| Product: | Casing Pipe, Oil Casing, API Casing, Well Casing, Casing |

| Application: | Used for oil casing and tubing in oil wells as well as sidewall |

| Size: | OD: 114.3mm-508mm |

| WT: 5-16mm | |

| LENGTH: R1, R2, R3 | |

| Pipe Standard: | API 5CT PSL1/PSL2 J55,K55,N80-1,N80-Q, |

| API 5CT PSL1/PSL2 L80-1, L80-9Cr,L80-13Cr,C90, C95, P110, Q125 | |

| Thread: | NUE, EUE, STC, LTC, BTC, XC,HYDRILL CS |

| Special Service | Sweet Service, Sour Service, Anti-H2S, NACE MR0175/ISO15156 |

| Accessories: | Pup Joint, Coupling, Drill Collar, Crossover etc. |

Introduction

Introduction

A casing pipe is a hollow steel tube that is typically rammed into place through the earth by using a hydraulic or pneumatic jack. After being driven, the displaced soil is removed and the product pipe, or carrier pipe, is inserted inside the steel tube.

Available Sizes

Category:ERW, HFW or SMLS

Standards:API 5CT PSL1/PSL2 J55,K55,N80-1,N80-Q,API 5CT PSL1/PSL2 L80-1, L80-9Cr,L80-13Cr,C90, C95, P110, Q125

Steel Grade:H40, J55, K55, N80

Connections

API 5CT is applicable to following connections which complied with API SPEC 5B:

