| Product: | LSAW pipe,Longitudinally Submerged Arc Welding Pipe |

| Application: | Used for oil/gas/water Transmission,Engineering/Offshore projects. |

| Size: | OD: 219mm-1625mm |

| WT: 6.35 mm – 60 mm | |

| LENGTH: 2 m – 18 m | |

| Pipe Standard: | API 5L PSL1/PSL2 Gr.A,Gr.B,X42,X46,X52,X56,X60,X65,X70 |

| ASTM A53 ASTM 572 ASTM A252 | |

| AN/NZS 1163 AN/NZS 1074 | |

| EN10219-1 EN10217-1 |

Introduction

Introduction

Longitudinally Submerged Arc Welding Pipe is subdivided into UOE, RBE, JCOE steel pipe according to its different forming methods. Longitudinal high-frequency welded steel pipe has the characteristics of relatively simple process and fast continuous production, and has wide use in civil construction,petrochemical, light industry and other sectors. Mostly used to transport low pressure fluids or made into various engineering components and light industrial products.

When compared UOE vs JCOE pipes, LSAW steel pipe manufacturers in China can produce more sizes as:

When compared UOE vs JCOE pipes, LSAW steel pipe manufacturers in China can produce more sizes as:

Specification

Specification

|

O.D. |

W.T. |

Length(m) |

|||||||

|

Inch |

mm |

Min.Yield Strength(Mpa) |

|||||||

|

Inch |

mm |

245(B) |

290(X42) |

360(X52) |

415(X60) |

450(X65) |

485(X70) |

555(X80) |

|

|

16 |

406 |

6.0-14.0 |

6.0-13.0 |

6.0-12.0 |

6.0-11.0 |

6.0-10.5 |

6.0-10.0 |

6.0-9.0 |

6.0-12.3 |

|

18 |

457 |

6.0-15.0 |

6.0-14.0 |

6.0-13.0 |

6.0-12.0 |

6.0-11.5 |

6.0-11.0 |

6.0-10.0 |

6.0-12.3 |

|

20 |

508 |

6.0-16.0 |

6.0-15.0 |

6.0-14.0 |

6.0-13.0 |

6.0-12.5 |

6.0-12.0 |

6.0-11.0 |

6.0-12.3 |

|

22 |

559 |

6.0-17.0 |

6.0-16.0 |

6.0-15.0 |

6.0-14.0 |

6.0-13.5 |

6.0-13.0 |

6.0-12.0 |

6.0-12.3 |

|

24 |

610 |

6.0-18.0 |

6.0-17.0 |

6.0-16.0 |

6.0-15.0 |

6.0-14.5 |

6.0-14.0 |

6.0-13.0 |

6.0-12.3 |

|

26 |

660 |

6.0-19.0 |

6.0-18.0 |

6.0-17.0 |

6.0-16.0 |

6.0-15.0 |

6.0-15.0 |

6.0-14.0 |

6.0-12.3 |

|

28 |

711 |

6.0-20.0 |

6.0-19.0 |

6.0-18.0 |

6.0-17.0 |

6.0-16.5 |

6.0-16.0 |

6.0-15.0 |

6.0-12.3 |

|

30 |

762 |

7.0-21.0 |

7.0-20.0 |

7.0-19.0 |

7.0-18.0 |

7.0-17.5 |

7.0-17.0 |

7.0-16.0 |

6.0-12.3 |

|

32 |

813 |

7.0-22.0 |

7.0-21.0 |

7.0-20.0 |

7.0-19.0 |

7.0-18.5 |

7.0-18.0 |

7.0-17.0 |

