-

What are the methods for calculating the parts of small-diameter seamless steel pipes ?

(1) Primary production process of hot rolled seamless steel pipe (delta initial inspection process):

Billet piercing and rolling heating preparation and inspection steel pipe sizing (reduction) heat treatment straightening finished pipe finishing inspection library

-

(1) Chongqing galvanized pipe , the pure zinc layer is densely covered on the surface of the steel, which can avoid any corrosion solution contacting the steel substrate and protect the corrosion of the steel substrate. In the general atmosphere, a zinc layer is formed on the surface of a thin layer of dense zinc oxide layer, which is hardly soluble in water, so the protection of the steel substrate. If other components of zinc oxide and the atmosphere form insoluble zinc salts, then the anti-corrosion effect is more ideal.

-

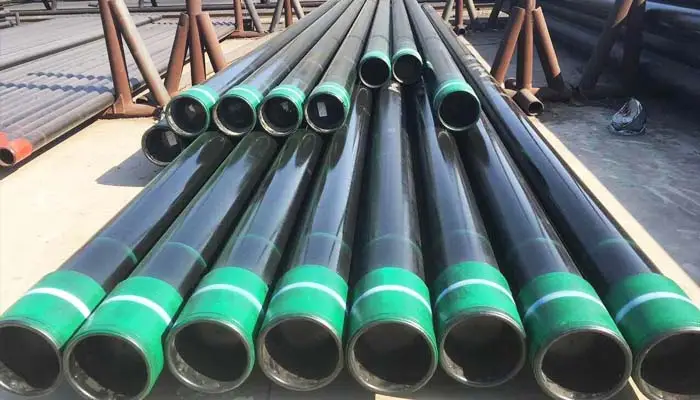

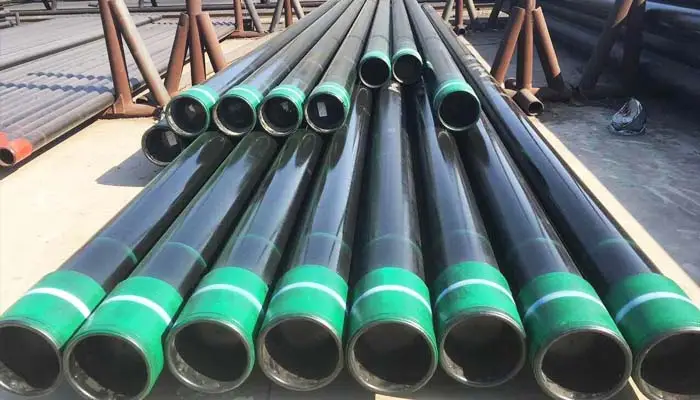

The invention provides a protective coating for oil pipes and wellheads and downhole equipment used in oil and gas drilling, oil recovery and transportation. The protective coating comprises, by weight percentage, 55 to 95% of polyphenylene sulfide, 3 to 30% of adhesion enhancer, and 1 to 20% of abrasion resistant enhancer. A surface wettability converting agent may also be included in the range of 1 to 15%. It can prevent or reduce the high temperature, high pressure, high hydrogen sulfide and carbon dioxide, high salt content and other strong corrosive media on the erosion, corrosion and waxing, scaling and hydrate blockage, reduce friction and reduce production costs. Improve the overall performance and service life of oil pipes. The present invention also provides a method of preparing such a protective coating and a method of constructing the same.

-

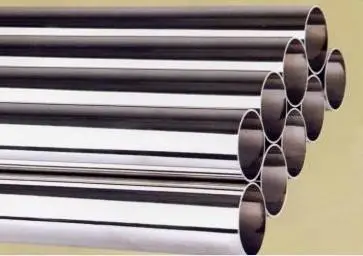

An ISO 9001:2008 certified company, Victor Steel supplies a wide range of ASTM A312 TP 316L Stainless Steel Seamless Pipe to customers across world.Our focus is on providing customers with high end steels that are not rolled or stocked locally.We are leading ASTM A312 TP 316L Stainless Steel Seamless Pipe manufacturer in Mumbai, Maharashtra

Grade 316L, the low carbon version of 316 and is immune from sensitisation (grain boundary carbide precipitation). Thus it is extensively used in heavy gauge welded components (over about 6mm). There is commonly no appreciable price difference between 316 and 316L stainless steel.victor Steel is leading ASTM A312 TP 316L Stainless Steel Seamless Pipe manufacturers in rajkot, Gujarat

316L stainless steel tends to work harden if machined too quickly. For this reason low speeds and constant feed rates are recommended.316L stainless steel is also easier to machine compared to 316 stainless steel due its lower carbon content.

-

1. Introduction to seamless steel pipe

The seamless steel pipe is a circular, square, rectangular steel with a hollow section and no seams around it. The seamless steel pipe is formed by perforating a steel ingot or a solid tube blank, and then hot rolled, cold rolled or cold drawn. The seamless steel pipe has a hollow section and is used as a pipe for conveying fluid. Compared with a solid steel such as round steel, the steel pipe has a lighter weight when it has the same bending and torsional strength, and is an economical section steel which is widely used for manufacturing structures. Parts and mechanical parts, such as steel scaffolding for oil drills.

