-

JIS G 4053 SNCM 439 Seamless Steel Pipes

Standard : JIS G 4053

Equivalent material: 40CrNiMoA , 4340 , 817M40 ,816M40

Delivery condition : By heat treatment (normalizing, annealing and high temperature tempering) or heat treatment state delivery, delivery status should be indicated in the contract

-

As a professional supplier of St52.8 Seamless pipes, DMH United Steel Industry will offer St52.8 Seamless Tubes price and St52.8 Seamless Tubes machining service. Our DIN 17175 St52.8 seamless pipes and tubes are used in boiler installations, high-pressure pipelines and tank construction and special machinery for both high temperature and high-pressure devices.

-

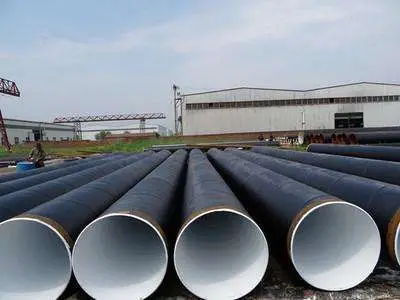

Drinking water pipe with anti-corrosion spiral steel pipe technology

-

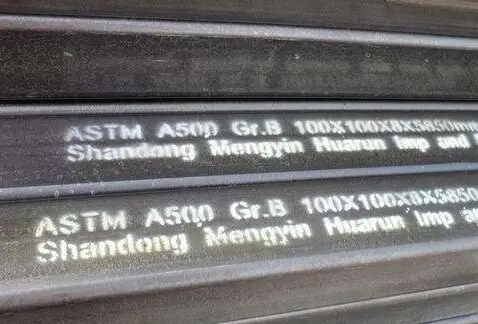

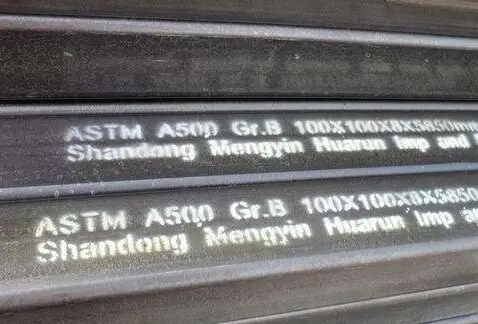

ASTM A500/ A501 is a standard specification for cold-formed welded and seamless carbon steel structural tubing in round, square and rectangular shapes.

-

Epoxy coal tar pitch pipe corrosion (three cloth two oil pipe corrosion): Epoxy resin + coal tar pitch + filler made of paint in the steel exterior with glass cloth as a coating made of reinforced coating, the thickness of 0.5 ~ 1.0mm . According to customer-made three cloth two oil four cloth two oil. Epoxy coal tar pitch pipe corrosion (three cloth two oil pipe corrosion) Features: Tough tough fullness, strong adhesion Has excellent chemical resistance Corrosion resistance, excellent water resistance, anti-microbial corrosion Epoxy coal tar primer and epoxy Two types of coal tar finish. The company's epoxy coal tar pitch primer for the solvent-based products; epoxy coal tar topcoats for the series of products, according to the solid content is divided into solvent-free type (GH201) and thick type (GH202) two types, according to the coating The heat-resistant temperature is divided into temperature-resistant type (at 150 ℃, filling W) and standard (used at 100 ℃), for users according to the anti-corrosion engineering practice requirements.