6.0-12.3 |

|

34 |

864 |

7.0-23.0 |

7.0-22.0 |

7.0-21.0 |

7.0-20.0 |

7.0-19.5 |

7.0-19.0 |

7.0-18.0 |

6.0-12.3 |

|

36 |

914 |

8.0-24.0 |

8.0-23.0 |

8.0-22.0 |

8.0-21.0 |

8.0-20.5 |

8.0-20.0 |

8.0-19.0 |

6.0-12.3 |

|

38 |

965 |

8.0-25.0 |

8.0-24.0 |

8.0-23.0 |

8.0-22.0 |

8.0-21.5 |

8.0-21.0 |

8.0-20.0 |

6.0-12.3 |

|

40 |

1016 |

8.0-26.0 |

8.0-25.0 |

8.0-24.0 |

8.0-23.0 |

8.0-22.5 |

8.0-22.0 |

8.0-21.0 |

6.0-12.3 |

|

42 |

1067 |

8.0-26.0 |

8.0-25.0 |

8.0-24.0 |

8.0-23.0 |

8.0-22.5 |

8.0-22.0 |

8.0-21.0 |

6.0-12.3 |

|

44 |

1118 |

9.0-27.0 |

9.0-26.0 |

9.0-24.5 |

9.0-23.5 |

9.0-22.8 |

9.0-22.0 |

9.0-21.0 |

6.0-12.3 |

|

46 |

1168 |

9.0-27.0 |

9.0-26.0 |

9.0-24.0 |

9.0-23.5 |

9.0-22.8 |

9.0-22.0 |

9.0-21.0 |

6.0-12.3 |

|

48 |

1219 |

9.0-28.0 |

9.0-27.0 |

9.0-25.4 |

9.0-24.0 |

9.0-23.5 |

9.0-23.0 |

9.0-22.0 |

6.0-12.3 |

|

52 |

1321 |

9.0-28.0 |

9.0-27.0 |

9.0-25.4 |

9.0-24.2 |

9.0-23.5 |

9.0-23.0 |

9.0-22.0 |

6.0-12.3 |

|

56 |

1422 |

10.0-29.0 |

10.0-28.0 |

10.0-26.0 |

10.0-24.5 |

10.0-23.8 |

10.0-23.0 |

10.0-22.0 |

6.0-12.3 |

|

60 |

1524 |

10.0-29.0 |

10.0-28.0 |

10.0-26.0 |

10.0-24.5 |

10.0-23.8 |

10.0-23.0 |

10.0-22.0 |

6.0-12.3 |

|

64 |

1626 |

10.0-30.0 |

10.0-29.0 |

10.0-27.0 |

10.0-25.4 |

10.0-24.8 |

10.0-24.0 |

10.0-23.0 |

6.0-12.3 |

|

68 |

1727 |

10.0-30.0 |

10.0-29.0 |

10.0-27.0 |

10.0-25.4 |

10.0-24.8 |

10.0-24.0 |

10.0-23.0 |

6.0-12.3 |

|

72 |

1829 |

10.0-30.0 |

10.0-29.0 |

10.0-27.0 |

10.0-25.4 |

10.0-24.8 |

10.0-24.0 |

10.0-23.0 |

6.0-12.3 |

Standard

Standard

|

ASTM A53 |

Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless |

|

API 5L |

Specification for Line Pipe(Two levels PSL 1 and PSL 2 of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries.) |

|

A252 |

Standard Specification for Welded and Seamless Steel Pipe Piles |

|

A500 |

Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes |

|

A139 |

Standard Specification for Electric-Fusion (Arc)-Welded Steel Pipe (NPS 4 and Over) |

|

A672 |

Specification for Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures |

|

A691 |

Specification for Carbon and Alloy Steel Pipe, Electric-Fusion-Welded for High-Pressure Service at High Temperatures |

