-

What is LSAW pipe means

LSAW (Longitudinal double submerge arc welding) carbon steel pipe is a type of SAW pipe made of steel plates that were hot rolled by JCOE or UOE forming technology. JCOE technology represents the shaping and forming processes involved during manufacturing as well as the inner and outer welding and cold expansion carried out after welding.

-

Sour services steel pipe is applied for pipelines in the corrosive environment.

As we know, line pipe corrosion is an important factor affecting its safety service and service life. It will cause the leakage of oil and gas pipeline, some cases even explosion.

Pipe corrosion has a big threaten to personal safety and environment pollution, so the production of sour service pipe is important. At present, the manufacture inspection standard for acid pipe mainly according to API Spec 5L.

-

Always in pipeline systems we met the material with NACE MR0175/ISO 15156 pipe or fittings, so do you really know what is the major differences between NACE carbon pipe and normal carbon steel pipe? And how is the cost for nace material?

-

Steel pipe pile is a type of steel piling material. It is usually referred to the carbon steel pipe manufactured in seamless or welded (SSAW or LSAW), used for supporting and stabilizing the foundation of a building. So a pipe pile is a structural construction material.

-

Fire sprinkler pipe and related fittings are generally made of carbon steel or ductile iron material and used to carry water or other liquid to connect firefighting equipment. It is also called fire protection pipe and fittings. According to the corresponding rules and standards, the fire pipeline need to be red painted, (or with red anti corrosion epoxy coating), the point is to separately with other pipeline system. Since the fire sprinkler pipe usually installed in a static position, it requires a high level and restrict quality control.

-

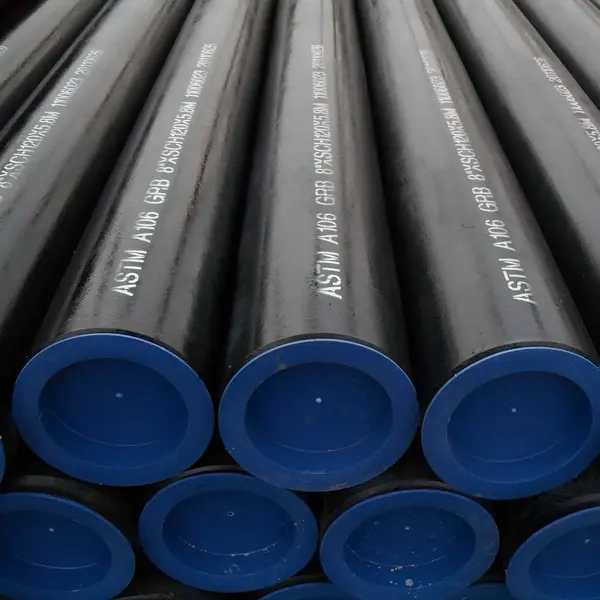

As we know ASTM A106 Grade B pipe is one of the most popular seamless steel pipes applied in different industries. Not only in pipeline systems like oil and gas, water, mineral slurry transmission, but also for boiler, construction, structural purposes.

-

First identified in the 1700s, nickel was first known as ‘kupfernickel‘ because it was found in a rock that looked like copper ore. Miners once thought that nothing of nickel, thinking that this element makes it difficult for them to extract copper from rocks. Little did they know that nickel would soon become one of the most essential industrial metals in the world.

-

Steel is one of the most common materials in the world, representing an industry that produces 1.3 billion tons a year, and it is a material used throughout the construction of many architectural fabrications.

-

As industrial applications have evolved and grown more complex, the piping products and systems that serve them have had to keep pace.

-

Straight pipe joints Basics pressure pipe

straight seam steel pressure conduit basic concept

-

Straight seam steel pipes in industrial production often have two options, one is the use of ordinary straight seam steel pipe, and the other is a straight seam steel pipe with more and better performance. In the process of long-term production practice, companies have generally formed a consensus that this straight seam steel pipe with more good characteristics is superior to ordinary straight seam steel pipe in many aspects. This straight seam steel pipe is slightly better than the ordinary straight seam steel pipe, mainly because the straight seam steel pipe has several characteristics that ordinary straight seam steel pipe does not have.

-

Straight seam steel pipe production process. According to the production process, straight seam steel pipes can be divided into high-frequency straight seam steel pipes and submerged arc welded straight seam steel pipes. Submerged arc welded straight seam steel pipes are further divided into UOE, RBE, JCOE steel pipes according to their different molding methods. The following describes the most common molding processes for high-frequency straight seam steel tubes and submerged arc welded straight seam steel tubes.

-

Straight seam steel pipe is fully analyzed. The application of submerged arc welded straight seam steel pipe in the industry is obvious to all. Its wide application must be due to its unique advantages. However, as a successful business, we should fully understand this product, and analyze the advantages and disadvantages of hot-rolled steel pipe.

-

Straight seam steel pipe standard: (GB/T3091-2008) This standard includes straight seam steel pipe high frequency resistance welding (ERW straight seam steel pipe),

-

First clean the oil, paint, water, rust, etc. of the weld, and then open the groove according to the wall thickness, the thicker will open larger, the thin will open smaller (angle grinder) Then there is the gap of the product, usually 1-1.5 times the diameter of the electrode or wire. If you accidentally open the groove, you can leave it smaller. Point welding is at least three points, generally four points are better. When welding, it should be welded in half and half, and the starting point should be better than about one centimeter of the bottom point, so that the joint is good from the opposite side. If the wall thickness is thick, it should be layered, at least two layers, and the second layer can be welded after the first layer is completely welded.

-

When the pipeline is initially laid, people may consider the terrain, or the direction of the pipeline. But again, in the process of using the pipeline, one of the most worrying things for people today is the leak. If there is a leak, it will bring a lot of problems. In order to solve this problem well, there is now a seamless steel pipe that allows people to worry about it anymore.

-

This week, the national galvanized pipe market is weakly consolidated, ranging from RMB 20-120/ton.

-

What are the main uses and advantages of hot-dip galvanized pipe? In order to improve the corrosion resistance of steel pipes, general steel pipes are galvanized. Most of the old houses use hot-dip galvanized pipes. Now the iron pipes for gas and heating are also hot-dip galvanized pipes, and hot-dip galvanized pipes are used as water pipes.

-

After using galvanized steel pipe, the life and use of the product can be guaranteed. One of the main things that is talked about today is to explain the storage method of galvanized steel pipe, and know that these storage methods will not cause any problems when they are used.

-

The carbon steel pipe is made of a steel ingot or a solid round steel through a perforation, and then is formed by hot rolling, cold rolling or cold drawing. Carbon steel pipe plays an important role in China's steel pipe industry.

-

The continuous casting process includes horizontal continuous casting and curved continuous casting, solid continuous casting and hollow continuous casting. The application of the continuous casting blank simplifies the feeding condition of the extrusion, reduces the processing cost of the extruded bad material, and realizes the "short process" of the extrusion process .