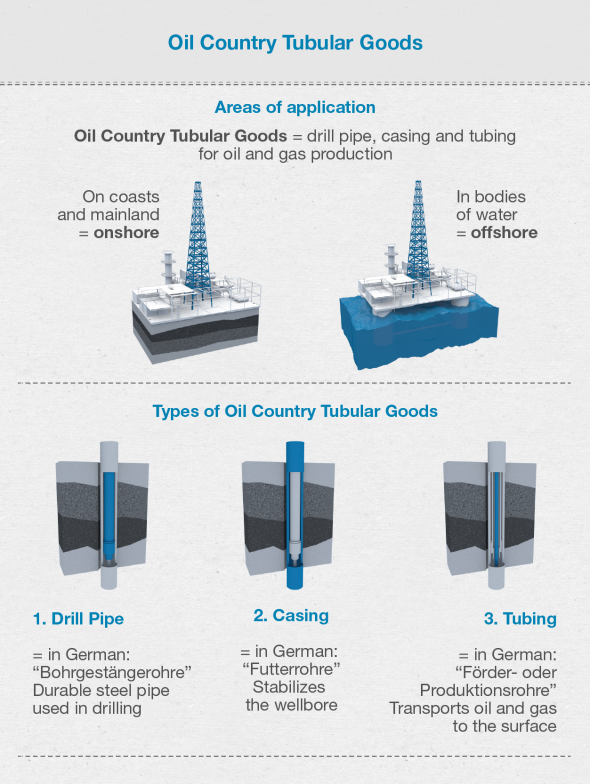

Oil country tubular goods (OCTG) is a family of seamless rolled products consisting of drill pipe, casing and tubing subjected to loading conditions according to their specific application.

Corrosion resistance under sour service conditions is a very important OCTG characteristic, especially for casing and tubing.

Standard and Grades: API 5CT J55 / K55, N80-1, N80Q, C90, T95, P110, Q125 and 13CrSunnySteel supplies API 5CT casing pipes with the following sizes and specifications:

Casing Pipe Size range: 5 1/2 “to 20” Length usually in R3.

Tubing Pipe dimensions range: 1.0 “, 1.315”, 1.66 “, 1.9”, 2.063 “, 2 3/8”, 3 1/2 “and 4 1 /2”, Length in R2.

Type of connections for Casing: BTC (thread coupling buttress), LTC (long round thread coupling), premium connection.

Types of connections for Tubing: BTC, NUE, EUE, Premium

Each wellbore proceeds in multiple phases, during which

The American Petroleum Institute (API) stipulates precisely standardized specifications that define the properties of Oil Country Tubular Goods and classify them into ten grades. These properties are achieved through the chemical composition of the steel and subsequent heat treatment.

Oil Country Tubular Goods are used both onshore and offshore. In the industry, they are also referred to by the acronym OCTG (for “Oil Country Tubular Goods”).

Typical OCTG manufacturing processes include (all dimensional ranges are approximate)

These processes typically do not allow the thermomechanical processing customary for the strip and plate products used for welded pipe. Therefore, high-strength seamless pipe must be produced by increasing the alloying content in combination with a suitable heat treatment such as quench & tempering.

Schematic deep well completion

Meeting the fundamental requirement of a fully martensitic microstructure even at large pipe wall thickness requires good hardenability. Cr and Mn are the main alloying elements used to produce good hardenability in conventional heat-treatable steel. However, the requirement for good sulphide stress cracking (SSC) resistance limits their use. Mn tends to segregate during continuous casting and can form large MnS inclusions that reduce hydrogen induced cracking (HIC) resistance.

OCTG includes threaded casing and tubing that are used in equipping and operating oil and gas wells.

Higher levels of Cr can lead to formation of Cr7C3 precipitates with coarse plate-shaped morphology, which act as hydrogen collectors and crack initiators. Alloying with Molybdenum can overcome the limitations of Mn and Cr alloying. Mo is a much stronger hardener than Mn and Cr, so it can easily recover the effect of a reduced amount of these elements.