-

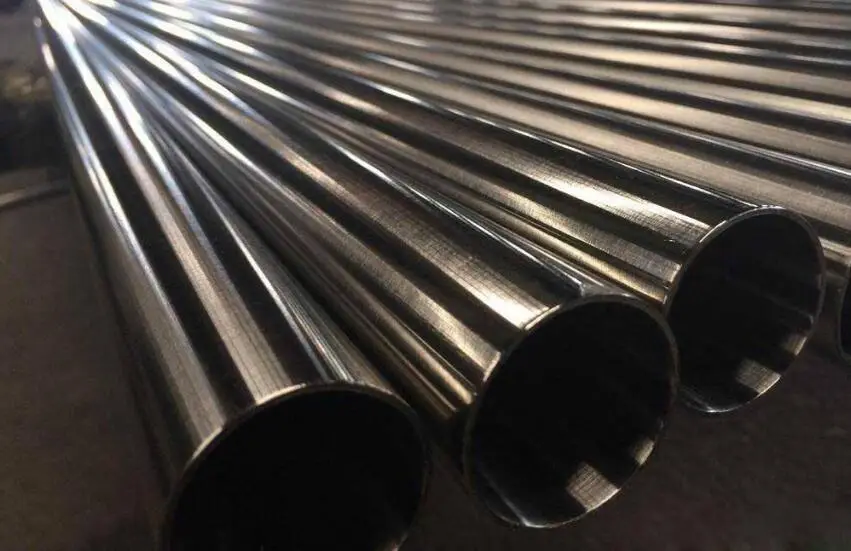

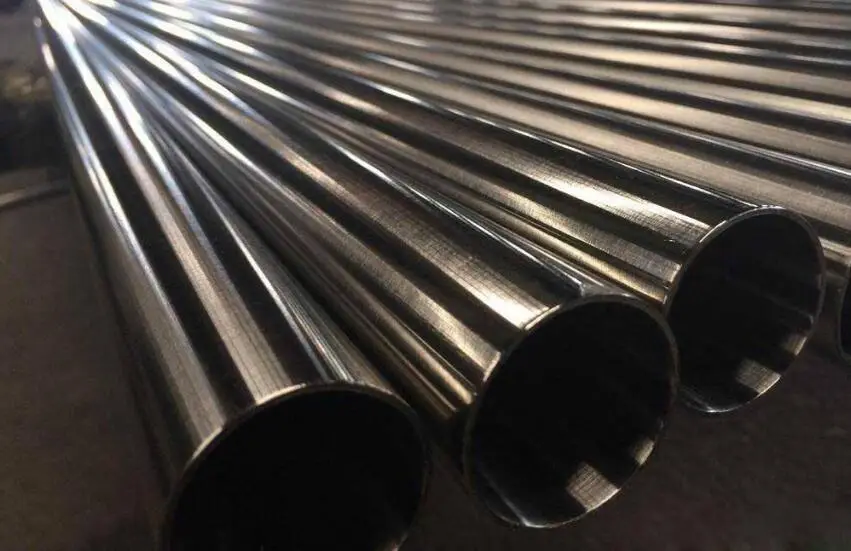

Stainless steel pipes are essential components across a wide range of industries due to their excellent corrosion resistance and mechanical properties. Among them, the D90 seamless stainless steel pipe, with its precise dimensions and high-quality finish, stands out as a prime example of advanced stainless steel technology. This article explores the manufacturing process and diverse application areas of the D90 seamless stainless steel pipe.

-

The heat treatment process is crucial in enhancing the mechanical properties, corrosion resistance, and microstructure of stainless steel pipes, making it an essential step in both their manufacturing and application. The type of stainless steel dictates the appropriate heat treatment procedures. Here are some common heat treatment processes for various stainless steel pipes.

-

Material Standard:ASTM A312

Grade No.:TP317L

Type:seamless & Welded tubes

End:Beveled End,Plain End

-

Today, United Steel will discuss about the key difference between Seamless and ERW Stainless Steel Pipe

-

Stainless steel seamless steel pipe is a long steel material with a hollow section and no seams around it.

