| Product: | Seamless Pipe,Seamless Carbon Steel Pipe,Carbon Steel Seamless Pipe |

| Application: | For converying gas, water & oil for Fluids Transmission |

| Size: | OD: 10.3-1219.2mm |

| WT: 1.65-60mm | |

| LENGTH: 5.8/6/11.8/12m | |

| Pipe Standard: | API 5L |

| ASTM A106 | |

| JIS G3454,G3455,G3456 | |

| DIN1629/EN10216-1 | |

| EN 10208 |

Introduction

IntroductionSeamless steel pipe, as the name suggests, is a pipe without a seam or a weld-joint. Seamless steel pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids.

The production of our seamless pipes is tightly regulated and all of the pipes we stock have been fully tested to international standards to ensure we only supply the highest quality products.

Product Details:

Size

Size

Standard

Standard

|

ASTM A53 Gr.B |

Black and hot-dipped zinc-coated steel pipes welded and seamless |

|

ASTM A106 Gr.B |

Seamless carbon steel for high temperature service |

|

ASTM SA179 |

Seamless cold-drawn low-carbon steel heat exchanger and condenser tubes |

|

ASTM SA192 |

Seamless carbon steel boiler tubes for high pressure |

|

ASTM SA210 |

Seamless Medium-carbon boiler and superheater tubes |

|

ASTM A213 |

Seamless alloy-steel boiler, superheater, and heat-exchanger tubes |

|

ASTM A333 GR.6 |

seamless and welded carbon and alloy steel pipe intended for use at low temperatures. |