• SC:Short round thread casing

• LC:Long ound thread casing

• BC:Buttress thread casing

• NU: Non-upset tubing

• EU:External upset tubing

Specification

Specification

|

DN |

O. D. |

Weight |

W. T. |

End Machining Form |

||||||||

|

Steel Grade |

||||||||||||

|

in |

mm |

lb/ft |

kg/m |

in |

mm |

H40 |

J55 |

L80 |

N80 |

C90 |

P110 |

|

|

K55 |

T95 |

|||||||||||

|

4-1/2 |

4.500 |

114.3 |

9.50 |

14.14 |

0.205 |

5.21 |

PS |

PS |

– |

– |

– |

– |

|

10.50 |

15.63 |

0.224 |

5.69 |

– |

PSB |

– |

– |

– |

– |

|||

|

11.60 |

17.26 |

0.250 |

6.35 |

– |

PSLB |

PLB |

PLB |

PLB |

PLB |

|||

|

13.50 |

20.09 |

0.290 |

7.37 |

– |

– |

PLB |

PLB |

PLB |

PLB |

|||

|

15.10 |

22.47 |

0.337 |

9.56 |

– |

– |

– |

– |

– |

PLB |

|||

|

5 |

5.000 |

127 |

11.50 |

17.11 |

0.220 |

5.59 |

– |

PS |

– |

– |

– |

– |

|

13.00 |

19.35 |

0.253 |

6.43 |

– |

PSLB |

– |

– |

– |

– |

|||

|

15.00 |

22.32 |

0.296 |

7.52 |

– |

PSLB |

PLB |

PLB |

PLBE |

PLB |

|||

|

18.00 |

26.79 |

0.362 |

9.19 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

21.40 |

31.85 |

0.437 |

11.10 |

– |

– |

PLB |

PLB |

PLB |

PLB |

|||

|

23.20 |

34.53 |

0.478 |

12.14 |

– |

– |

– |

– |

PLB |

– |

|||

|

24.10 |

35.86 |

0.500 |

12.70 |

– |

– |

– |

– |

PLB |

– |

|||

|

5-1/2 |

5.500 |

139.7 |

14.00 |

20.83 |

0.244 |

6.20 |

PS |

PS |

– |

– |

– |

– |

|

15.50 |

23.07 |

0.275 |

6.98 |

– |

PSLB |

– |

– |

– |

– |

|||

|

17.00 |

25.30 |

0.304 |

7.72 |

– |

PSLB |

PLB |

PLB |

PLBE |

PLB |

|||

|

20.00 |

29.76 |

0.361 |

9.17 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

23.00 |

34.23 |

0.415 |

10.54 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

26.80 |

39.88 |

0.500 |

12.70 |

– |

– |

– |

– |

– |

– |

|||

|

29.70 |

44.20 |

0.562 |

14.27 |

– |

– |

– |

– |

– |

– |

|||

|

32.60 |

48.51 |

0.625 |

15.88 |

– |

– |

– |

– |

– |

– |

|||

|

35.30 |

52.53 |

0.687 |

17.45 |

– |

– |

– |

– |

– |

– |

|||

|

38.00 |

56.55 |

0.750 |

19.05 |

– |

– |

– |

– |

– |

– |

|||

|

40.50 |

60.27 |

0.812 |

20.62 |

– |

– |

– |

– |

– |

– |

|||

|

43.10 |

64.14 |

0.875 |

22.22 |

– |

– |

– |

– |

– |

– |

|||

|

6-5/8 |

6.625 |

168.28 |

20.00 |

29.76 |

0.288 |

7.32 |

PS |

PSLB |

– |

– |

– |

– |

|

24.00 |

35.72 |

0.352 |

8.94 |

– |

PSLB |

PLB |

PLB |

PLBE |

PLB |

|||

|

28.00 |

41.67 |

0.417 |

10.59 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

32.00 |

47.62 |

0.475 |

12.06 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

7 |

7.000 |

177.8 |

17.00 |

25.30 |

0.231 |

5.87 |

PS |

– |

– |

– |

– |

– |

|

20.00 |

29.76 |

0.272 |

6.91 |

PS |

PS |

– |

– |

– |

– |

|||

|

23.00 |

34.23 |

0.317 |

8.05 |

– |

PSLB |

PLB |

PLB |

PLBE |

– |

|||

|

26.00 |

38.69 |

0.362 |

9.19 |

– |

PSLB |

PLB |

PLB |

PLBE |

PLB |

|||

|

29.00 |

43.16 |

0.408 |

10.36 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

32.00 |

47.62 |

0.453 |

11.51 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

35.00 |

52.09 |

0.498 |

12.65 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

38.00 |

56.55 |

0.540 |

13.72 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

42.70 |

63.54 |

0.625 |

15.88 |

– |

– |

– |

– |

– |

– |

|||

|

46.40 |

69.05 |

0.687 |

17.45 |

– |

– |

– |

– |

– |

– |

|||

|

50.10 |