|

Types |

Standard |

|||||

|

SY/T5040-2000 |

SY/T5037-2000 |

SY/T9711.1-1977 |

ASTM A252 |

AWWA C200-97 |

API 5L PSL1 |

|

|

Tube end OD deviation |

±0.5%D |

±0.5%D |

-0.79mm~+2.38mm |

<±0.1%T |

<±0.1%T |

±1.6mm |

|

Wall thickness |

±10.0%T |

D<508mm, ±12.5%T |

-8%T~+19.5%T |

<-12.5%T |

-8%T~+19.5%T |

5.0mm |

|

D>508mm, ±10.0%T |

T≥15.0mm, ±1.5mm |

|||||

Tolerance of Outside Diameter and Wall Thickness

Tolerance of Outside Diameter and Wall Thickness

|

Standard |

Grade |

Chemical Composition(max)% |

Mechanical Properties(min) |

|||||

|

C |

Mn |

Si |

S |

P |

Yield Strength

(Mpa) |

Tensile Strength

(Mpa) |

||

|

GB/T700-2006 |

A |

0.22 |

1.4 |

0.35 |

0.050 |

0.045 |

235 |

370 |

|

B |

0.2 |

1.4 |

0.35 |

0.045 |

0.045 |

235 |

370 |

|

|

C |

0.17 |

1.4 |

0.35 |

0.040 |

0.040 |

235 |

370 |

|

|

D |

0.17 |

1.4 |

0.35 |

0.035 |

0.035 |

235 |

370 |

|

|

GB/T1591-2009 |

A |

0.2 |

1.7 |

0.5 |

0.035 |

0.035 |

345 |

470 |

|

B |

0.2 |

1.7 |

0.5 |

0.030 |

0.030 |

345 |

470 |

|

|

C |

0.2 |

1.7 |

0.5 |

0.030 |

0.030 |

345 |

470 |

|

|

BS En10025 |

S235JR |

0.17 |

1.4 |

- |

0.035 |

0.035 |

235 |

360 |

|

S275JR |

0.21 |

1.5 |

- |

0.035 |

0.035 |

275 |

410 |

|

|

S355JR |

0.24 |

1.6 |

- |

0.035 |

0.035 |

355 |

470 |

|

|

DIN 17100 |

ST37-2 |

0.2 |

- |

- |

0.050 |

0.050 |

225 |

340 |

|

ST44-2 |

0.21 |

- |

- |

0.050 |

0.050 |

265 |

410 |

|

|

ST52-3 |

0.2 |

1.6 |

0.55 |

0.040 |

0.040 |

345 |

490 |

|

|

JIS G3101 |

SS400 |

- |

- |

- |

0.050 |

0.050 |

235 |

400 |

|

SS490 |

- |

- |

- |

0.050 |

0.050 |

275 |

490 |

|

|

API 5L PSL1 |

A |

0.22 |

0.9 |

- |

0.03 |

0.03 |

210 |

335 |

|

B |

0.26 |

1.2 |

- |

0.03 |

0.03 |

245 |

415 |

|

|

X42 |

0.26 |

1.3 |

- |

0.03 |

0.03 |

290 |

415 |

|

|

X46 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

320 |

435 |

|

|

X52 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

360 |

460 |

|

|

X56 |

0.26 |

1.1 |

- |

0.03 |

0.03 |

390 |

490 |

|

|

X60 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

415 |

520 |

|

|

X65 |

0.26 |

1.45 |

- |

0.03 |

0.03 |

450 |

535 |

|

|

X70 |

0.26 |

1.65 |

- |

0.03 |

0.03 |

585 |

570 |

|

Tests

Tests

-Chemical Component Analysis

-Mechanical Properties – Elongation, Yield Strength, Ultimate Tensile Strength

-Technical Properties – DWT Test, Impact Test, Blow Test, Flattening Test

-X-ray Test

-Exterior Size Inspection

-Hydrostatic Test

-UT Test

How to Use LSAW Pipe for Pipelines

How to Use LSAW Pipe for Pipelines

1. According to the specification of pipe API 5L Spec, we take testing for the basic metal and welding metal. Meanwhile, we have other Specifications. Such as DIN, EN, ASTM, and GOST. Also, the LSAW steel pipe can welded with flanges. Welding lifting eyes and other parts according to clients’ requirements.

2. It also can used as pipe boots or pile boots which acted as protecting a section.

3. Except used as pipe boots. The LSAW steel pipe is also used for transporting fluids like water, oil & gas. As well as used for offshore projects and underground constructions. These products are producing in China. And exported to other countries. For example Australia, Canada, South American, Europe, Malaysia, India, Pakistan, Africa, etc.