|

ASTM A335 P9,P11,T22,T91 |

Seamless ferritic alloy-steel pipe for high-temperature service |

|

ASTM A336 |

Alloy steel forgings for pressure and high-temperature parts |

|

ASTM SA519 4140/4130 |

Seamless carbon for mechanical tubing |

|

API Spec 5CT J55/K55/N80/L80/P110/K55 |

Seamless steel pipe for casing |

|

API Spec 5L PSL1/PSL2 Gr.b, X42/46/52/56/65/70 |

Seamless steel pipe for line pipe |

|

DIN 17175 |

Seamless steel tube for elevated temperture |

|

DN2391 |

Cold drawn seamless prevision pipe |

|

DIN 1629 |

Seamless circular unalloyed steel tubes subject to special requirements |

Chemical Composition and Mechanical Properties

Chemical Composition and Mechanical Properties

|

standard |

Grade |

Chemical Components (%) |

Mechanical Properties |

|||||

|

C |

Si |

Mn |

P |

S |

Tensile STrength(Mpa) |

Yield STrength(Mpa) |

||

|

ASTM A53 |

A |

≤0.25 |

- |

≤0.95 |

≤0.05 |

≤0.06 |

≥330 |

≥205 |

|

B |

≤0.30 |

- |

≤1.2 |

≤0.05 |

≤0.06 |

≥415 |

≥240 |

|

|

ASTM A106 |

A |

≤0.30 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥415 |

≥240 |

|

B |

≤0.35 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥485 |

≥275 |

|

|

ASTM A179 |

A179 |

0.06-0.18 |

- |

0.27-0.63 |

≤0.035 |

≤0.035 |

≥325 |

≥180 |

|

ASTM A192 |

A192 |

0.06-0.18 |

≤0.25 |

0.27-0.63 |

≤0.035 |

≤0.035 |

≥325 |

≥180 |

|

API 5L PSL1 |

A |

0.22 |

- |

0.9 |

0.03 |

0.03 |

≥331 |

≥207 |

|

B |

0.28 |

- |

1.2 |

0.03 |

0.03 |

≥414 |

≥241 |

|

|

X42 |

0.28 |

- |

1.3 |

0.03 |

0.03 |

≥414 |

≥290 |

|

|

X46 |

0.28 |

- |

1.4 |

0.03 |

0.03 |

≥434 |

≥317 |

|

|

X52 |

0.28 |

- |

1.4 |

0.03 |

0.03 |

≥455 |

≥359 |

|

|

X56 |

0.28 |

- |

1.4 |

0.03 |

0.03 |

≥490 |

≥386 |

|

|

X60 |

0.28 |

- |

1.4 |

0.03 |

0.03 |

≥517 |

≥448 |

|

|

X65 |

0.28 |

- |

1.4 |

0.03 |

0.03 |

≥531 |

≥448 |

|

|

X70 |

0.28 |

- |

1.4 |

0.03 |

0.03 |

≥565 |

≥483 |

|

|

API 5L PSL2 |

B |

0.24 |

- |

1.2 |

0.025 |

0.015 |

≥414 |

≥241 |

|

X42 |

0.24 |

- |

1.3 |

0.025 |

0.015 |

≥414 |

≥290 |

|

|

X46 |

0.24 |

- |

1.4 |

0.025 |

0.015 |

≥434 |

≥317 |

|

|

X52 |

0.24 |

- |

1.4 |

0.025 |

0.015 |

≥455 |

≥359 |

|

|

X56 |

0.24 |

- |

1.4 |

0.025 |

0.015 |

≥490 |

≥386 |

|

|

X60 |

0.24 |

- |

1.4 |

0.025 |

0.015 |

≥517 |

≥414 |

|

|

X65 |

0.24 |

- |

1.4 |

0.025 |

0.015 |

≥531 |

≥448 |

|

|

X70 |

0.24 |

- |

1.4 |

0.025 |

0.015 |

≥565 |

≥483 |

|

|

X80 |

0.24 |

- |

1.4 |

0.025 |

0.015 |

≥621 |

≥552 |

|

Tolerances

Tolerances

Pipe types

Pipe sizes(mm)

