| Product: | Seamless Boiler Pipe, Seamless Boiler Tube |

| Application: | Used for superheated pipelines, steam pipeline, boiling water tube |

| Size: | OD: 25-127mm |

| WT: 2-12mm | |

| LENGTH: 5.8/6/11.8/12m | |

| Pipe Standard: | ASTM A192 ASTM A179 ASTM A209 ASTM A210 |

| JIS G3461 JIS G3462 JIS3463 DIN17175 EN 10216-2 | |

|

A213 T5,T9,T11,T22,T91 |

|

|

|

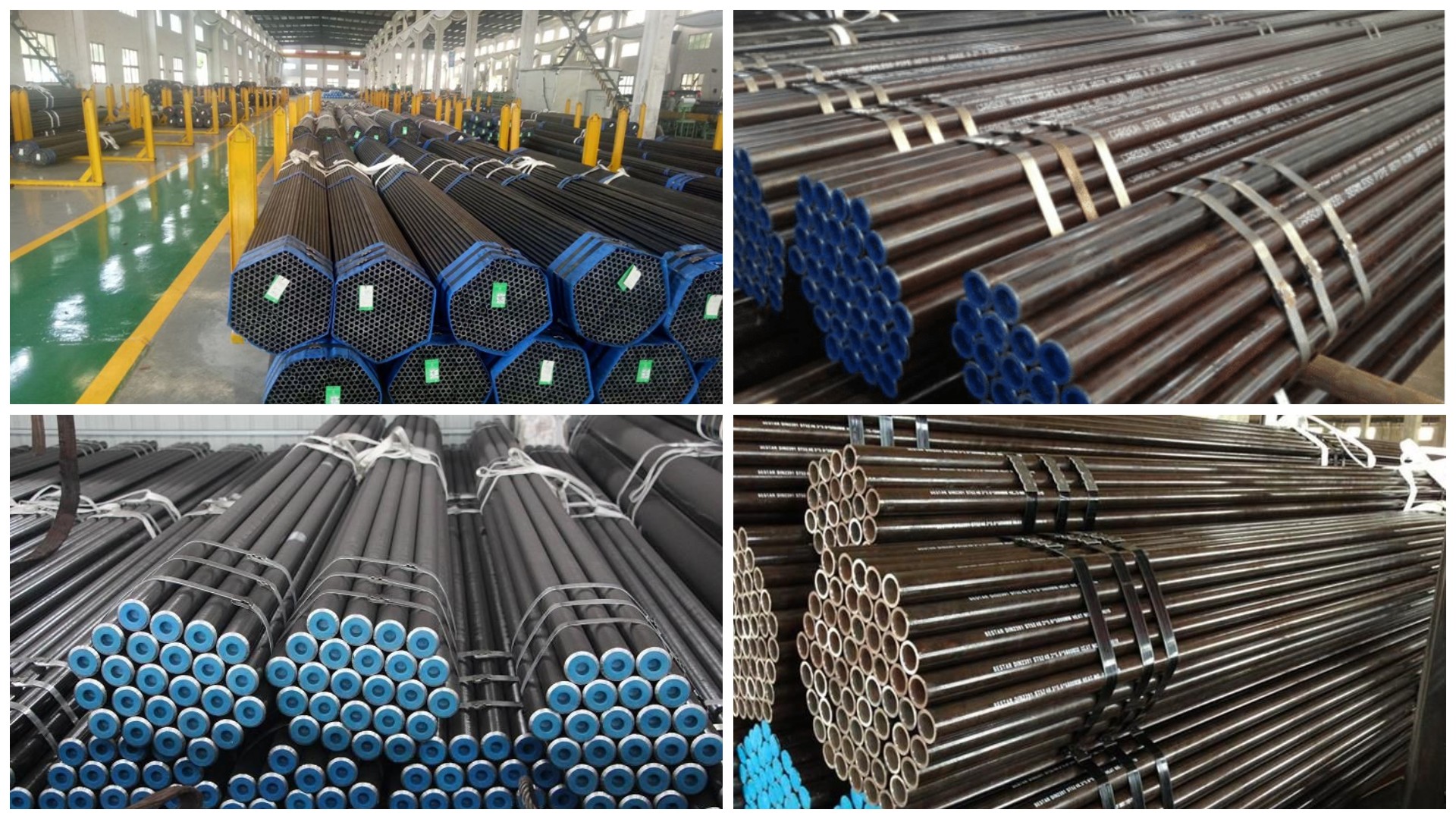

Introduction

Introduction

Boiler tubes are seamless tubes and are made of either carbon steel or alloy steel. They are widely used in steam boilers, for power generation,

in fossil fuel plants, industrial processing plants, electric power plants, etc. Boiler tubes can either be medium- pressure boiler pipe or high-pressure boiler pipe.

