| Product: | studded tubes, welded stud tubes,studded steel tubes,studded fin tubes |

| Application: | Steel studded tubes are used instead of finned tubes for heat transfer in the petrochemical industry, generally in furnaces and boilers where the surface is exposed to a very corrosive environment and where very dirty gas streams require frequent or aggressive cleaning. |

| Size: | OD: 38 mm ~219 mm |

| WT: 4.0 mm ~20 mm /Tube Length (Mtr) :≤ 15Mtrs | |

| Fin Height: 6.0 mm ~ 38 mm | |

| Base Tube(fin) Material: |

Carbon Steel |

| Alloy Steel | |

| Stainless Steel |

Introduction

Introduction

What is a Studded Tube?

Studded tubes are a type of metal tubes. These tubes have studs welded onto the metal tube.

These studs are arranged in a specific formation throughout the length of the tube.

They are often used in boilers and refineries. As they increase the surface area for higher heat transfer they are used for reheating.

Features of a Studded Tube

Uses of Studded Tubes

Steel studded tubes are used instead of finned tubes for heat transfer in the petrochemical industry, generally in furnaces and boilers where the surface is exposed to a very corrosive environment and where very dirty gas streams require frequent or aggressive cleaning.

Specification

Specification

|

Base Tube O.D |

Base Tube Thickness (mm) |

Fin Height |

Tube Length (Mtr) |

|

(mm) |

(mm) |

||

|

38 mm ~219 mm |

4.0 mm ~20 mm |

6.0 mm ~ 38 mm |

≤ 15Mtrs |

|

Base Tube Material |

Fin Material |

|

|

|

Carbon Steel ,Alloy Steel ,Stainless Steel |

Carbon Steel ,Alloy Steel , |

|

|

|

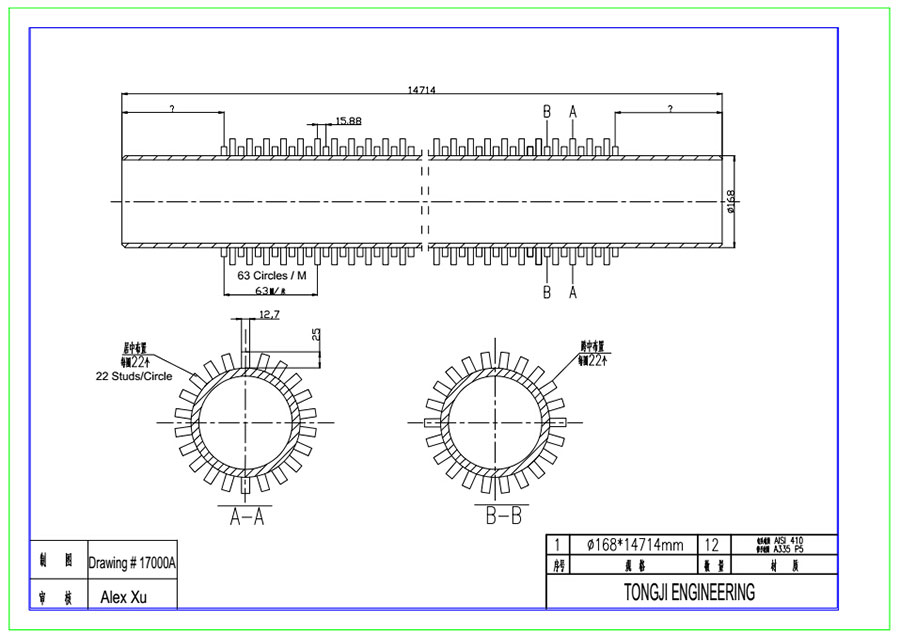

Tube O.D.: |

25~273 (mm) |

1”~10”(NPS) |

|

Tube Wall Thk.: |

3.5~28.6 (mm) |

0.14”~1.1” |

|

Tube Length: |

≤25,000 (mm) |

≤82 ft |

|

Stud Dia.: |

6~25.4 (mm) |

0.23”~1” |

|

Stud Height: |

10~35 (mm) |

0.4”~1.38” |

|

Stud Pitch: |

8~30 (mm) |

0.3”~1.2” |

|

Stud Shape: |

Cylindrical, Elliptical, Lens type |

|

|

Stud to tube surface angle: |

Vertical or angular |

|

|

Stud Material: |

C.S. (most common grade is Q235B) S.S. (most common grade are AISI 304, 316, 409, 410, 321,347 ) A.S. |

|

|

Tube Material: |

C.S. (most common grade is A106 Gr.B) S.S. (most common grade are TP304, 316, 321, 347 ) A.S.(most common grade are T/P5,9,11,22,91 ) |

|

|

* This table is used as a general guide to our capabilities, please call us for any other customized cases. |

||

Technical parameter of Studded Tube

Technical parameter of Studded Tube

|

Technical Range |

||

|

Tube OD(mm) |

Tube Thickness(mm) |

Tube Height(mm) |

|

60-219 |

4-20 |

10-38 |

|

Material & Length Range |

||

|

Tube |

Stud |

Tube Length(m) |

|

A106GrB, A335 P5/P9 A204 TP304 |

CS ANSI 410, SS304 5%Cr-1/2Mo |

1-15 |

Our factory

Our factory

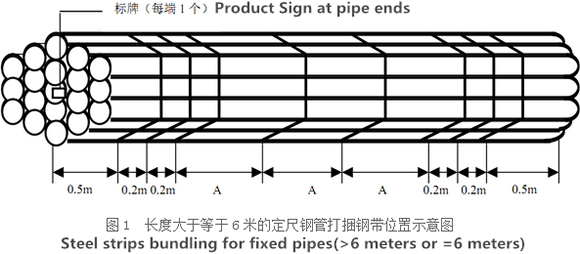

Packing

Packing

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.Our packing can meet any needs of the customers.

w

w

Manufacture Process

Manufacture Process

When an electric current is passed at the contact point of the studs and the tube, this, in turn, provides resistance.

The resistance causes heat to be producedwhich is then used for welding.

Maximum heat is generated at the interface of the tube and the studs due to maximum resistance.

No external heat source is used to weld the studs and tubes together.

The pressure is used to forge the two together instead.

Hence, they are extremely useful in the process that works under high temperature and pressure.

Equipment

Equipment

If you have any inquiries and questions, please contact United Steel Industry Co.,Ltd

at any time. Thanks in advance. Welcome! Email :Sales@united-steel.com