-

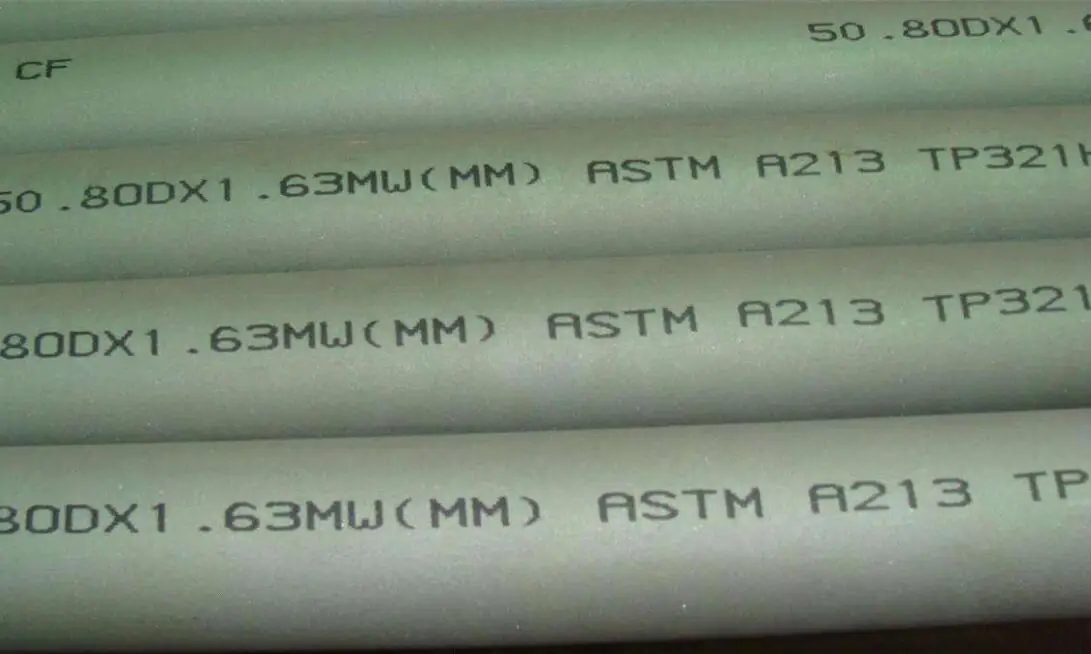

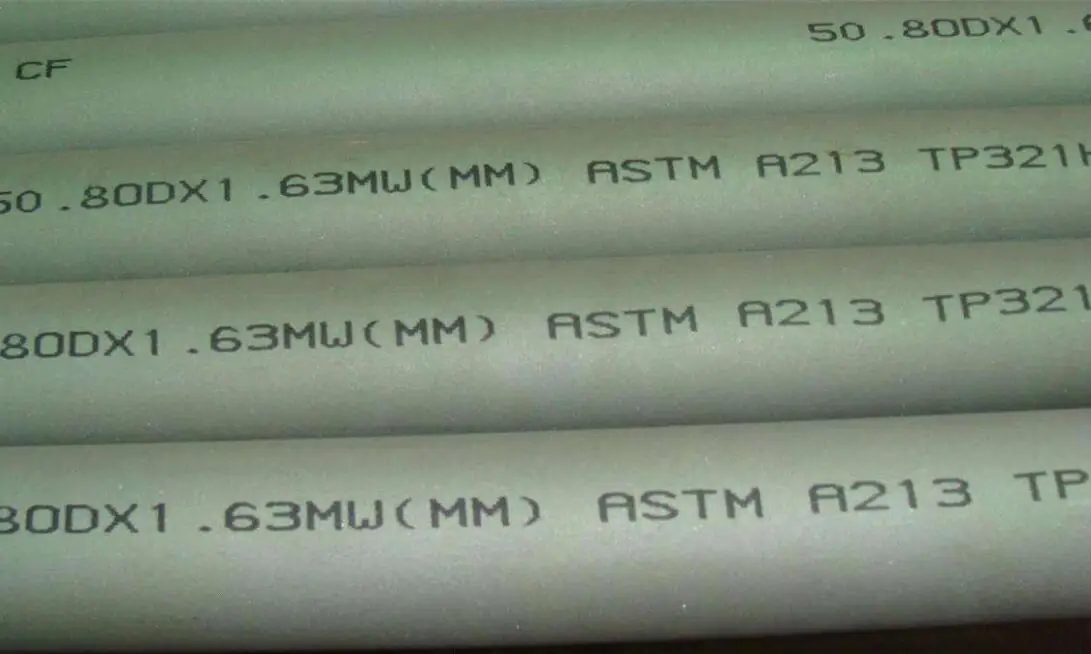

ASTM A213__for seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes

-

ASTM A210__for seamless medium-carbon steel boiler and superheater tubes

Delivery Condition: Annealed, Normalized, Normalized and Tempered

Surface treatment: Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting

Application: For high, middle, low pressure boiler and pressure purpose

-

DMH UNITED STEEL INDUSTRY is a leader in seamless pipe for petroleum casing, oil pipeline, structural seamless pipe and fluid in China and has won many honors over the years.

Insulation layer of oil casing selection of aluminum silicate centrifugal cotton composite material (also can choose other insulation materials), thermal insulation effect is good. Oil casing vacuum technology can be used to eliminate the outer wall of the coat pipe electrochemical corrosion caused by moisture, while further enhancing the insulation effect of the pipeline.

-

Dmh United de acero a lo largo de los años, proporcionando a los clientes la calidad de aceite de petróleo, tubos y estructura de tubos de acero sin soldadura, fluido de tubos de acero sin soldadura, productos de alta calidad y bajo precio, bienvenido a los clientes de la compra.