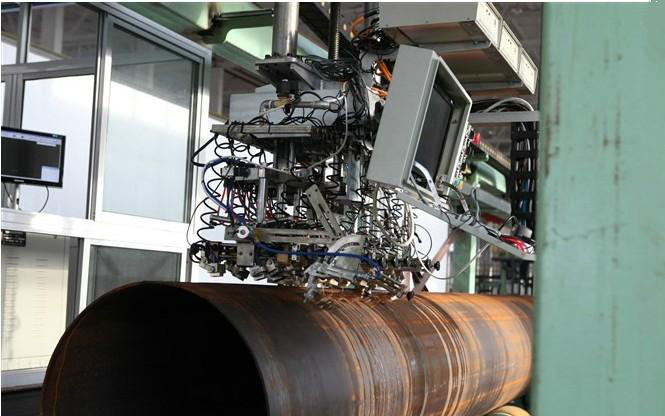

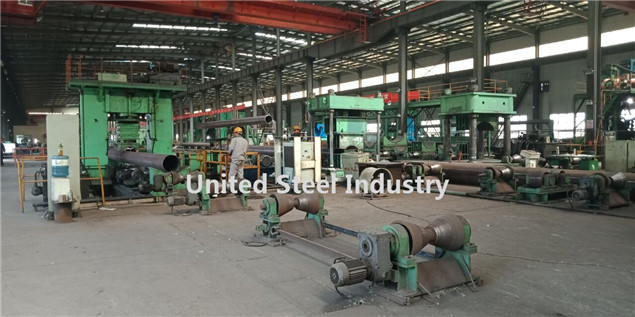

Our factory

Our factory

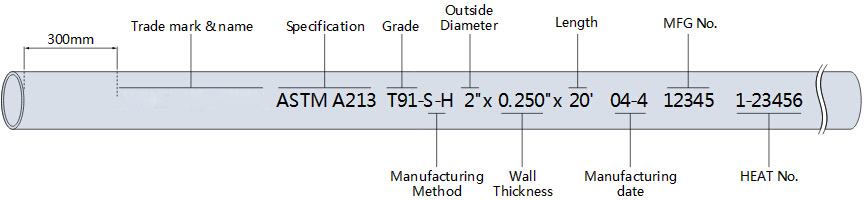

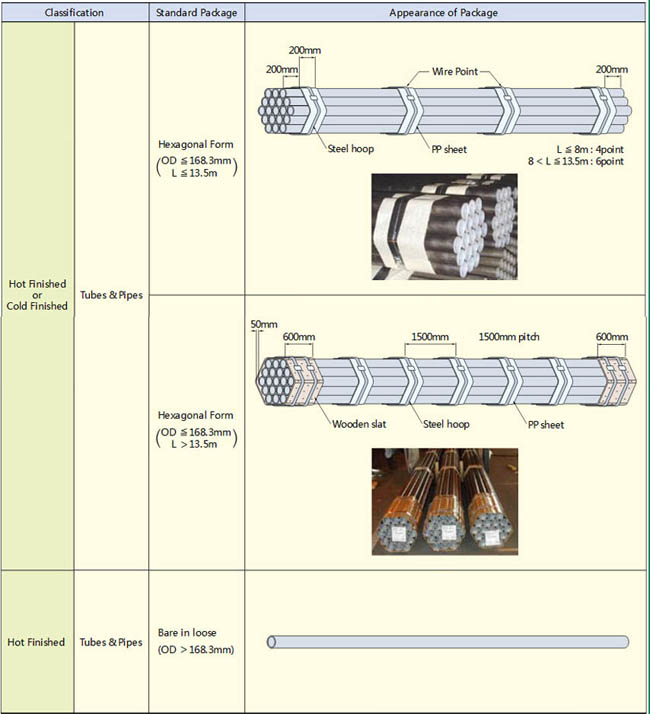

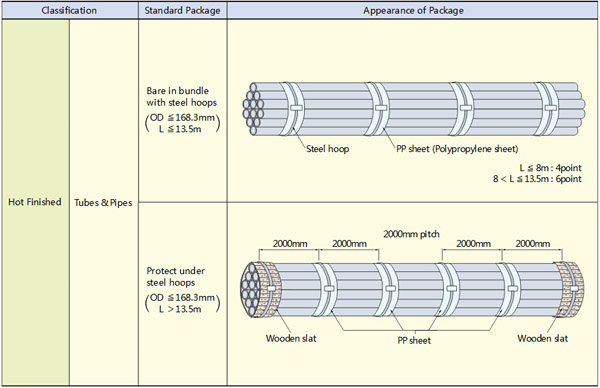

Packing

Packing

Process

Process

Equipment

Equipment

If you have any inquiries and questions, please contact United Steel Industry Co.,Ltd

at any time. Thanks in advance. Welcome! Email :Sales@united-steel.com