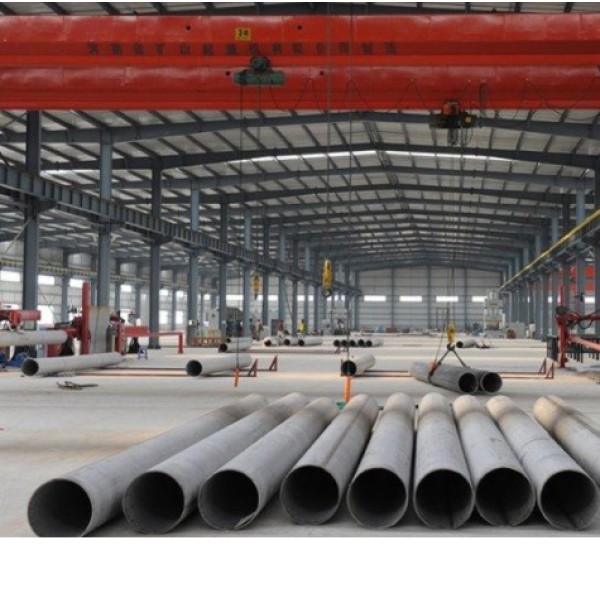

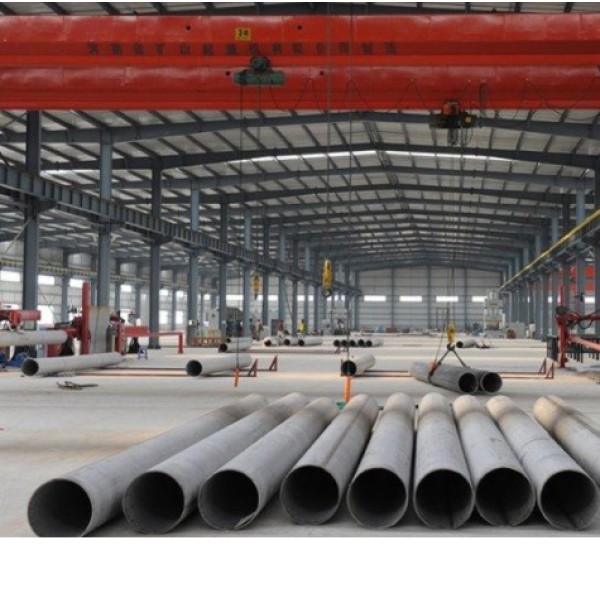

Stainless steel pipe is a kind of hollow long round steel, which is mainly used in industrial transportation pipelines and mechanical structural components such as petroleum, chemical industry, medical treatment, food, light industry, mechanical instrument and so on. In addition, when the bending and torsional strength are the same, the weight is lighter, so it is also widely used in the manufacture of mechanical parts and engineering structures. It is also commonly used to produce various conventional weapons, barrels, shells, etc.

Stainless steel pipes are divided into ordinary carbon steel pipes, high-quality carbon structural steel pipes, alloy structural pipes, alloy steel pipes, bearing steel pipes, stainless steel pipes and bimetallic composite pipes, plated and coated pipes for saving precious metals and meeting special requirements. . There are many kinds of stainless steel pipes, different uses, different technical requirements and different production methods. The outer diameter of the currently produced steel pipe ranges from 0.1 to 4500mm, and the wall thickness ranges from 0.01 to 250mm. In order to distinguish its characteristics, steel pipes are usually classified as follows.

production methods

Stainless steel pipes are divided into two categories: seamless pipes and welded pipes according to production methods. Seamless steel pipes can be divided into hot-rolled pipes, cold-rolled pipes, cold-drawn pipes and extruded pipes. Cold-drawn and cold-rolled pipes are the secondary Processing; welded pipes are divided into straight seam welded pipes and spiral welded pipes.

Cross-sectional shape

Stainless steel pipes can be divided into round pipes and special-shaped pipes according to the cross-sectional shape. Special-shaped tubes include rectangular tubes, diamond-shaped tubes, elliptical tubes, hexagonal tubes, octagonal tubes and various asymmetrical tubes. Special-shaped tubes are widely used in various structural parts, tools and mechanical parts. Compared with the round pipe, the special-shaped pipe generally has a larger moment of inertia and section modulus, and has a larger resistance to bending and torsion, which can greatly reduce the weight of the structure and save steel.

Stainless steel pipes can be divided into equal-section pipes and variable-section pipes according to the shape of the longitudinal section. Variable section tubes include tapered tubes, stepped tubes and periodic section tubes.

