WHAT IS A106 PIPES

A106 Pipe is the black carbon steel pipe, A106 Gr B Sch 40, A106 Gr B Erw Pipe and ASTM A106 Seamless Pipe for high-temperature and high-pressure service. ASTM/ASME A-106/SA-106 grade seamless pipes are one of our most widely used grade of carbon steel and are readily available ex-stock for all standard thicknesses up to SCH160. These A106 Seamless Pipes, SA106 Pipe, ASTM A106 Grade B Line pipe are available in three grades A, B, and C of varying strength. NPS 1-1/2 and under may be either A106 grade b hot finished or A106 grade b cold drawn. NPS 2 and larger shall be A106 grade b hot finished unless otherwise specified. Surface finish standards are outlined in the specification. SA106 Material, ASTM A106 Grades A and ASTM A106 B are obtainable in most sizes and schedule numbers, SA106 Grade B permits higher carbon and manganese contents than Grade A. The A106 Grade B Pipe, ASTM A106 Grade B Schedule 40 Pipe and A106 Black Pipe supplied by ASTM Seamless Pipes has a maximum carbon content of 0.23%.

ASTM A106 Grade B specification covers a carbon steel pipe for high-temperature service. These ASTM A106 Grade B Pipe are reasonable for welding, bending, flanging, and similar forming operations. Mechanical testing of the specimens shall include tensile, bending, flattening, hydrostatic and nondestructive electric tests. Specimens undergoing bending tests shall consist of the area cut from a pipe. For flattening tests, the specimens shall be smooth on the ends and burr-free, with the exception of when made on crop ends. SA106 Welded pipes are normally more readily available than SA106 seamless pipe. The longer lead time required for carbon steel astm a106 pipe, ASTM A106 Gr.B Seamless Pipe can not only make timing problematic, but it also allows more time for the price of the materials to fluctuate.

ASTM A106/ASME SA106 is the standard specification for seamless carbon steel pipe used for high-temperature services. It includes three grades: A, B, and C, with Grade B being commonly used. This type of pipe finds applications in various industries, including pipeline systems for oil and gas, water, and mineral slurry transmission. It is also used in boiler systems and for construction and structural purposes.

ASTM A106 Grade B pipe is considered equivalent to ASTM A53 Grade B and API 5L Grade B in terms of chemical composition and mechanical properties. It is a type of carbon steel that has a minimum yield strength of 240 MPa and a minimum tensile strength of 415 MPa.

Below, we will explain ASTM A106 Grade B pipe from different aspects:

