|

Bend Type: |

Pipe Bend, Steel Pipe Bend, Hot Bend, Induction Bend, Induction Hot Bend |

|

Material: |

Carbon Steel --- API 5L, ASME B16.49, EN 10218 Alloy Steel --- ASTM A234 |

|

Stainless Steel --- ASTM 312/403 304/304L/316/316L/613Ti/321/317L/310S |

|

|

Alloy Steel --- ASTM A234 |

|

|

Specification: |

NPS from 1/2'' to 72'', DN from 15 to 1800, |

|

Bend Radius: |

2.5D/3D/4D/5D/6D/7D/8D/9D/10D |

|

Bend Angle: |

15/30/45/60/90/135/180 deg |

|

Surface: |

Light Oiling, Black Painting, PE /3PE Anti-corrosion Coating |

|

Packing: |

Packed in Wood Cabins/Wood Tray |

Introduction

Introduction

|

Pipe Diameter (O.D) |

min. 2” (60,3 mm); max 60” (1524 mm) |

|

Seamless Bend |

(1/2″- 24″) |

|

ERW / Fabricated/ Welded Bend |

(2″- 36″) |

|

Radius |

min. 100 mm; max. 11000 mm |

|

Wall thickness |

max. 200 mm |

|

Hot Bend Heating system |

max. 1030 KW |

|

Bending capability |

15,000 metric tons per year |

|

Wall Thickness |

3mm- 40mm / SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

|

Pipe Bend Radius |

R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

|

Straight Length L |

300mm and 1500mm |

|

Pipe Bend Angle |

0°- 180° |

|

Hot Induction Bend manufacturering Standards |

· DIN, ASTM, ASME, MSS, EN, and JIS codes and standards · ASME: ANSI B16.9, ANSI B16.28, MSS-SP-43 · DIN: DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 · EN: EN10253-1, EN10253-2 |

|

Pipe Bend Standards |

· ASTM A403- ASME SA403 – Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings · ASME B16.9 – Factory-Made Wrought Fittings Buttwelding · ASME B16.25 – Buttwelding Ends ASME B16.28 – Wrought Steel Short Radius Elbows and Buttwelding Returns · MSS SP-43 – Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications · ASME B16.49 – factory-made carbon steel Pipe bend |

|

Production Grades |

Carbon Steel, API 5L, ASTM A106 Grade B, Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Copper, Cupro Nickel, Inconel, Monel, Hastelloy |

|

Value Added Services |

Epoxy & FBE Coating, Hot Dipped Galvanizing, Electro Polish, Sand Blasting, Threading, Soldering |

|

Stainless Steel Hot Induction Bend |

ASTM A403 WP316/316L, ASTM A403 WP304/304L, ASTM A182 F316L, 304L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

|

Carbon Steel Hot Induction Bend |

ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70 |

|

Alloy Steel Hot Induction Bend |

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

|

Nickel Alloy Hot Induction Bend |

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |

|

Duplex & Super Duplex Hot Induction Bend |

ASTM A 815, ASME SA 815 UNS NO S31803, S32205. UNS S32750, S32950. Werkstoff No. 1.4462 |

|

Manufacturer of induction bend |

· Bending of single-length pipe spools in multiple radius (2D, 3D, 5D) · Providing pre-fabrication of high-pressure piping systems · Heat treatment (normalizing, stress relieving, tempering, water quenching…) · End: weld end, plain end preparation and tapering · Grit blasting and painting · Pickling and passivation · Internal and external coating ( FBE, PE, PP, concrete weight coating…) |

|

Inspection for ASTM A420 WPL3 Bend |

· Visual the surface finish of 3D bend body. Such as die marks, dents, porosity, undercuts. · Measure dimensions like OD, inner diameter, wall thickness, and radius |

|

Marking Sample |

12″ Sch40 90 Degree 3D SMLS ASTM A420 WPL3 ASME B16.9 |

|

We Export to |

Contact our sales representative in following locations: · UK · USA · Germany · UAE · Singapore · Malaysia · Philippines · Saudi Arabia · Indonesia · Qatar · Vietnam · Australia · Korea · Nigeria and many others |

Hot Induction Bend Weight Calculation

Hot Induction Bend Weight Calculation

Check Induction bending process and dimensions, do not forget to compare our price with other hot induction bend manufacturer in India

Weight Calculation Formula of 5D Bend

W=0.0387 * S( D – S ) * 5* D/ 1000

W = Weight (kg/piece).

