-

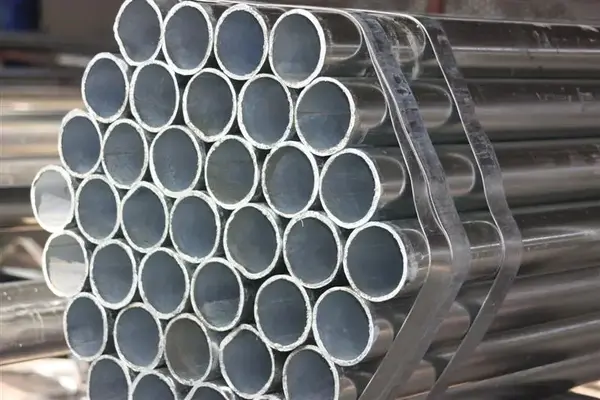

When stacking galvanized steel pipes, we must do a reasonable stacking and advanced first-hand

-

Difference between cold galvanizing and hot galvanizing

-

In recent years, many applications of hot rolled coils, especially thin gauge products, in the automotive industry, construction occupation, compressor occupation, etc.

-

The raw material of cold-formed steel is hot-rolled coil, and most of the coils used for cold-formed steel have no thickened plates at all.

-

Hot rolled coil products have excellent functions such as high strength, good resistance, easy processing and excellent weldability. They are widely used in cold rolled substrates, ships, cars, bridges, construction, machinery, oil pipelines, pressure vessels. Waiting for a production career.

-

The market volume of large-diameter seamless steel pipe has decreased compared with the previous period, and the turnover of rolled billet enterprises has also been stopped. The demand for billet market is not large, so the price is difficult to continue to rise.

-

The output of crude steel increased slightly for two consecutive months. The contradiction between supply and demand of thick-walled seamless steel pipe market was prominent, and the price of steel fell. Steel prices rebounded slightly in October, but due to the overall supply and demand situation, steel prices will show a small dynamic trend in the later period.

-

The market for thick-walled seamless steel pipes is difficult to change, prices in many regions are generally lowered, and the willingness of downstream steel mills to purchase is still low. The main body of the domestically produced mineral market was stable this week, and the stalemate between supply and demand was highlighted.

-

The demand of the downstream industry is slowing down, and the competition in the large-diameter seamless steel pipe market will become more intense. However, the problems of tight capital, difficult financing, and expensive financing will be difficult to alleviate, and the risks of exchange rate and debt may increase.

-

The current market price has been at a low price for the same period in the past 10 years, and the market has a smaller breakthrough space.

-

There are relatively few orders for greenhouse traders. Although there are not many stocks in steel mills, the willingness to lower them is also obvious, thus promoting volume. In East China, the inventory in this week has increased slightly.

-

Steel mills: Puyang, Wenfeng and other second-tier steel mills, the plate price of 16-25mm plate is temporarily stable, although there is still room for discounted price orders, hot-dip galvanized greenhouse pipe merchants still have no order enthusiasm.

-

Due to the weak demand of the agents for the later period, the enthusiasm for ordering is lower. Although the market has a variety of out-of-stocks, the steel traders are very cautious in receiving the goods. This phenomenon once again shows that the merchants believe that the current steel market lacks price-driven power and is low.

-

It is expected that the mainstream trend today will still show a downward adjustment in the construction of the plate. Although the iron ore price is currently running weakly, the attention of the public is still very high, and how it will be interpreted in the future.

-

At present, there are fewer cold-rolled resources on the market. Although there are a small amount of resources to supplement the market one after another, overall, the resources available for circulation in the market are still limited.

-

Stainless steel Seamless pipe production companies are aware that the so-called stainless steel seamless pipe and carbon steel seamless pipe differences, mainly refers to the difference between the stainless steel and carbon steel planning rules, that is to say, the two kinds of steel planning rules can not be universal. The differences are as follows:

-

Carbon steel seamless pipe is a kind of steel strip. The pipe has a hollow section, a large number of pipelines used for conveying fluids, such as oil, gas, gas, water and some solid materials, such as pipelines.

-

(1) The importance of the structure of heavy industrial structures, large-span structures, high-rise or super-high-rise civil construction structures or structures and other important structures, should consider the selection of good quality seamless steel tubes, the general industrial and civil architecture, according to the nature of the work can be selected by the ordinary quality of seamless steel tubes.

-

The standard provisions in piping, mechanical properties, physical properties, the use of performance and process performance indicators, corresponding to the different steel grades. Performance metrics vary greatly. Mechanical properties: Tensile strength, yield intensity, elongation, hardness, impact energy; physical properties mainly refer to the grain size.

-

Hot dip galvanized square tube is used square tube plate or strip after curl forming in the hot dip galvanized pool through a series of chemical reactions forming the square tube; can also be hot-rolled or cold rolled galvanized steel strip after colda hollow square cross-section bend, then the high-frequency welded steel pipe.

-

This problem about flat welding flanges has always been a topic of concern. It is related to the production costs or economic benefits of companies and enterprises. Therefore, the sealing principle of flat welding flanges is constantly improving and perfecting.