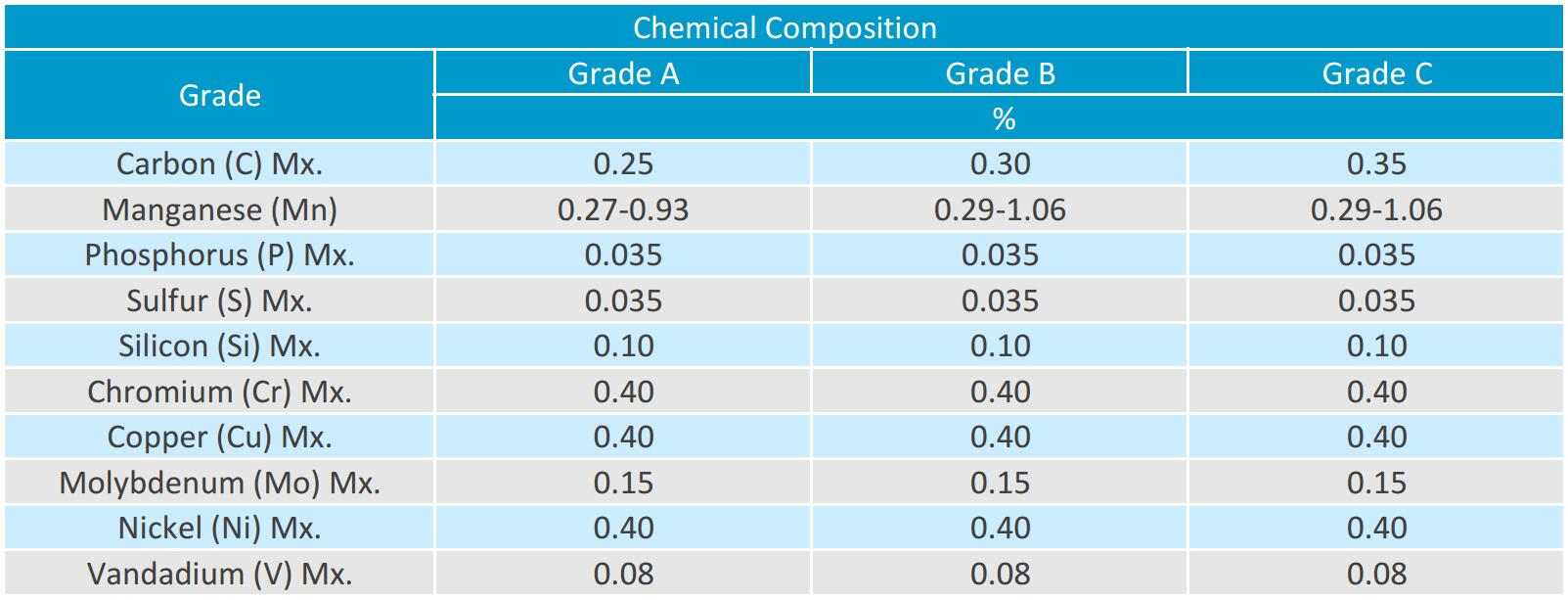

ASTM A106 Grade B and A pipe chemical composition

WHAT IS A106 PIPES

A106 Pipe is the black carbon steel pipe, A106 Gr B Sch 40, A106 Gr B Erw Pipe and ASTM A106 Seamless Pipe for high-temperature and high-pressure service. ASTM/ASME A-106/SA-106 grade seamless pipes are one of our most widely used grade of carbon steel and are readily available ex-stock for all standard thicknesses up to SCH160. These A106 Seamless Pipes, SA106 Pipe, ASTM A106 Grade B Line pipe are available in three grades A, B, and C of varying strength. NPS 1-1/2 and under may be either A106 grade b hot finished or A106 grade b cold drawn. NPS 2 and larger shall be A106 grade b hot finished unless otherwise specified. Surface finish standards are outlined in the specification. SA106 Material, ASTM A106 Grades A and ASTM A106 B are obtainable in most sizes and schedule numbers, SA106 Grade B permits higher carbon and manganese contents than Grade A. The A106 Grade B Pipe, ASTM A106 Grade B Schedule 40 Pipe and A106 Black Pipe supplied by ASTM Seamless Pipes has a maximum carbon content of 0.23%.

ASTM A106 Grade B specification covers a carbon steel pipe for high-temperature service. These ASTM A106 Grade B Pipe are reasonable for welding, bending, flanging, and similar forming operations. Mechanical testing of the specimens shall include tensile, bending, flattening, hydrostatic and nondestructive electric tests. Specimens undergoing bending tests shall consist of the area cut from a pipe. For flattening tests, the specimens shall be smooth on the ends and burr-free, with the exception of when made on crop ends. SA106 Welded pipes are normally more readily available than SA106 seamless pipe. The longer lead time required for carbon steel astm a106 pipe, ASTM A106 Gr.B Seamless Pipe can not only make timing problematic, but it also allows more time for the price of the materials to fluctuate.

ASTM A106/ASME SA106 is the standard specification for seamless carbon steel pipe used for high-temperature services. It includes three grades: A, B, and C, with Grade B being commonly used. This type of pipe finds applications in various industries, including pipeline systems for oil and gas, water, and mineral slurry transmission. It is also used in boiler systems and for construction and structural purposes.