74.56 |

0.750 |

19.05 |

– |

– |

– |

– |

– |

– |

|||

|

53.60 |

79.77 |

0.812 |

20.62 |

– |

– |

– |

– |

– |

– |

|||

|

57.10 |

84.97 |

0.875 |

22.22 |

– |

– |

– |

– |

– |

– |

|||

|

7-5/8 |

7.625 |

193.68 |

24.00 |

35.72 |

0.300 |

7.62 |

PS |

– |

– |

– |

– |

– |

|

26.40 |

39.29 |

0.328 |

8.33 |

– |

PSLB |

PLB |

PLB |

PLBE |

PLB |

|||

|

29.70 |

44.20 |

0.375 |

9.52 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

33.70 |

50.15 |

0.430 |

10.92 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

39.00 |

58.05 |

0.500 |

12.70 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

42.80 |

63.69 |

0.562 |

14.27 |

– |

– |

PLB |

PLB |

PLB |

PLB |

|||

|

45.30 |

67.41 |

0.595 |

15.11 |

– |

– |

PLB |

PLB |

PLB |

PLB |

|||

|

47.10 |

70.09 |

0.625 |

15.88 |

– |

– |

PLB |

PLB |

PLB |

PLB |

|||

|

51.20 |

76.19 |

0.687 |

17.45 |

– |

– |

– |

– |

– |

– |

|||

|

55.30 |

80.30 |

0.750 |

19.05 |

– |

– |

– |

– |

– |

– |

|||

|

8-5/8 |

8.625 |

219.08 |

24.00 |

35.72 |

0.264 |

6.71 |

– |

PS |

– |

– |

– |

– |

|

28.00 |

41.62 |

0.304 |

7.72 |

PS |

– |

– |

– |

– |

– |

|||

|

32.00 |

47.62 |

0.352 |

8.94 |

PS |

PSLB |

– |

– |

– |

– |

|||

|

36.00 |

53.57 |

0.400 |

10.16 |

– |

PSLB |

PLB |

PLB |

PLBE |

PLB |

|||

|

40.00 |

59.53 |

0.450 |

11.43 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

44.00 |

65.48 |

0.500 |

12.70 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

49.00 |

72.92 |

0.557 |

14.15 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

9-5/8 |

9.625 |

244.48 |

32.30 |

48.07 |

0.312 |

7.92 |

PS |

– |

– |

– |

– |

– |

|

36.00 |

53.57 |

0.352 |

8.94 |

PS |

PSLB |

– |

– |

– |

– |

|||

|

40.00 |

59.53 |

0.395 |

10.03 |

– |

PSLB |

PLB |

PLB |

PLBE |

– |

|||

|

43.50 |

64.73 |

0.435 |

11.05 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

47.00 |

69.94 |

0.472 |

11.99 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

53.50 |

79.62 |

0.545 |

13.84 |

– |

– |

PLB |

PLB |

PLBE |

PLB |

|||

|

58.40 |

86.91 |

0.595 |

15.11 |

– |

– |

PLB |

PLB |

PLB |

PLB |

|||

|

59.40 |

88.40 |

0.609 |

15.47 |

– |

– |

– |

– |

– |

– |

|||

|

64.90 |

96.58 |

0.672 |

17.07 |

– |

– |

– |

– |

– |

– |

|||

|

70.30 |

104.62 |

0.734 |

18.64 |

– |

– |

– |

– |

– |

– |

|||

|

75.60 |

112.50 |

0.797 |

20.24 |

– |

– |

– |

– |

– |

– |

|||

|

10-3/4 |

10.750 |

273.05 |

32.75 |

48.74 |

0.279 |

7.09 |

PS |

– |

– |

– |

– |

– |

|

40.50 |

60.27 |

0.350 |

8.89 |

PS |

PSB |

– |

– |

– |

– |

|||

|

15.50 |

67.71 |

0.400 |

10.16 |

– |

PSB |

– |

– |

– |

– |

|||

|

51.00 |

75.90 |

0.450 |

11.43 |

– |

PSB |

PSB |

PSB |

PSBE |

PSB |

|||

|

55.50 |

82.59 |

0.495 |

12.57 |

– |

– |

PSB |

PSB |

PSBE |

PSB |

|||

|

60.70 |

90.33 |

0.545 |

13.84 |

– |

– |

– |

– |

PSBE |

PSB |

|||

|

65.70 |

97.77 |

0.595 |

15.11 |

– |

– |

– |

– |

PSB |

PSB |

|||

|

73.20 |

108.93 |

0.672 |

17.07 |

– |

– |

– |

– |

– |

– |

|||

|

79.20 |

117.86 |

0.734 |

18.64 |

– |

– |

– |

– |

– |

– |

|||

|

85.30 |

126.94 |

0.797 |

20.24 |

– |

– |

– |

– |

– |

– |

|||

|

11-3/4 |

11.750 |

|

42.00 |

62.50 |

0.333 |

8.46 |

PS |

– |

– |

– |

– |

– |

|

47.00 |

69.94 |

0.375 |

20.24 |

– |

– |

– |

– |

– |

– |

|||

|

54.00 |

80.36 |

0.435 |

