-

The seamless high temperature service pipe used for high temperature and high pressure service is usually considered as a heat exchange tube running at 400 degrees Celsius to 1100 degrees Celsius.

High temperature service alloy steel tubes are called chromium molybdenum tubes. There are basically two types of high temperature steel pipes: 1. high temperature carbon steel tubes and 2. superalloy tubes.

-

DMH United Steel offers an extensive range of seamless steel pipes for low and medium pressure service. Applications for heat exchange tubes, streaming tubes, low and medium pressure boiler water wall, economizer, reheater, superheater and steam pipeline.

In the main steel grade as ASTM A179, ASTM A192, GB3087-2008.

-

EN 10216 Part 1: non-alloy pipes with specified properties at room temperature

EN 10216 Part 2: non-alloy pipes with specified properties at higher temperatures

EN 10216 Part 3: alloy pipes made from fine-grained steel for any temperature

-

DMH UNITED STEEL INDUSTRY offer an extensive range of Line pipes used in sour service environment.

The line pipes can be used for a wide range of petrol and gas transportation under sour service environment. Sour service line pipes are produced accord to GB/T9711.3 and API 5L/ISO31813-2007.

-

Seamless service for cryogenic service is applicable to 16MnDG, 10MnDG, A333 Gr.1, Gr.3, Gr.1 of main standard GB / T18984-2003, ASTM / ASME A / SA333.

Sunny Steel provides a wide range of seamless steel tubes for cryogenic services.

The GB / T18984-2003 standard is applicable to low temperature pressure vessel pipes from -49 to -148 degrees F and seamless steel tubes with low temperature heat exchange tubes.

The ASTM / ASME A / SA-333 level allows cryogenic service to be below 150 degrees Fahrenheit. Materials are always provided under standardized conditions and the Charpy impact is tested to a specific temperature range to ensure that the required service temperature is met.

-

Our fluid seamless steel tubes are widely used for fluid transportation, water conveyance (sewage discharge, diversion works), long distance transportation of oil and natural gas and fluids.

-

Seamless Steel Tubes for Mechanical and Automobile usage for Backbone of Automobile and rear axle tube, manufacturing and processing of precision equipments, instruments and apparatus.

Your tubular products representative will be happy to work with you to develop the information that is required. Sunny Steel supply a 1/2 million foot inventory of carbon steel pressure tubing including boiler tubes, condenser tubes and heat exchanger tubes all made in the China.

Our carbon steel pressure tubing inventory is manufactured in accordance with ASME SA-178 A and/or ASME SA-214 in diameters of 3/4″ through 4”.

-

Seamless steel pipe for shipbuilding is mainly used for piping system, 1 grade and 2 stage pressure piping for boiler and super heating unit.

Seamless steel pipe for shipbuilding is shipbuilding steel pipe designed for ship boiler, super heater and pressure system. Marine steel pipe can be widely used in CCS, DNV, LR, GL, ABS, BV, RINA, NK and other ships and Chinese national standards.

-

The main test terms are based on ASTM A213-09 and ASTM A1016

1. high pressure hydraulic test: at least 10 diagrams.

2. eddy current test, ultrasonic test

3. mechanical test

4. OD and WT tolerability tests.

-

London, June 25. According to data released by the World Steel Association on Monday, global crude steel production in May increased by 6.6% year-on-year to 155 million tons.

In the world's largest steel producer and consumer country, China, crude steel production increased to 81.1 million tons, an increase of 8.9% from May 2017

-

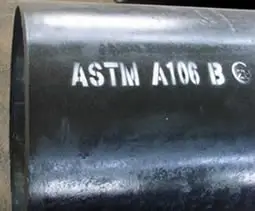

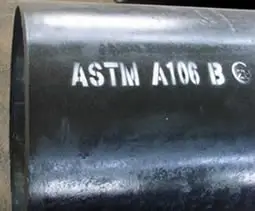

The ASTM standard helps to classify, evaluate and specify the material, chemical, mechanical and metallurgical properties of different types of steel, which are mainly used for the production of mechanical components, industrial components and building components, and other accessories related to them.

Steel can be carbon, structure, stainless steel, ferrite, austenite and alloy type

-

Static water pressure or nondestructive power test

Heat treatment: the minimum temperature is 650.

Surface condition: no fouling. Slight oxidation will not be regarded as scaling.

The flattening test, the combustion test. Flanges test, hardness test, hydrostatic pressure test

-

GB 5310- 2008 standard is applicable to seamless tubes for making steam boiler whose pressure is high or higher and seamless tubes used as pipelines.

-

We supply all types of boiler tubes and pipes including seamless, heat-resistant steel pipes in accordance with DIN / EN and ASTM A / ASME SA.

Boiler tubes

-

ASTM A500 tube is a standard specification for cold-formed welded and seamless carbon steel structural tubing in round, square and rectangular shapes. ASTM A500 is the most common specification in North America for Hollow Structural Sections (HSS).

APPLICATIONS

ASTM A500 applications include structural supports, building columns, highway signs, oil field services and communication towers.

-

CHARACTERISTICS

A500 steel pipe can be subjected to most of the usual fabricating operations. Ductility is good. It bends well, flattens, cuts, punches, flares and flanges easily, and can be welded by the commonly-used techniques and practices.

APPLICATIONS

Common uses for ASTM A500 pipe include hand rails, posts, storage racks, displays, furniture, etc.

-

When steel pipe is completed and operational, it is the result of cooperation between a number of parties in the supply chain. These parties perform steps which are sequential and overlapping involved in the design, manufacturing, blasting, coating, handling, storage, transport and construction of steel pipe.

-

150# Plate Steel Slip-On Flange

Sizes ranging from 1-inch to 18-inch

304 Stainless Steel Plate Slip-On Flange, 150# Drilling

Sizes ranging from 1-inch to 12-inches

316 Stainless Steel Plate Slip-On Flange, 150# Drilling

Sizes ranging from 1-inch to 12-inche

-

As the name suggests, seamless pipes are pipes without joints or welded joints, rather than welds or welded pipes. In joints or welded pipes, joints or welded joints are the weaker parts of pipelines, which limit the strength of pipes to achieve the strength of welded joints. Seamless pipe has no such joint, so it has uniform structure and strength on the whole pipe. Therefore, seamless tube can withstand higher pressure, higher temperature, higher mechanical stress and corrosive atmosphere, and is widely used in oil and natural gas, oil refinery, petrochemical, chemical, chemical fertilizer, electric power, automobile, bearing, mechanical and structural applications.

-

Hot-rolled seamless steel pipe production base deformation process can be summarized as three stages: perforation, extension and finishing.

-

There are cracks in the welding process or design of the stainless steel pipe joint at the other joint. In effective corrosion sites, the crack must be wide enough to allow corrosive electrolyte to enter the stagnant zone. The width of the corrosion crack is several meters wide, but it is not absolute. The critical crack size leads to corrosion.