ASTM A106 Grade B pipe is considered equivalent to ASTM A53 Grade B and API 5L Grade B in terms of chemical composition and mechanical properties. It is a type of carbon steel that has a minimum yield strength of 240 MPa and a minimum tensile strength of 415 MPa.

Below, we will explain ASTM A106 Grade B pipe from different aspects:

ASTM A106 Grade B and A pipe chemical composition

Chemical composition in %

Carbon (C) Max For Grade A 0.25, For Grade B 0.30, Grade C 0.35

Manganese (Mn): 0.27-0.93, 0.29-1.06

Sulfur (S) Max: ≤ 0.035

Phosphorus (P) : ≤ 0.035

Silicon (Si) Min : ≥0.10

Chrome (Cr): ≤ 0.40

Copper (Cu): ≤ 0.40

Molybdenum (Mo): ≤ 0.15

Nickel (Ni): ≤ 0.40

Vanadium (V): ≤ 0.08

Please note:

For every reduction of 0.01% in the maximum carbon element, an increase of 0.06% in manganese above the specified value is allowed, up to a maximum of 1.35%.

Elements Cr, Cu, Mo, Ni, V combined shall not exceed 1%.

Elongation formula:

In 2 in. [50mm], shall be calculated by: e = 625 000 A^0.2 / U^0.9

For inch-pound Units, e = 1940 A^0.2 / U^0.9

Explanations of e, A, and U, please find here. (Equation same with ASTM A53, API 5L pipe.)