Cubierta de petróleo

-

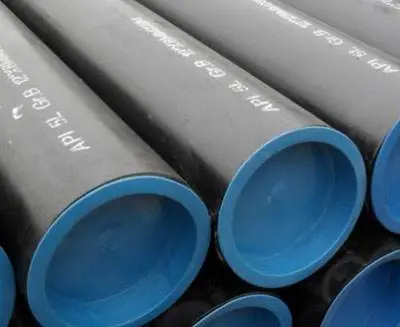

API 5L/A53 GR.B, ERW Steel Pipe

-

ASTM A178 is for electric-resistance-welded carbon steel and carbon-manganese steel boiler and superheater tubes

-

Manufacture of Hot-Dip Zinc Coating Fasteners according to ASTM A153 / ASTM A153M

ASTM A153 / A153M - 09 Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware

-

ASTM A53 contains seamless steel pipe and welded steel pipe black and hot-dipped galvanized steel pipe in NPS 1/8 to NPS 26. The steel categorized in this standard must be open-hearth, basic-oxygen or electric-furnace processed and must have the following chemical requirements: carbon, manganese, phosphorus, sulfur, copper, nickel, chromium, molybdenum, and vanadium. The tubing shall undergo a seamless or welding process. Tension, bend, and flattening tests shall be performed to make sure that it must adhere to the mechanical properties of the standard.

-

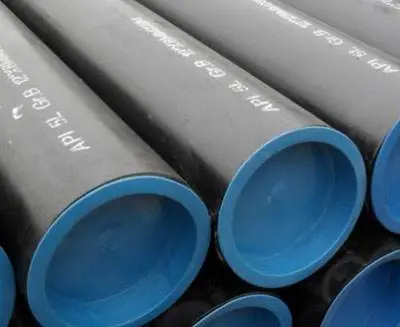

API 5L is a standard of API 5L line pipe. Specifications for API 5L adhere to the International Organization for Standardization ISO 3183. The API 5L specification provides standards for pipe suitable for use in conveying gas, water, and oil in the natural gas and oil industries. The API SPEC 5L covers seamless and welded steel line pipe. It includes standard-weight and extra-strong threaded line pipe; and standard-weight plain-end, regular-weight plain-end, special plain-end, extra-strong plain-end, special plain-end, extra-strong plain-end pipe, as as well as bell and spigot and through-the-flow line(TFL) pipe.

-

Through these two years, the steel pipe industry, the cumulative market price rose as much as 1,500-2800 yuan / ton, from 2000-3000 yuan / ton before 2016, violently rose to 4000-6000 yuan / ton, one can imagine the speed Still amazing. However, the high level of the industry did not continue to open. The downturn of the real estate industry and the retrenchment of investment in infrastructure construction and the cautious macroeconomic stimulation all inhibited the progress of the steel pipe to a certain extent. For 2018, to maintain the high level of 2017 is already a success. If we want to brush the record again, we will not only need to make changes in our own industries but will also need the impetus from the external environment.

-

With the continuous structural reform of the supply side, the steel industry related metal products industry, including the steel pipe industry, has been brewing a good trend recently, but the real turning point of the relevant industries has not yet come. According to statistics, after nearly a decade of development, China's steel pipe industry has been continuously optimized and upgraded in terms of product structure, quality level, technical equipment and so on. It has become a veritable world steel pipe manufacturing powerhouse and is now making its stride in the world's steel pipe industry. However, the staged contradictions and structural contradictions in the development of China's steel pipe industry have emerged as a "bottleneck" that hinders the sustainable, healthy and stable development of the steel pipe industry. The depth adjustment of the steel pipe industry is still under way.

