Annealed, Pickling, Polished

Product:

Stainless Steel Strip Coil, 304 Stainless Steel Coil, 316L Stainless Steel Coil

Application:

In Chemical Industry, Coal, Oil Field Open Machine, Building Materials Heat-resistant Parts

Specification:

WT: Cold Rolled Thickness: 0.4 ~ 3.0mm

Hot Rolled Thickness: 3.0 ~ 80.0mm

Standard

ASTM A213, ASTM A240, ASTM A312, ASTM A789, JIS G3459

Steel Grades

201, 202, 304, 314L, 316, 316L, 310S, 317L, 321, 409L, 430

Process Method

Cold Rolled, Hot Rolled

Surface

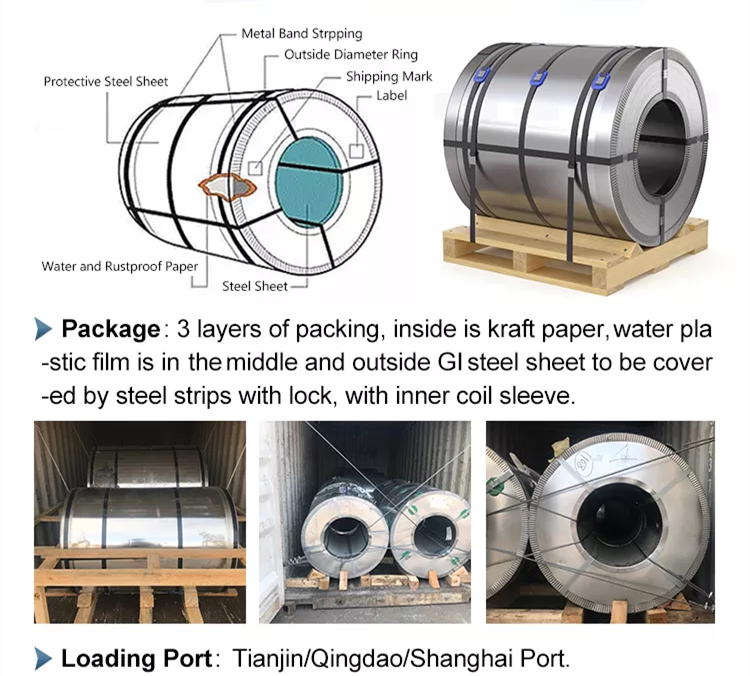

Packing

Waterproof Paper Wrapped, Packed in Wooden Cabins

Specification

Specification

|

Items |

Stainless Steel Coil |

|||||

|

Standard |

GB/T14976-2002、GB13296-91、GB9948-88 、ASTM/ASME A213/SA213、ASTM/ASME A312/SA312、 |

|||||

|

ASTM/ASME A269/SA269、DIN 17458-85、DIN 17456-85、JIS G 3459、 |

||||||

|

JIS G 3463、JIS G 3448、JIS G 344 |

||||||

|

Size |

Width: 3.5mm~1550mm |

|||||

|

Thickness: 0.025mm~4mm |

||||||

|

Industrial process |

hot rolled,hot expanded,cold drawn,and hot galvanized |

|||||

|

Tolerance |

a) Outer Diameter:6-32mm:+/- 0.2mm, 32-38:+/-0.15mm,42-60:+/-0.20mm,60mm:+/-0.25mm |

|||||

|

b) Thickness: +/- 10% |

||||||

|

c) Length: +/- 5mm |

||||||

|

Surface |

180G, 240G, 320G Satin / Hairline |

|||||

|

400G, 600G Mirror finish |

||||||

|

Application |

steel bridge,boiler plate,shipbuilding steel,steel armor,automotive steel, |

|||||

|

roof plate,structural Steel,electrical steel etc. |

||||||

|

Test |

Squash test, extended test, water pressure test, crystal rot test, heat treatment, NDT |

|||||

|

Material Composition |

|

201 |

202 |

304 |

316L |

430 |

|

Chemical Composition |

C |

≤0.15 |

≤0.15 |

≤0.08 |

≤0.035 |

≤0.12 |

|

Si |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 |

|

|

Mn |

5.5-7.5 |

7.5-10 |

≤2.00 |

≤2.00 |

≤1.00 |

|

|

P |

≤0.06 |

≤0.06 |

≤0.045 |

≤0.045 |

≤0.040 |

|

|

S |

≤0.03 |

≤0.03 |

≤0.030 |

≤0.030 |

≤0.030 |

|

|

Cr |

13-15 |

14-17 |

18-20 |

16-18 |

16-18 |

|

|

Ni |

0.7-1.1 |

3.5-4.5 |

8-10.5 |

|

|

|

|

Mo |

|

|

|

2.0-3.0 |

|

|

|

|

Material Item |

201 |

202 |

304 |

316 |

|

|

Mechanical Property |

Tensile Strength |

≥535 |

≥520 |

≥520 |

≥520 |

|

|

Yield Strength |

≥245 |

≥205 |

≥205 |

≥205 |

||

|

Extension |

≥30% |

≥30% |

≥35% |

≥35% |

||

|

Hardness (HV) |

<105 |

<100 |

<90 |

<90 |

||

|

Extension |

≥30% |

≥30% |

≥35% |

≥35% |

||

Material Thickness: .010"-.500"

Min/Max Slit width: .375”-84”

Min/Max ID: 20”-30”

Max OD: 84”

Slit Width Tolerance: +/-.005"

STAINLESS SHEET COIL APPLICATIONS

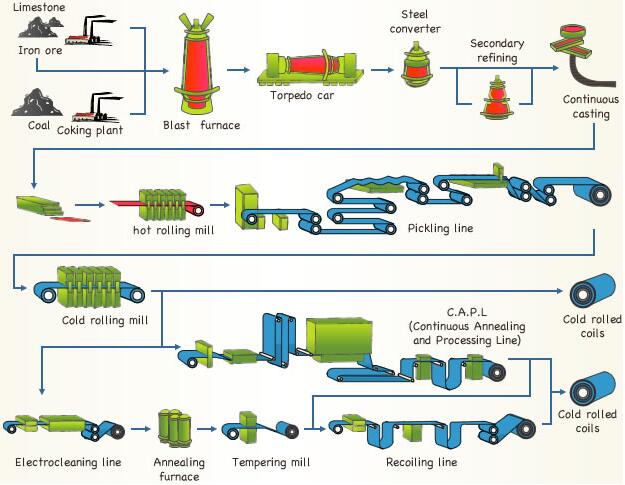

Manufacture Process

Manufacture Process

|

Grade |

Thickness (mm) |

Coil width (mm) |

Finish |

|

304/304L |

5.0 |

1500 |

2B |

|

316/316L |

6.0 |

2000 |

No. 1 |

|

304/304L |

8.0 |

1500 |

No. 1 |

|

316/316L |

10.0 |

2000 |

|

|

|

12.0 |

|

|

|

3CR12 |

5.0 |

1250 |

No. 1 |

Stainless Steel Plate

Grade

304/304L, 316/316L & 4003/3CR12.

Thickness (mm)

5.0 to 50.0.

Width (mm)

1250 (grade 4003), 1500 & 2000.

Length (mm)

3000, 6000 & customer specific cut-to-length.

Finish

2B (to 8mm) & No.1 (HRAP).

Plasma profiles

To customer drawings.

Our factory

Our factory

Packing

Packing

Manufacture Process

Manufacture Process

Equipment

Equipment

If you have any inquiries and questions, please contact United Steel Industry Co.,Ltd

at any time. Thanks in advance. Welcome! Email :Sales@united-steel.com