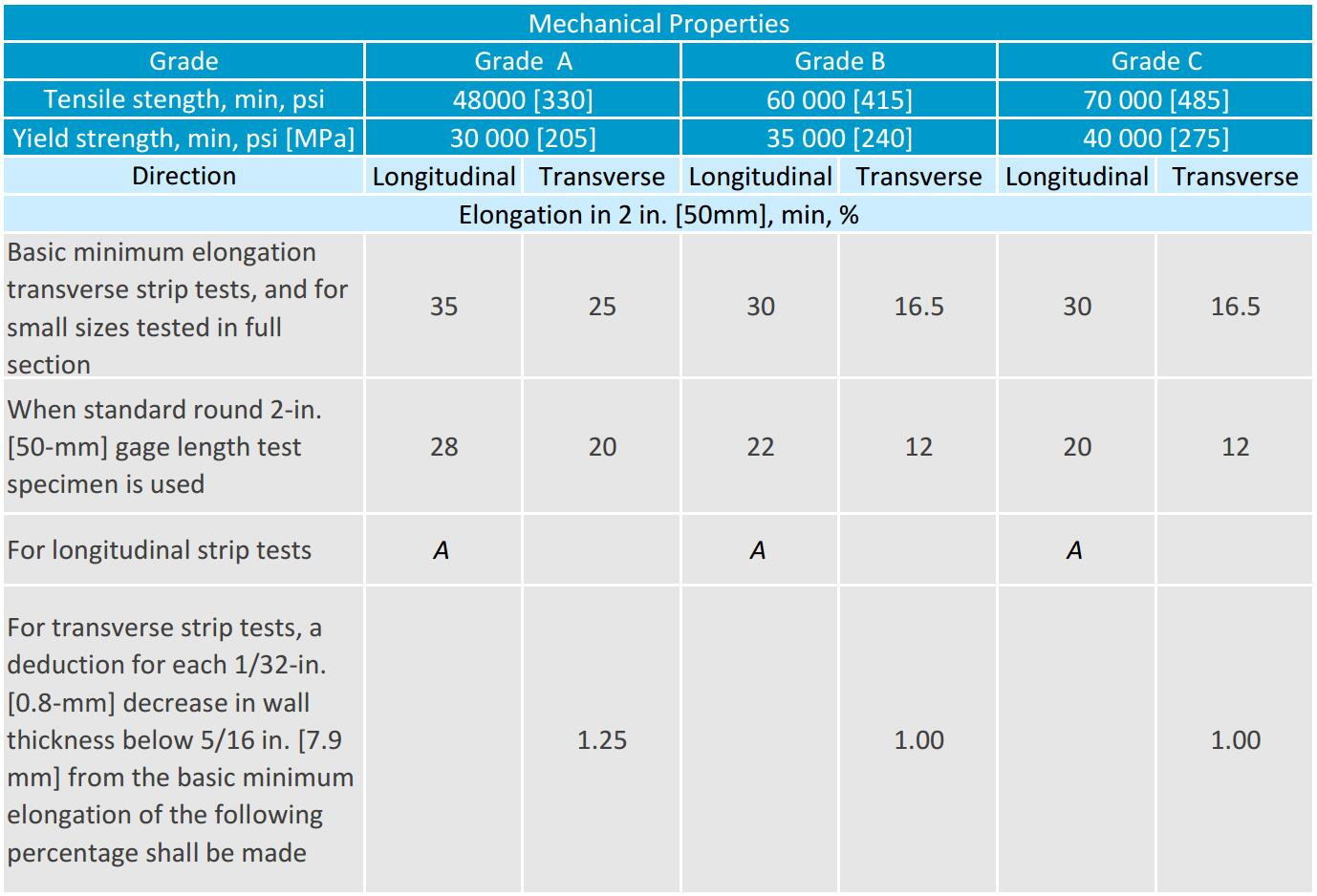

Tensile Strength, min, psi [MPa] Grade A 48,000 [330], Grade B 60,000 [415], Grade C 70,000 [485]

Yield Strength minimum at psi [MPa] Grade A 30,000 [205], B 35,000 [240], C 40,000 [275]

Elongation in 2 in (50mm), minimum percentage % ,

For all small sizes tested in full section, basic minimum elongation transverse trip tests: Grade A Longitudinal 35, Transverse 25; B 30, 16.5; C 30, 16.5;

In case standard round 2 inch gage length test sample is used, above values are: Grade A 28, 20; B 22, 12; C 20, 12.

Chemical composition in %

Carbon (C) Max For Grade A 0.25, For Grade B 0.30, Grade C 0.35

Manganese (Mn): 0.27-0.93, 0.29-1.06

Sulfur (S) Max: ≤ 0.035

Phosphorus (P) : ≤ 0.035

Silicon (Si) Min : ≥0.10

Chrome (Cr): ≤ 0.40

Copper (Cu): ≤ 0.40

Molybdenum (Mo): ≤ 0.15

Nickel (Ni): ≤ 0.40

Vanadium (V): ≤ 0.08

Please note:

For every reduction of 0.01% in the maximum carbon element, an increase of 0.06% in manganese above the specified value is allowed, up to a maximum of 1.35%.

Elements Cr, Cu, Mo, Ni, V combined shall not exceed 1%.

ASTM A106 Grade B Tensile Strength and Yield Strength

Elongation formula:

In 2 in. [50mm], shall be calculated by: e = 625 000 A^0.2 / U^0.9

For inch-pound Units, e = 1940 A^0.2 / U^0.9

Explanations of e, A, and U, please find here. (Equation same with ASTM A53, API 5L pipe.)

Tensile Strength, min, psi [MPa] Grade A 48,000 [330], Grade B 60,000 [415], Grade C 70,000 [485]

Yield Strength minimum at psi [MPa] Grade A 30,000 [205], B 35,000 [240], C 40,000 [275]

Elongation in 2 in (50mm), minimum percentage % ,

For all small sizes tested in full section, basic minimum elongation transverse trip tests: Grade A Longitudinal 35, Transverse 25; B 30, 16.5; C 30, 16.5;

In case standard round 2 inch gage length test sample is used, above values are: Grade A 28, 20; B 22, 12; C 20, 12.