-

What are the types and uses of stainless steel pipes?

-

316L stainless steel pipe is a kind of hollow long round steel, which is mainly used in industrial transportation pipelines such as petroleum, chemical industry, medical treatment, food, light industry, mechanical instrument, etc., as well as mechanical structural components. In addition, when the bending and torsional strength are the same, the weight is lighter, so it is also widely used in the manufacture of mechanical parts and engineering structures. It is also commonly used to produce various conventional weapons, barrels, shells, etc.

-

Choose to buy stainless steel pipes 1. Identify whether the steel stamped material "304" is printed on the surface of the pipe, and obtain the stainless steel pipe manufacturer's quality certificate and quality assurance certificate.

-

Most stainless steel products require good corrosion resistance. Some foreign merchants also conduct corrosion resistance tests on the products: use NACL aqueous solution to heat to boiling, pour the solution after a period of time, wash and dry, and weigh the weight loss to determine the damage. Corrosion degree (note: when the product is polished, because the emery cloth or sandpaper contains Fe components, it will cause rust spots on the surface during the test)

-

Stainless steel pipe is a hollow long round steel, which is widely used in petroleum, chemical, medical, food, light industry, machinery and instrumentation and other industrial pipelines and mechanical structural parts. Stainless steel pipe is a kind of economical cross-section steel. It is an important product in the steel industry. It usually accounts for about 8%-16% of the total steel. It has a wide range of applications in the national economy and is itself a saving The economic section of metal steel is an important part of high-efficiency steel, especially in the oil drilling, smelting and transportation industries.

-

All series 316 stainless steel fittings, 316 stainless steel pipe fittings price list manufacturer

-

Type 304 stainless steel is one of the most common and most commonly used stainless steel grades. It is a chromium nickel austenitic alloy, which contains at least 18% chromium and 8% nickel, which contains up to 0.08% carbon. It can not be hardened by heat treatment, but cold working can produce higher tensile strength. Chromium and nickel alloys provide corrosion resistance and oxidation resistance far better than steel or iron for Type 304. It has a lower carbon content than 302, which minimizes chromium carbide precipitation due to welding and intergranular corrosion. It has excellent molding and welding characteristics. The ultimate tensile strength of the 304 type is 51500 psi, the yield strength is 20500 psi, and the elongation is 40%, 2 ". Type 304 stainless steel has many different sizes and shapes, including rods, corners, circles, plates, slots and beams. This kind of steel is used in many industries for many different purposes. Some examples are food processing equipment, kitchen equipment and appliances, panels, decorations, chemical containers, fasteners, springs and so on.

-

United Steel Industry Co.,Ltd as member of United Steel Industry Group, is one of the best manufacturers & exporters of steel pipe and pipe fittings in China.

-

Whether we transport hundreds of miles of water or pipe gas in accordance with federal standards and regulations, our steel pipes and tubular products are durable. They are applicable to the design and manufacture of applications.

-

oil pipeline,pipeline,application of pipeline

-

The pressure welded steel pipe consists of pipe, pipe fittings which include elbow, tee joint, taper pipe and other fittings, valve, flanged joint (flange, spacer as well as bolts), and these composition pieces are generally standard components, which can be fully decided by several factors such as their nominal pressure, texture of material, nominal diameter as well as wall thickness of the Welded steel pipe. And the nominal pressure of all the piping components in the same pipeline pressure grade. Thus, the nominal pressure grade of the piping components are called pipeline pressure grade in engineering.

-

Pipeline bear the effects of the pipeline transmission medium pressure and temperature, but also suffer from a variety of delivery through the heart of the impact of natural and human factors that may occur in the course of leaking or breaking all sorts of accidents. Not only due to leakage of pipeline accidents affect transport caused economic losses, but also pollute the environment. To ensure the safe operation of the pipeline and generate pipeline accident prevention should be the design, construction and operation of three aspects, including design and reasonable choice of pipe is very important. As for the pipe, the strength, toughness and weldability are three basic quality standards. It should also consider the environmental and transport medium for pipe corrosion, corrosion-resistant steel choice.