8.46 |

– |

– |

– |

– |

– |

– |

|||

|

60.00 |

89.29 |

0.489 |

9.53 |

– |

– |

– |

– |

– |

– |

|||

|

65.00 |

96.73 |

0.534 |

11.05 |

– |

– |

– |

– |

– |

– |

|||

|

71.00 |

105.66 |

0.582 |

14.42 |

– |

– |

– |

– |

– |

– |

|||

|

13-3/8 |

13.375 |

339.73 |

48.00 |

71.43 |

0.330 |

8.38 |

PS |

– |

– |

– |

– |

– |

|

54.50 |

81.10 |

0.380 |

9.65 |

– |

PSB |

– |

– |

– |

– |

|||

|

61.00 |

90.78 |

0.430 |

10.92 |

– |

PSB |

– |

– |

– |

– |

|||

|

68.00 |

101.19 |

0.480 |

12.19 |

– |

PSB |

PSB |

PSB |

PSB |

PSB |

|||

|

72.00 |

107.15 |

0.514 |

13.06 |

– |

– |

PSB |

PSB |

PSB |

PSB |

|||

|

16 |

16.000 |

406.4 |

65.00 |

96.73 |

0.375 |

9.53 |

PS |

– |

– |

– |

– |

– |

|

75.00 |

111.61 |

0.438 |

11.13 |

– |

PSB |

– |

– |

– |

– |

|||

|

84.00 |

125.01 |

0.495 |

12.57 |

– |

PSB |

– |

– |

– |

– |

|||

|

109.00 |

162.21 |

0.656 |

16.66 |

– |

P |

P |

P |

– |

P |

|||

|

18-5/8 |

18.625 |

473.08 |

87.50 |

130.21 |

0.435 |

11.05 |

PS |

PSB |

– |

– |

– |

– |

|

20 |

20.000 |

508 |

94.00 |

139.89 |

0.438 |

11.13 |

PSL |

PSLB |

– |

– |

– |

– |

|

106.50 |

158.49 |

0.500 |

12.70 |

– |

PSLB |

– |

– |

– |

– |

|||

|

133.00 |

197.93 |

0.635 |

16.13 |

– |

PSLB |

– |

– |

– |

– |

|||

|

P——Plain;S——Short-thread;L——Long-thread;B——Buttress thread;E——Extreme thread |

||||||||||||

Chemical compositions of casing pipe

Chemical compositions of casing pipe

|

Standard |

Grade |

Chemical compositions(%) |

|||||||||

|

API SPEC 5CT |

J55 |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

V |

|

K55 |

0.34~0.39 |

0.20~0.35 |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

/ |

/ |

|

|

N80 |

0.34~0.38 |

0.20~0.35 |

1.45~1.70 |

≤0.020 |

≤0.015 |

≤0.15 |

/ |

/ |

/ |

0.11~0.16 |

|

|

L80 |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.010 |

12.0~14.0 |

≤0.20 |

≤0.20 |

/ |

/ |

|

|

P110 |

0.26~0.395 |

0.17~0.37 |

0.40~0.70 |

≤0.020 |

≤0.010 |

0.80~1.10 |

≤0.20 |

≤0.20 |

0.15~0.25 |

≤0.08

|

|

Mechanical properties of casing pipe

Mechanical properties of casing pipe|

Grade |

Type |

Total elongation under load (%) |

Yield strength (min) |

Yield strength (max) |

Tensile strength min Mpa |

Hardness Max (HRC) |

Hardness Max(HBW) |

|

J55 |

- |

0.5 |

379 |

552 |

517 |

- |

- |

|

K55 |

- |

0.5 |

379 |

552 |

655 |

- |

- |

|

N80 |

1 |

0.5 |

552 |

758 |

689 |

- |

- |

|

N80 |

Q |

0.5 |

552 |

758 |

689 |

- |

- |

|

L80 |

1 |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

L80 |

9Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

L80 |

13Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

|

C90 |

- |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

|

C95 |

- |

0.5 |

655 |

758 |

724 |

- |

- |

|

T95 |

- |

0.5 |

655 |

758 |

724 |

25.4 |

255 |

|

P110 |

- |

0.6 |

758 |

965 |

862 |

- |

- |

|

Q125 |

All |

0.65 |

862 |

1034 |

931 |

- |

- |

Our factory

Our factory

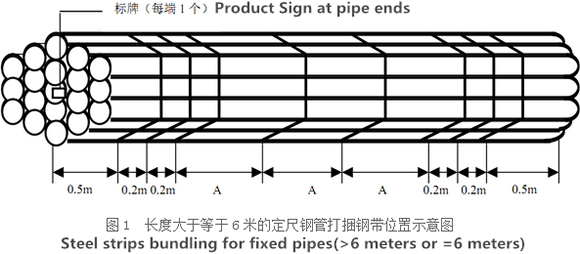

Packing

Packing

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.Our packing can meet any needs of the customers.

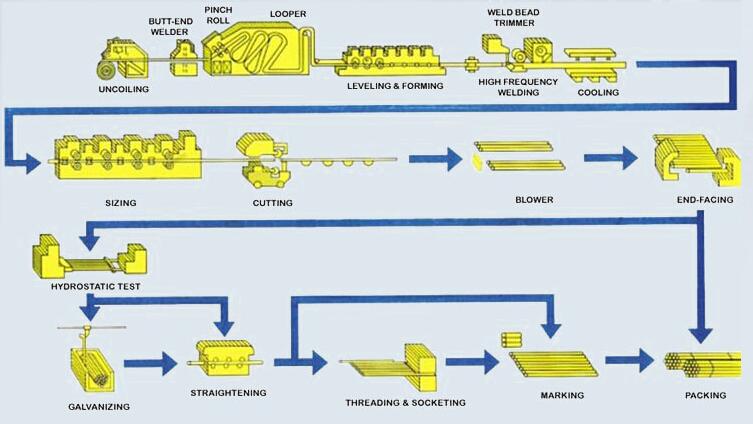

Manufacture Process

Manufacture Process

Equipment

Equipment

If you have any inquiries and questions, please contact United Steel Industry Co.,Ltd

at any time. Thanks in advance. Welcome! Email :Sales@united-steel.com