Types of boiler tube

Types of boiler tube

ASTM A179 Boiler Steel Pipes/Tubes ASTM A192 Boiler Seamless Steel Pipes

High Pressure Boiler Steel Pipes Low Pressure Boiler Steel Tubes

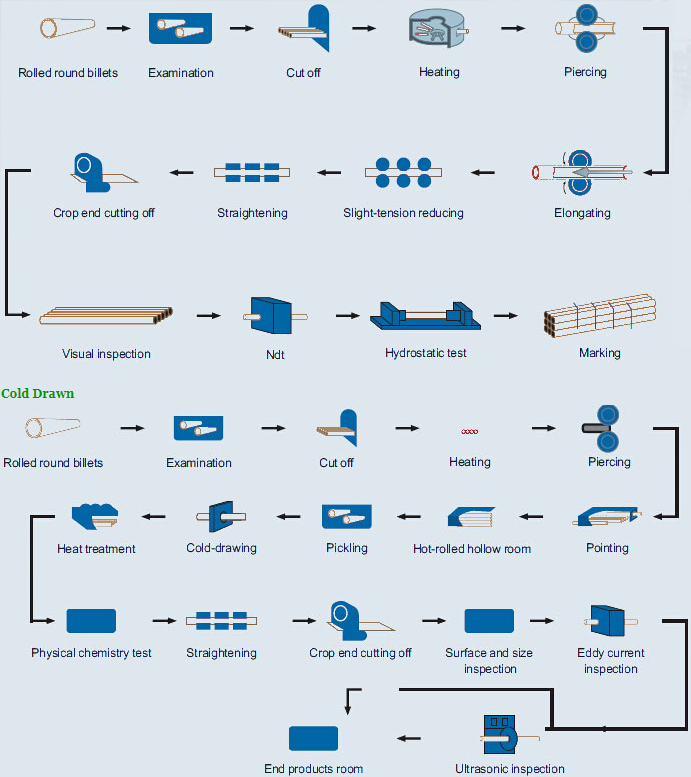

Manufacturing methods

Manufacturing methods

The manufacturing method of medium and high pressure boiler steel pipe is same with the seamless steel pipe, but there are some key manufacturing processes shall be note

Fine drawing, surface bright, hot rolling, cold drawn, heat expansion

Application:It Is Mainly Used To Make High-Quality Alloy Steel Boiler Pipe , superheated pipelines, steam pipeline, boiling water tube,Heat Exchanged Pipe, High Pressure Steam Pipe For Petroleum And Chemical Industry

Main Grade:Grade Of High-Quality Alloy Pipe :P1,P2,P5,P9,P11,P22,P91,P92 Etc

Standard: ASTM A192 ASTM A179 ASTM A209 ASTM A210;JIS G3461 JIS G3462 JIS3463 DIN17175 EN 10216-2 ;A213 T5,T9,T11,T22,T91

Specification

Specification

Size

Wall Thickness(mm)

O.D.(mm)

2

2.5

3

3.5

4

4.5

5

6

6.5-7

7.5-8

8.5-9

9.5-10

11

12

Φ25-Φ28

●

●

●

●

●

●

Φ32

●

●

●

●

●

●

Φ34-Φ36

●

●

●

●

●

●

Φ38

●

●

●

●

●

●

Φ40

●

●

●

●

●

Φ42

●

●

●

●

●

Φ45

●

●

●

●

●

●

Φ48-Φ60

●

●

●

●

●

●

●

Φ63.5

●

●

●

●

●

●

●

Φ68-Φ73

●

●

●

●

●

●

Φ76

●

●

●

●

●

●

●

●

●

●

Φ80

●

●

●

●

●

●

●

●

●

●

Φ83

●

●

●

●

●

●

●

●

●

●

Φ89

●

●

●

●

●

●

●

●

●

●

Φ95

●

●

●

●

●

●

●

●

●

●

Φ102

●

●

●

●

●

●

●

●

●

●

Φ108

●

●

●

●

●

●

●

●

●

●

Φ114

●

●

●

●

●

●

●

●

●

Φ121

●

●

●

●

●

●

●

●

●

Φ127

●

●

●

●

●

●

●

●

●

Heat treatment methods applied in the boiler pipes

Heat treatment methods applied in the boiler pipes

Test

Test

The Steel Pipe Should Be Tested Hydraulically One By One. The Maximum Test Pressure Is 20 MPa. Under The Test Pressure, The Stabilization Time Should Be Not Less Than 10 S, And The Steel Pipe Should Not Leak.

After The User Agrees, The Hydraulic Test Can Be Replaced By Eddy Current Testing Or Magnetic Flux Leakage Testing.

Nondestructive Test:

Pipes That Require More Inspection Should Be Ultrasonically Inspected One By One. After The Negotiation Requires The Consent Of The Party And Is Specified In The Contract, Other Non-Destructive Testing Can Be Added.

Flattening Test:

Tubes With An Outer Diameter Greater Than 22 Mm Shall Be Subjected To A Flattening Test. No Visible Delamination, White Spots, Or Impurities Should Occur During The Entire Experiment.

Hardness Test:

For Pipe Of Grades P91, P92, P122, And P911, Brinell, Vickers, Or Rockwell Hardness Tests Shall Be Made On A Specimen From Each Lot

Bend Test:

For Pipe Whose Diameter Exceeds NPS 25 And Whose Diameter To Wall Thickness Ratio Is 7.0 Or Less Shall Be Subjected To The Bend Test Instead Of The Flattening Test. Other Pipe Whose Diameter Equals Or Exceeds NPS 10 May Be Given The Bend Test In Place Of The Flattening Test Subject To The Approval Of The Purchaser

Our factory

Our factory

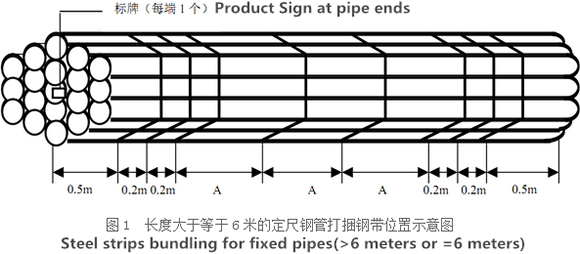

Packing

Packing

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.Our packing can meet any needs of the customers.

w

w

Manufacture Process

Manufacture Process

Equipment

Equipment

If you have any inquiries and questions, please contact United Steel Industry Co.,Ltd

at any time. Thanks in advance. Welcome! Email :Sales@united-steel.com