-

Main Reasons Those Affect The Quality of Pipe Bend

-

welded steel pipe,ERW steel pipe,SSAW steel pipe,LSAW steel pipe

-

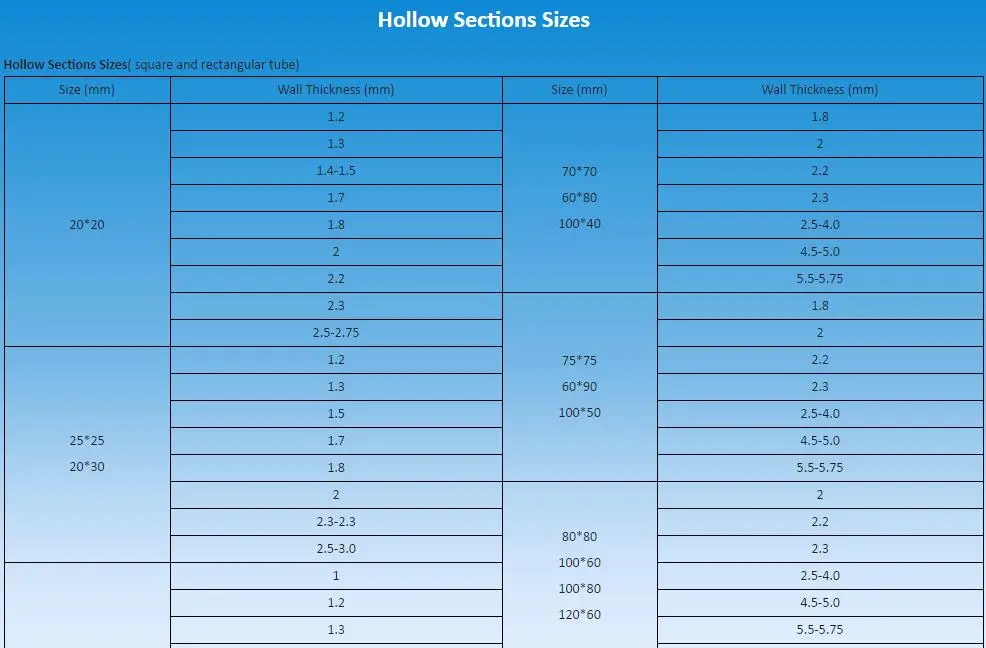

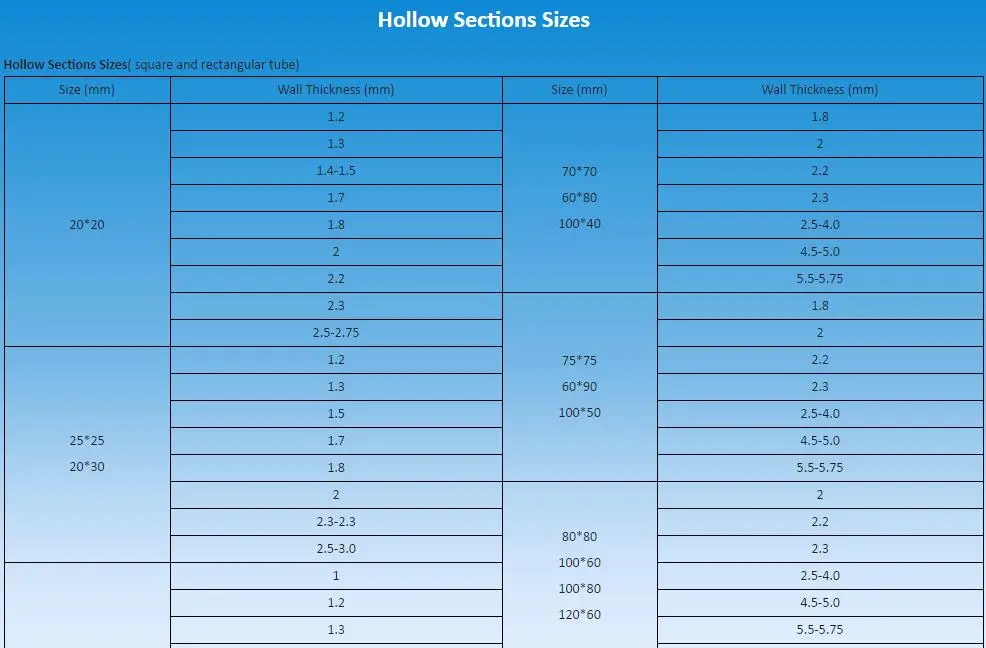

Hollow Sections Sizes( square and rectangular tube)

-

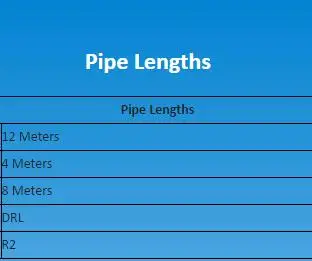

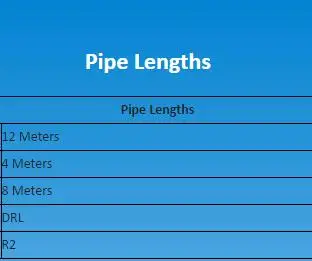

Steel Pipe Lengths

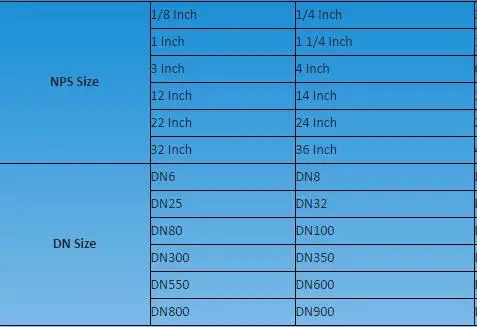

-

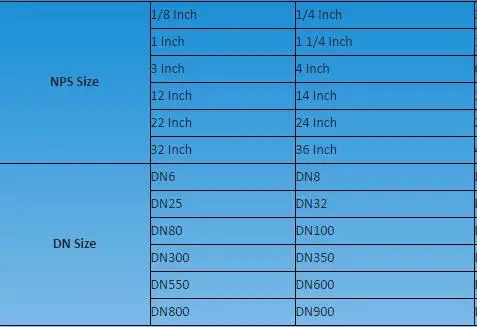

Steel Pipe Size