Codo Material: acero al carbono

Material revestido de cerámica: 2Al + Fe203 = Al203 + 2Fe + 836KJ3Fe304 + 8Al203 + 9Fe + 3265KJ

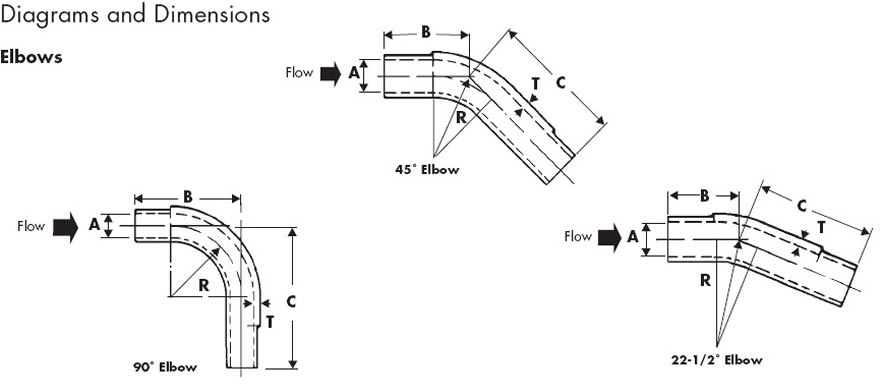

Size: 6", 22.5 Degree."R" is 18 inch

- 22.5 o Ceramic-Lined Elbow

45o Ceramic-Lined Elbow

Size: 6", 45 Degree."R" is 18 inch

90o Ceramic-Lined Elbow

Size: 6", 90 Degree."R" is 18 inch

Backpack wear-resistant ceramic lined elbow

Backpack wear-resistant ceramic lined elbow are used for connecting pipes of different diameters and find wide applications in various chemicals, construction industries, paper, cement & ship builders.

Ceramic lined elbow for Pneumatic Conveying

Tubes and bends in pneumatic conveying lines are suffering more or less abrasion. DMH United Steel's ceramic lined pipes resists abrasion and avoids product attrition.It reduces considerabley degradation of conveyed material and avoids formation of angel hair through its patented deflection chamber.The compact design reduces cost of pipe support and installation. It is automatically self-purging with little pressure drop.

Ceramic Lined Elbows and Bends could be also applied in the parts of concrete pump owing to their advantages especially the low weight which helps to avoid the jam during the transport of concrete.

Features of Alumina Ceramic lined elbow:

Alumina is a cost effective and widely used material in the family of engineered ceramics. Alumina ceramics have been developed and optimized for maximum wear resistance and corrosion resistance.

A high density, diamond like hardness,fine grain structure and superior mechanical strength are the unique properties that make it the material of choice for a wide range of demanding applications.Ceramic has uses similar to Cast Basalt but it has greater resistance to wear in high velocity applications and impact resistance in extreme dynamic systems .

Specifications & size range of ceramic lined pipe

La resistencia del aro es la resistencia contra la presión radial. La resistencia del tubo compuesto de acero con revestimiento de cerámica es de 300 a 500 MPa.

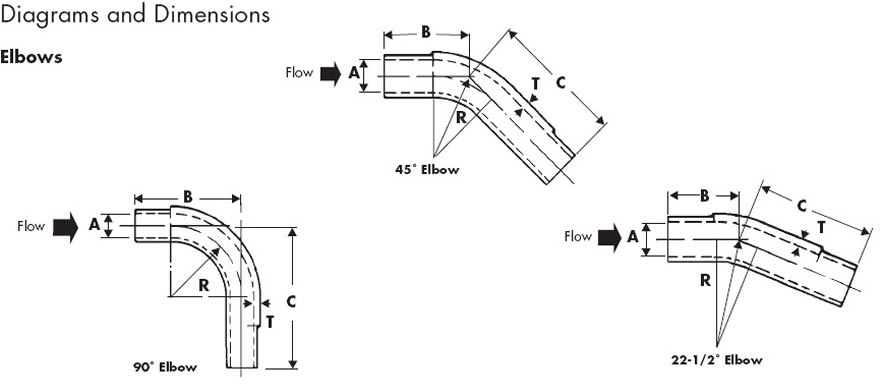

Tamaño de los codos compuestos revestidos de cerámica 22.5 grados

Tamaño de los codos compuestos revestidos de cerámica 45 grados

Tamaño de los codos compuestos forrados de cerámica 90 grados

Tamaño del tubo compuesto de acero revestido de cerámica (CLSP)