Pipe end shape

According to the state of the pipe end, the stainless steel pipe can be divided into a light pipe and a wire pipe (threaded steel pipe). The threading pipe can be divided into ordinary threading pipe (pipes for low-pressure transportation of water, gas, etc., which are connected by ordinary cylindrical or conical pipe threads) and special threaded pipes (pipes for petroleum and geological drilling. For important threading pipes, use Special threaded connection), for some special pipes, in order to make up for the influence of the thread on the strength of the pipe end, the pipe end is usually thickened (internal thickening, external thickening or internal and external thickening) before threading.

Classification of use

According to the purpose, it can be divided into oil well pipe (casing, oil pipe and drill pipe, etc.), line pipe, boiler pipe, mechanical structure pipe, hydraulic prop pipe, gas cylinder pipe, geological pipe, chemical pipe (high pressure fertilizer pipe, oil cracking pipe) ) and marine pipes, etc.

Wenzhou's stainless steel industry

Wenzhou's stainless steel industry is an emerging industry, which originated in the early 1980s. After 20 years of development and exploration, it has become well-known and influential in the domestic market.

At present, there are more than 130 production enterprises, which have a good momentum of development and expansion. There are 38 perforation equipments in the whole industry. There are more than 500 cold rolling and cold drawing equipments and 6 smelting equipments, all of which are refined outside the furnace, and other equipments are relatively complete. The production capacity and scale of enterprises are constantly expanding and enhancing. In 2001, there were 5 enterprises with an output value exceeding 100 million yuan, and more than 10 enterprises were rated as city and district star enterprises. In order to ensure product quality, analysis and testing equipment such as water pressure, eddy current and ultrasonic flaw detection, and direct reading spectrometers are constantly increasing and improving. In 2001, it was sampled and tested by the superior technical supervision department, and the pass rate was over 80%. There are more than 300 technical and management personnel with various middle and senior professional titles, and the company is gradually embarking on the track of standardized production and management. The stainless steel industry in Wenzhou mainly produces stainless steel pipes and rods, with more than 400 varieties, specifications and models. In 2001, the sales of stainless steel reached 1.715 billion yuan, and the output reached 106,000 tons. The stainless steel bar is 222 million yuan, the output is 211000 tons, and the national tax paid is more than 100 million yuan. The export volume of steel pipes has also increased year by year. In 2001, it was 5,000 tons. It is estimated that the export volume this year will be 8,000-10,000 tons. More than 10 enterprises have obtained self-support import and export rights. Stainless steel pipes are exported to dozens of countries and regions in Southeast Asia and the European Union, and are deeply appreciated by foreign merchants and users.

The stainless steel pipe industry was originally blank in Wenzhou. It has developed rapidly and its scale has continued to expand. However, there is still a certain gap in production capacity, which still cannot meet the needs of the domestic market. The future development ideas and specific practices of Wenzhou stainless steel industry are:

⒈ Focus on increasing product output, strengthen internal management of enterprises, improve the scale and grade of enterprises, further improve the popularity of Wenzhou stainless steel pipes and enterprises, encourage enterprises to develop into groups, and strengthen the introduction and training of technical personnel and management talents. Strengthen the construction of production equipment to ensure and improve product quality.

⒉ Towards the road of brand development, the number of Wenzhou stainless steel industry and the credit of entrepreneurs will shape Chinese brand awareness.

3. Establish a Wenzhou stainless steel pipe production park, gather stainless steel production enterprises, make the scale, the grade, the leader, the famous brand, and form a group production; through mergers, affiliations, equity participation, alliances, etc., to achieve the "Zhejiang Provincial Economic and Trade Department" key development goals.

⒋ Do a good job in the Wenzhou stainless steel professional market. The stainless steel industry is developing rapidly, but because there is no professional market of a certain scale, it cannot attract customers from all over the world, so production enterprises can only set up operations in various parts of the country, which not only increases the cost of enterprises, but also hinders the development of enterprises. If a professional market is built, which integrates production, sales and services, it will enable production enterprises to truly gain a foothold, go to the whole country, and rush out of the country.

This kind of steel pipe can be divided into two categories: stainless steel seamless steel pipe and stainless steel welded steel pipe (seamed pipe).

stainless steel pipe

There are several basic types: hot rolling, extrusion, cold drawing and cold rolling. According to the cross-sectional shape, they can be divided into round pipes and special-shaped pipes. Round pipes are widely used, but there are also some square, rectangular, semicircular pipes , Hexagon, equilateral triangle, octagon and other special-shaped stainless steel pipes.

For steel pipes under fluid pressure, hydraulic tests should be carried out to check their pressure resistance and quality. If there is no leakage, wetting or expansion under the specified pressure, it is qualified. Some steel pipes also need to be crimped according to standards or requirements of the buyer. , flaring test, flattening test.