Tolerances

Hot rolled

OD<50

±0.50mm

OD≥50

±1%

WT<4

±12.5%

WT 4~20

+15%, -12.5%

WT>20

±12.5%

Cold drawn

OD 6~10

±0.20mm

OD 10~30

±0.40mm

OD 30~50

±0.45

OD>50

±1%

WT≤1

±0.15mm

WT 1~3

+15%, -10%

WT >3

+12.5%, -10%

Application

Application

|

Types |

Application |

|

Structure Purposes |

General structure and mechanical |

|

Liquid Services |

Petroleum, gas and other fluids conveying |

|

Low and Medium Pressure Boiler Tube |

Steam and boiler manufacturing |

|

Hydraulic Pillar Service |

Hydraulic support |

|

Auto Semi-shaft Casing |

Auto sem-shaft casing |

|

Line Pipe |

Oil and gas conveying |

|

Tubing and Casing |

Oil and gas conveying |

|

Drill Pipes |

Well drilling |

|

Geological Drilling Pipe |

Geological drilling |

|

Furnace tubes, heat exchangers tubes |

Furnace tubes, heat exchangers |

|

Chilled water pipe |

Steam/condensate pipe |

Heat exchanger pipe |

Marine/offshore pipe |

Dredging pipe |

Industrial pipe |

|

Oil and gas pipe |

Fire fighting pipe |

Construction/structure pipe |

Irrigation pipe |

Drain/sewage pipe |

Boiler tube |

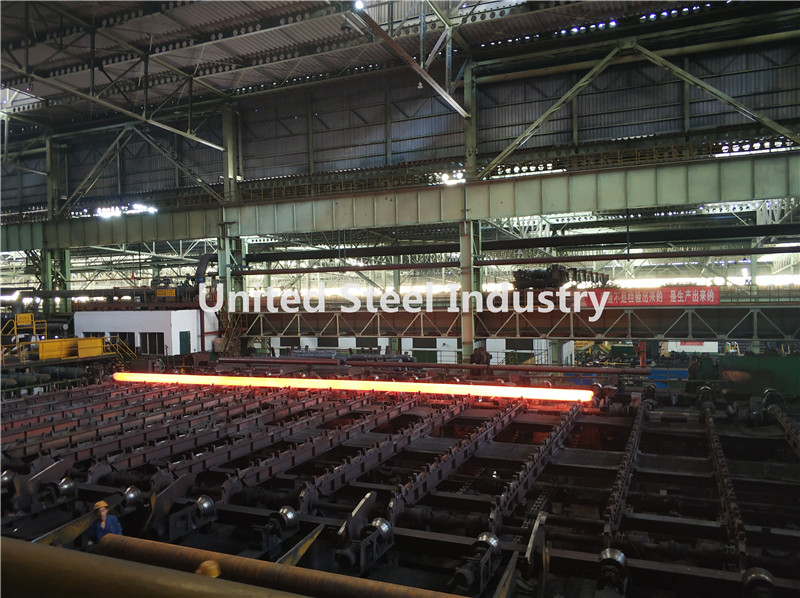

Our factory

Our factory

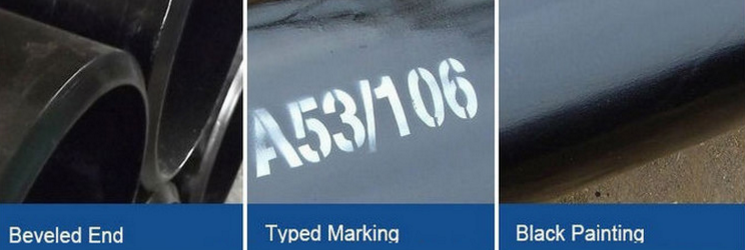

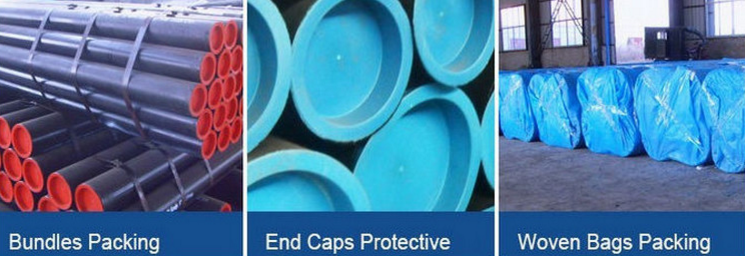

Packing

Packing

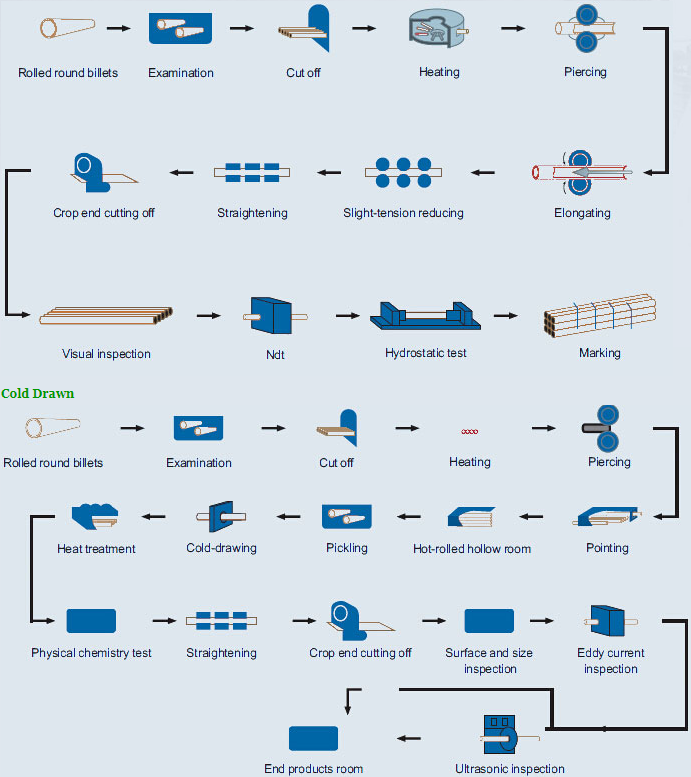

Process

Process

Equipment

Equipment

If you have any inquiries and questions, please contact United Steel Industry Co.,Ltd

at any time. Thanks in advance. Welcome! Email :Sales@united-steel.com