-

Properties of Galvanized Steel Pipe Welds

Galvanizing has been used to protect iron and steel from rusting for over a hundred years in places as diverse as the wire rope used for the suspension cables on the Brooklyn Bridge to gutters on houses. Galvanizing is simply coating of zinc over steel. Like paint, galvanizing protects steel from rusting by forming a barrier between the steel and the environment, but galvanizing goes one giant step further than paint — it also provides electrochemical protection of the steel. Since zinc is electrochemically more reactive than steel, it oxidizes to protect the steel near it; as a result, even if a galvanized steel surface is scratched down to the bare steel, the galvanizing coating will prevent the steel from rusting. Galvanized steel is, therefore, a superior product to steel with any other type of coating on it since it protects the steel even when the coating is damaged in handling or in service.

-

The corrosion resistances of enamel-coated steel pipe in 3.5 wt% NaCl solution was evaluated and compared with those of epoxy-coated pipe using open-circuit potential, linear po- larization resistance, and electrochemical impedance spectros- copy tests. T-001c enamel slurry and GP2118 enamel powder were sprayed to steel pipe in wet and electrostatic processes, respectively. The phase composition and microstructures of the two enamels were characterized with x-ray diffraction and scanning electron microscopy (SEM). The surface roughness of enamels and their bond strength with steel substrates were quantified to understand coating quality. SEM images revealed that both types of enamel coatings have a solid structure with isolated bubbles. Electrochemical tests showed a high corrosion resistance of the enamel coatings as verified in visual inspection on the tested samples. In particular, the GP2118 enamel-coated samples consistently outperformed the epoxy-coated samples.

-

Stainless steel welded pipe needs to be protected by nitrogen when welding. What is the principle of nitrogen-protected stainless steel welded pipe ?

-

Stainless steel welded pipes will have some defects in the welding process. The defects of stainless steel welded pipes will lead to stress concentration, reduce bearing capacity, shorten service life and even cause brittle fracture. General technical regulations stipulate that cracks, incomplete penetration, unfused and surface slag are not allowed; defects such as undercut, internal slag and pores cannot exceed certain allowable values, and must be thoroughly removed and welded for excessive defects. Make up. The causes, hazards and preventive measures of welding defects of common stainless steel welded pipes are briefly described below.

-

Stainless steel welded pipe is characterized by high temperature resistance and corrosion resistance. What is the reason for the high temperature resistance of stainless steel welded pipe ?

-

With the popularization of stainless steel welded pipe applications, the performance of stainless steel welded pipes has attracted more and more attention. Corrosion occurs when stainless steel welded pipes are used for a long time. What causes corrosion of stainless steel welded pipes?

-

Compared with carbon steel, high temperature stainless steel welded pipe has a slightly higher density than ferrite and martensitic stainless steel, and slightly lower than high temperature resistant stainless steel; resistivity is carbon steel, ferrite type, martensite type and austenitic The order of the stainless steel is increasing; the order of the coefficient of linear expansion is similar, the austenitic stainless steel is the highest and the carbon steel is the smallest; the carbon steel, ferritic and martensitic stainless steel are magnetic, and the austenitic stainless steel is non-magnetic, but its When cold work hardening forms a phase transformation, it will generate magnetism, and the martensite structure can be removed by heat treatment to restore its non-magnetic properties.

-

Stainless steel decorative pipe elbows often have problems in the processing process. If you are not paying attention, the angle may be too large or broken. For this, Wuxi Silver Coral Stainless Steel Co., Ltd. summarizes some of the stainless steel decorative pipe elbows. Note, for your reference only:

-

Many people don't understand the difference between stainless steel decorative tubes and product tubes. Why is the same specification, the price is so different? Now Rongxingyuan Xiaobian will let you know the difference between decorative tubes and product tubes.

-

The stainless steel decorative pipe is a stainless steel pipe made by welding a steel plate or a steel belt through a unit and a die. Let's take a look at the process flow of the stainless steel decorative tube with the small series.

-

Commonly used stainless steel decorative tubes on the market are polished tubes with a surface that is bright. So what factors affect the polishing of the stainless steel decorative tube surface?

-

Stainless steel decorative tubes , in general terms, are steel that is not easily rusted. The stainless steel tube has both rust and corrosion resistance due to the formation of a chromium-rich oxide film (passivation film) on its surface. This rust and corrosion resistance are relative. The test shows that the corrosion resistance of steel in the weak medium such as atmosphere and water and oxidizing medium such as nitric acid increases with the increase of chromium content in steel. When the chromium content reaches a certain percentage, the corrosion resistance of steel is abrupt. From rust to rust, from corrosion resistance to corrosion resistance.

-

Features of cold drawn precision steel pipe

-

The current cost of capital is down. Compared with the cost of capital that was priced at 1-2 a month last year, the borrowing costs of traders have now declined. Although the financial pressure has improved, the current economic outlook is not optimistic, and the seamless pipe in East China ,Small-diameter seamless steel pipes and seamless steel pipes are at a low level.

-

Stainless steel seamless pipe product features:

-

20# cold drawn seamless pipe spot resource specifications :

194*20

325*14