|

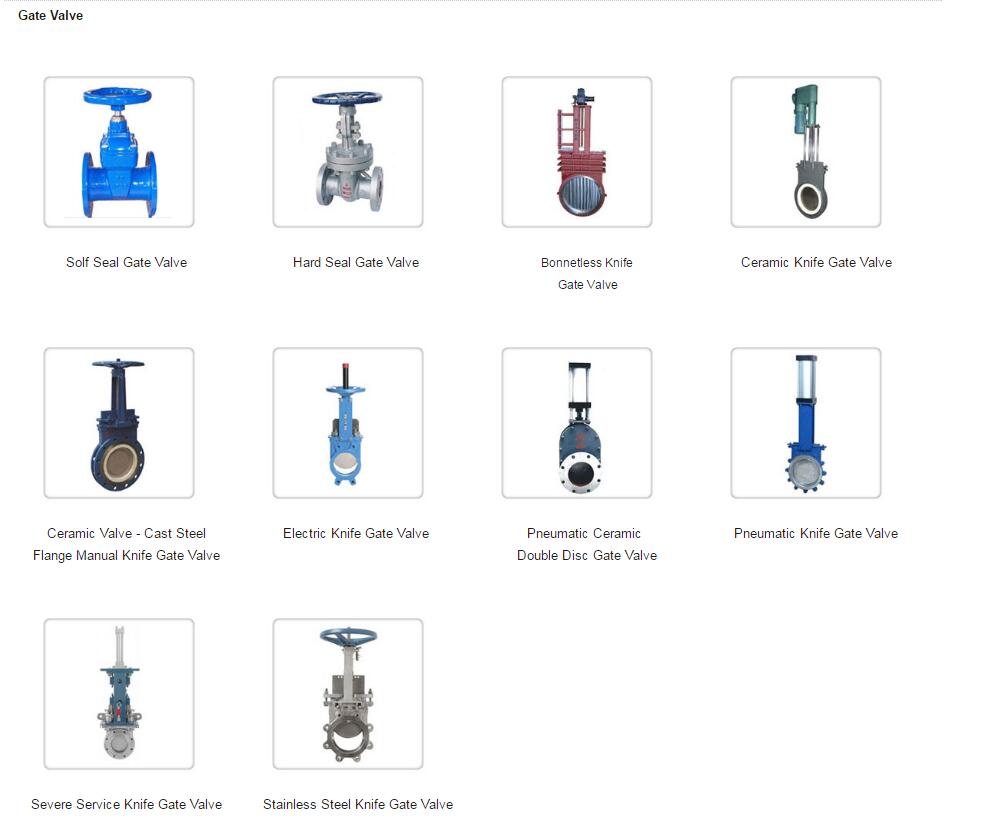

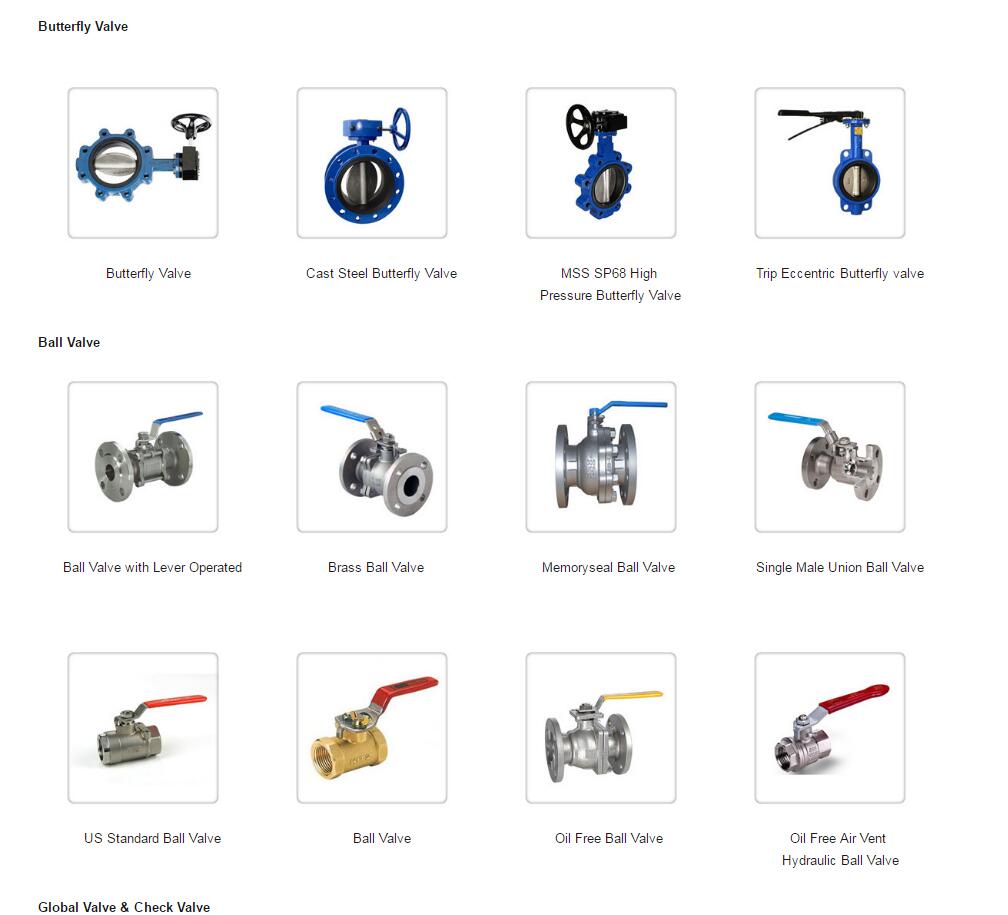

Valve Type: |

Check Valves, Ball Valves, Butterfly Valves, Gate Valves, Safety Valves |

|

Surface |

Light Oil, Black Painting |

|

Size: |

OD: 25-127mm |

|

WT: 2-12mm |

|

|

Material:

|

Carbon Steel--- ASTM A234, ASTM A105/A106/A53/A283-D, |

|

Stainless Steel --- ASTM 403 304/304L, 316/316L,316Ti,321,317L,310S |

|

|

Alloy Steel --- ASTM A234 WP 1/5/9/11/12/22/91 |

Introduction

Introduction

Uses

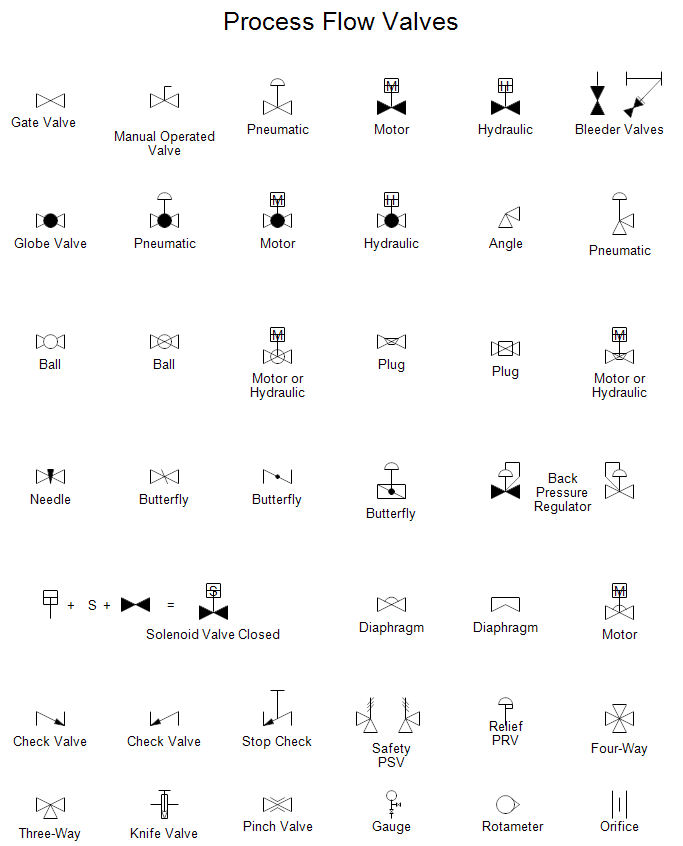

Types

Making

Making

All Flanges when possible will display a heat number, size, table, grade and dimensional standard

Plate steel flange: Plate flanges are mainly used for light duty, lower pressure or non-critical applications, commonly referring to AS2129, BS10 or AS4087 standards. The manufacturing method involves cutting and machining from plate steel

Forged steel flange: Forged Steel flanges are commonly used and specified in the Oil, Gas, Petrochemical and mining sectors, where pressure, temperature and safety considerations often specify the ANSI B16.5, ASME B16.47 or BS4504 standards. The manufacturing method involves the hot forging of suitable steels prior to final machining

Valve connections

Valve connections

There are a various methods used for connecting valves into the piping systems. They are as follows:

Flanges: Suitable rated flanges are provided with the pipe valve.

Wafer: The pipe valve is provided with suitable sealing faces. It is trapped between line flanges.

Butt Welded: The pipe valve is provided with butt weld end. This is welded into the piping system using high integrity joints.

Socket Welded: These welds allow and weld into the piping system using fillet welds.

Screwed Ends: Ends of pipe valves can be provided with female or male screwed ends . The threads can be parallel or tapered.

Compression Fittings: Ends of pipe valves can be provided with compression fittings.

Applications of pipe valves

Applications of pipe valves

The pipe valve is suitable for use across a wide spectrum of applications such as:

Industrial water treatment

Manufacture Process

Manufacture Process

Equipment

Equipment

If you have any inquiries and questions, please contact United Steel Industry Co.,Ltd

at any time. Thanks in advance. Welcome! Email :Sales@united-steel.com