Sch = Thickness Schedule.

D = Nominal Diameter.

5D Bend Weight

Coating of ASTM A106 Gr.B Induction Bends

HCoating of ASTM A106 Gr.B Induction Bends

HCoating of ASTM A106 Gr.B Induction Bends

|

Phenolic Epoxy Coating |

Food Grade Epoxy Coatings |

|

3LPE Coating |

Fusion Bonded Epoxy Coating (FBE Coating) |

|

Internal & External Coating |

Halar Coatings |

|

Glass Flake Coatings |

Any Liquid Epoxy Coating |

|

PTFE Coating |

Elastomeric Polyurethane Coating |

Difference Between Hot Bend and Cold Bend

Difference Between Hot Bend and Cold Bend

|

Cold Bend |

Hot Bend |

|

All types of bending without heat |

Type of Hot Induction bending for precise dimensions |

|

Low cost |

It will cost you high compared to cold bending |

|

Bend to radically is not possible |

It can be bent easily |

|

Cold bending suitable fpr small bore |

Hot bending is done for larger dia piping systems |

Difference Between Hot Bend and Cold Bend

Difference Between Hot Bend and Cold Bend

|

Induction Bending Machine |

I B Mc 1 |

I B Mc 2 |

I B Mc 3 |

|

Size of Pipe |

3” - 14” |

4” - 36” |

4” - 48” |

|

Bending Radius (mm) |

1780 |

4575 |

7320 |

|

Thickness (mm) |

5 - 50 UpTo 14” Dia Pipe |

6 - 36 for 26” - 36” Dia Pipe |

8 - 32 mm for 38” - 48” Dia Pipe |

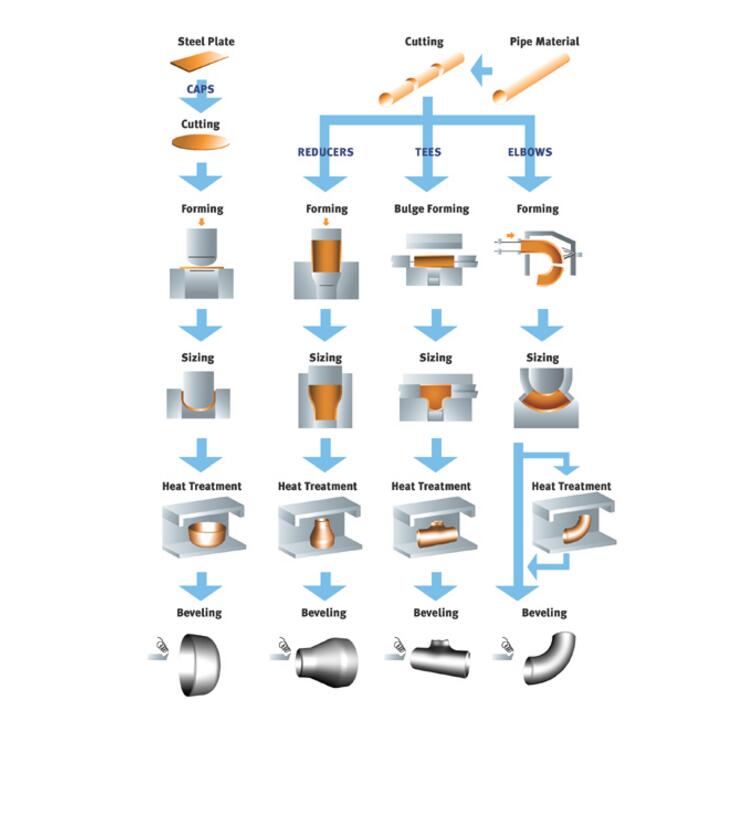

Manufacture Process

Manufacture Process

Equipment

Equipment

If you have any inquiries and questions, please contact United Steel Industry Co.,Ltd

at any time. Thanks in advance. Welcome! Email :Sales@united-steel.com