| Product: | FBE (Fusion Bond Epoxy) Coated Pipe, Epoxy Coated Carbon Steel Pipe |

| Application: | Used for Coal mine,heat and power plant,oil and gas transmission |

| Standard: | DIN30670,CAN/CSA-Z245.21 |

| Size: | OD:219-2000MM |

| Pakcing: | in bundles, in loose, Nylon Strip for each bundle for piece pipe |

| Color | RAL colors coating powder |

| Service: | anti-chemical corrosion and water resistance strong |

Introduction

Introduction

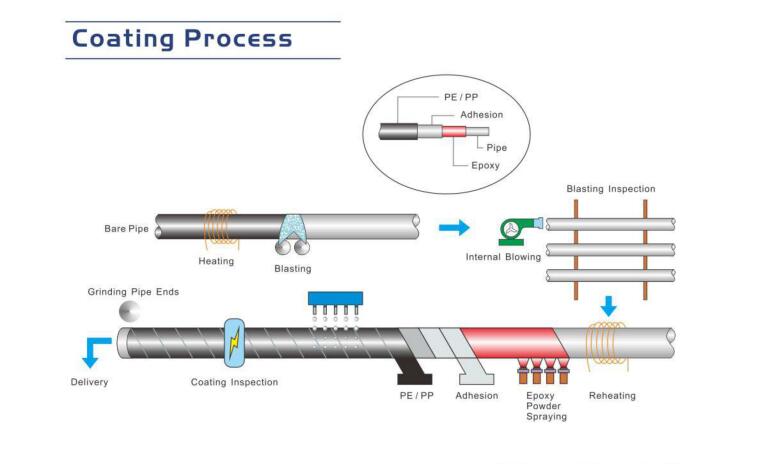

Fusion bonded epoxy(FBE) coating generally refers to a single layer of fused epoxy coating, using fused epoxy powder coating as a film-forming material. This kind of epoxy powder coating is a kind of thermosetting coating, which is made of solid epoxy resin, curing agent and various additives through mixing and grinding.Fusion bonded epoxy (FBE) coating is a powder coating broadly used to provide protection to pipelines, steel pipes and a wide range of piping bonds.FBE Coating has been used as a standard in industries for protection against corrosion.

FBE coatings have good handling characteristics; they are flexible and resistant to soil pressure.These are used in pipeline projects that have normal requirements and do not have harsh conditions.

Features of Fusion Bonded Epoxy (FBE) coated pipes:

Standards of Api 5l Epoxy Primer Coated Pipes

Standards of Api 5l Epoxy Primer Coated Pipes

|

Standard |

API 5L |

|

||

|

Grade |

PSL-1 |

API 5L – Gr.B/X42/X46/X52/X60/X70 etc. |

|

|

|

( Material) |

PSL-2 |

ISO3183 – L245/L290/L320/L360/L415/L485 etc. |

|

|

|

Minimum Order Quantity |

1 Ton |

|

||

|

Outside Diameter Ranges |

PSL-1 |

0.405-80(in) or 10.3mm-2032mm |

|

|

|

PSL-2 |

4 1/2 -80(in) or 114.3mm-2032mm |

|

||

|

Wall Thickness Ranges |

SCH10~SCH160 Or STD,XS,XXS Or 1.73mm~59.54mm |

|

||

|

Length |

For 20Ft Container |

4.8m-5.8m |

|

|

|

(negotiable) |

For 40Ft Container |

4.8m-12m |

|

|

|

|

Most common choice |

6m, 12m |

|

|

|

Type |

Welded |

ERW,LSAW/SSAW |

|

|

|

Seamless |

Cold Drawn,Hot Finished,Hot Expanded |

|

||

|

Cap (negotiable) |

Pipe size should under DN600 |

|

||

|

Pipe End |

Plain end |

All sizes |

|

|

|

Bevel end |

Pipe size above DN50, and the thickness should greater than 3.2mm |

|

||

|

Our advantages |

·Diverse products(Steel pipes, pipe fittings, other fittings) |

|

||

|

·Any third party inspection is accepted by we company. |

|

|||

|

·Quick response in quotation,delivery,after-service. |

|

|||

|

·Focus on pipe & tube solution for project application. |

|

|||

Epoxy Primer Coated Pipes Coating Specification

Epoxy Primer Coated Pipes Coating Specification

|

External Coating |

|

|

|

Coating type |

Coating Standard |

|

|

3LPE/3LPP |

DIN30670-1991,CAN/CSA Z245,21-2010,ISO21809-1-2009 SY/T 0413-2002,GB/T23257-2009 |

|

|

2LPE/2LPP |

SY/T 0315-2002,GB/T23257-2009,ISO21809-1-2009 |

|

|

FBE(Fusion-bond epoxy) |

SY/T 0315-2005,AWWA C213-2001,CAN/CSAZ245.20-2010,ISO218909-2-2007,API RP5L9-2001 |

|

|

Bitumen coating

Enamel &Tape hot-applied |

BS534-1990,AWWA203-2002,AWWA214-2000 |

|

|

Liquid epoxy coating |

AWWWA C210-2007 |

|

|

Polyurethane insulated coating |

SY/T0415-1996,CJ/T114-2000.EN253-1994 |

|

|

Internal Coating |

|

|

|

Liquid Epoxy Coating |

AWWAC210-2007 |

|

|

FBE |

AWWAC213-2001 |

|

|

Cement Mortar Lining |

BS534-1990,AWWA C205-2001 |

|

|

Bitumen Coating |

BS534-1990 |

|

Epoxy Primer Coated Pipes Technique Data

Epoxy Primer Coated Pipes Technique Data|

Technique Data |

|

|

Moisture Content: |

<0.5% |

|

Particle Size: |

Larger than 250um<0.2% Larger than 150um<3.0% |

|

Density: |

1.2~1.8g/cm3(Owing to the different formula and different colors) |

|

Recommened Film Thinkness : |

a. In FBE systems: 300-400 microns (12-16 mils) b. As a primer in 3-layer PE or PP systems: 150-300 microns (6-12 mils) |

|

Theoretical Coverage: |

0.6993 m2/kg per mm (134.6 ft2/lb per mil) |

|

Operating Temperature Range: |

"-73ºC (-100ºF) to 110ºC (230ºF) |

|

Storage Time: |

12 Months if stored below 27ºC (80ºF) and 65% relative humidity. |

|

On Sieve: |

150μm powder on sieve ≤3%,250μm powder on sieve ≤0.2% |

|

Gel time: |

under 200℃≥12s, and in accordance with manufacturer’s value ±20% |

|

Thermal properties |

ΔH≥45J/g,Tg2≥95℃ |

Our factory

Our factory

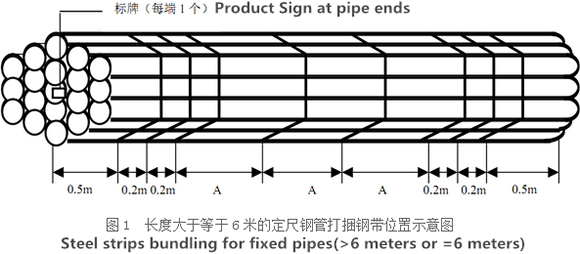

Packing

Packing

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.Our packing can meet any needs of the customers.

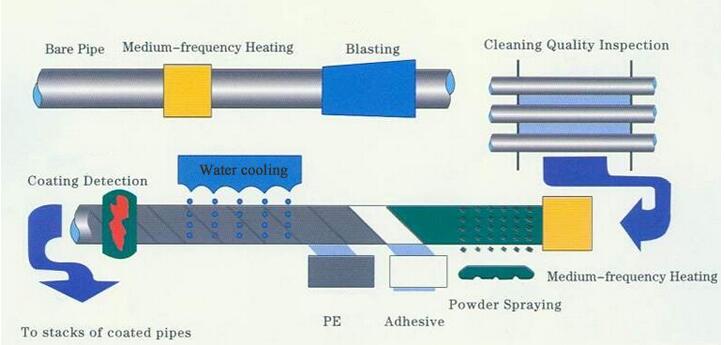

Manufacture Process

Manufacture Process

Equipment

Equipment

If you have any inquiries and questions, please contact United Steel Industry Co.,Ltd

at any time. Thanks in advance. Welcome! Email :Sales@united-steel.com