Seamless stainless steel pipe, also known as stainless steel seamless pipe, is made of steel ingots or solid tube blanks through perforation to make capillaries, and then hot-rolled, cold-rolled or cold-drawn. The specifications of seamless steel pipes are expressed in millimeters of outer diameter * wall thickness.

201 stainless steel pipe--S20100 (AISI.ASTM)

The full name of 304 stainless steel pipe is SUS304 stainless steel pipe

SUS304 stainless steel pipe belongs to the stainless steel pipe of American grade material. The domestic grade is equivalent to 0Cr19Ni9 stainless steel pipe, which is usually replaced by 0Cr18Ni9.

The mechanism of stainless steel rust prevention is that the alloying elements form a positive potential and no longer have the ability to transport electrons to the oxidant.

The rust phenomenon of 304 material may have the following reasons:

⒈ Chloride ions exist in the use environment.

Chloride ions exist widely, such as salt, sweat, seawater, sea breeze, soil and so on. In the presence of chloride ions, stainless steel corrodes very quickly, even more than ordinary low carbon steel. Chloride ions form complexes with Fe in alloying elements, reducing the positive potential of Fe, and then being oxidized by oxidant deprivation of electrons.

Therefore, there are requirements for the use environment of stainless steel, and it needs to be wiped frequently to remove dust and keep it clean and dry.

316 and 317 stainless steels are molybdenum-containing stainless steels. The molybdenum content in 317 stainless steel is slightly higher than that in 316 stainless steel. Due to the molybdenum content in 316 stainless steel, the overall performance of this steel is better than that of 310 and 304 stainless steel. Under high temperature conditions, when the concentration of sulfuric acid is lower than 15% and higher than 85% , 316 stainless steel has a wide range of uses. 316 stainless steel also has good resistance to chloride attack, so it is usually used in marine environments.

With the development of society and economy, the application of stainless steel pipe has been more and more widely popularized. It will definitely bring new changes in various fields.

The theoretical weight formula of stainless steel pipe: W = (outer diameter - wall thickness) x wall thickness x 0.02491 x length, where the unit of W is kg, the unit of outer diameter and wall thickness is mm, and the unit of length is meter (m).

Production Process

Production process of stainless steel welded pipe:

Raw material--slitting--welding pipe--repairing--polishing--inspection (printing)--packaging--shipping (warehousing) (decorative welded pipe)

Raw material--slitting--welding pipe--heat treatment--correction--straightening--end trimming--pickling--water pressure test--inspection (printing)-packaging--shipping (warehousing) (Pipe for welded pipe industrial piping)

Hardness

Stainless steel pipes are generally measured by three hardness indicators: Brinell, Rockwell and Vickers.

Brinell hardness

Among the stainless steel pipe standards, the Brinell hardness is the most widely used, and the hardness of the material is often expressed by the indentation diameter, which is both intuitive and convenient. However, it is not suitable for steel pipes of harder or thinner steel.

Rockwell hardness

The Rockwell hardness test of stainless steel pipe is the same as the Brinell hardness test, which is an indentation test method. The difference is that it measures the depth of the indentation. Rockwell hardness test is a widely used method, among which HRC is second only to Brinell hardness HB in steel pipe standards. Rockwell hardness can be used to measure metal materials from extremely soft to extremely hard. It makes up for the inadequacy of the Brinell method. It is simpler than the Brinell method and can directly read the hardness value from the dial of the hardness machine. However, due to its small indentation, the hardness value is not as accurate as the Brinell method.

Vickers hardness

The Vickers hardness test of stainless steel pipe is also an indentation test method, which can be used to measure the hardness of very thin metal materials and surface layers. It has the main advantages of Brinell and Rockwell methods, and overcomes their basic shortcomings, but it is not as simple as the Rockwell method, and the Vickers method is rarely used in steel pipe standards.

Hardness testing

For annealed stainless steel pipes with an inner diameter of more than 6.0mm and a wall thickness of less than 13mm, the W-B75 Webster hardness tester can be used. For stainless steel pipes with an inner diameter greater than 30mm and a wall thickness greater than 1.2mm, use a Rockwell hardness tester to test HRB and HRC hardness. The inner diameter of the stainless steel tube is greater than 30mm and the wall thickness is less than 1.2mm. The surface Rockwell hardness tester is used to test the HRT or HRN hardness. For stainless steel pipes with an inner diameter of less than 0mm and greater than 4.8mm, use a Rockwell hardness tester for pipes to test HR15T hardness. When the inner diameter of the stainless steel pipe is greater than 26mm, the hardness of the inner wall of the pipe can also be tested with a Rockwell or surface Rockwell hardness tester.