Tamaño de la camiseta compuesta forrada de cerámica

Wear-resisting comparative table of ceramic lining pipe

|

Sand injection test

|

30% Transfer test of sludge with SiO2

|

|

Material

|

Volume diminution

(cm3)

|

Material

|

Volume diminution

(cm3)

|

Ceamic lining

Steel pipe

|

0.0022

|

Ceamic lining

Steel pipe

|

3

|

Ceramic pipe

Al2O397%

|

0.0025

|

S45C

|

25

|

Main Properties of Ceramic

|

Item

|

Index

|

|

Content of Alumina

|

≥95%

|

|

Density

|

≥3.5 g/cm3

|

|

Rockwell Hardness

|

≥80 HRA

|

|

Impact Strength

|

≥850 Mpa

|

|

Bending Strength

|

≥290MPa

|

|

Breaking Temper

|

≥4.8MPa·m1/2

|

|

Coefficient of Linear Thermal Expansion

|

20W/m.K

|

Abrasion

Ceramic layer Ceramic Lined Reducer Pipe with flange reducer Al2O3 content greater than 95% , micro-hardness HV1000-1500, which has a high abrasion resistance, wear resistance than ten times higher than carbon steel after quenching , superior tungsten carbide drill.

Application range

1, coal pulverizing system of power plant pipeline, including, powder transmission pipeline, thick powder separator pipeline, coal drop pipe, combustion system of a wind pipe, a secondary air pipe, three pipeline and burner pipelines, in addition to ash slagging system the discharge pipe, powder pipe, dry ash conveying pipe;

2, iron and steel plant raw material conveying pipeline, collecting pipe, dust pipe, ash pipe, ash pipe, mixing pipe, grinding export pipeline, coal pipeline, coal pipeline, separator pipe, burner radius pipe, etc.;

3, cement plant selection machine outlet pipe, choose machine inlet pipe, pipe dust pipe, vertical mill outlet pipe, circulating air duct, high temperature air blower, lower material pipe, etc.;

4, petroleum, chemical, mining, coal, coal washing plant, smelting, paper, aluminum, building materials, powder engineering, food machinery and other processing and conveying material pipe.

Corrosion

Ceramic materials are neutral , chemically stable , has excellent corrosion resistance and acid resistance , resistant to various inorganic acids, organic acids , organic solvents , and its degree of corrosion of stainless steel is more than ten times.

Temperature

Temperature above 2000celsius degree, long-term work in the range of -50 -900 celsius degree.

Easy welding

Ceramic adjustable tube can be welded , flanged , flexible connectors and other fast way links , very easy to install.

Clean and easy maintenance

Smooth wall, can prevent scaling , fouling, self-cleaning function. Tightness.

Remarks:

1, power plant pipe pulverizing system, including powder pipeline, thick powder separation pipe, coal dropper, wind pipe combustion system, two wind pipe, three pipe and burner pipe, except ash system discharge pipe, powder pipe, dry ash conveying pipe;

2, raw material pipeline of iron and steel plant, collecting pipe, dust collection pipe, ash pipe, ash pipe, mixing pipe, grinding outlet pipe, coal pipe, coal pipe, separation pipe, burner radius pipe, etc.

3, the cement plant chooses machine outlet pipe, choose machine inlet pipe, pipe dust removal pipe, vertical mill outlet pipe, circulating air duct, high temperature blower, blanking pipe and so on.

4, petroleum, chemical, mining, coal, coal washing plants, smelting, paper making, aluminum, building materials, powder engineering, food machinery and other processing and conveying materials pipes

Hoop strength is the resistance against radial pressure. The strength of the ceramic -lined steel composite pipe is 300 to 500MPa.