-

Differences in manufacturing process:

Galvanized steel pipe and seamless steel pipe are two kinds of steel tubes. The surface of galvanized steel tube is galvanized. It may be welded pipe, it may also be seamless tube. Seamless steel pipe is the corrosion resistance of seamless galvanized pipe in the manufacturing process, and seamless steel pipe can bear high pressure. Galvanized steel pipe is not easy to rust, galvanized steel pipe is not easy to rust, galvanized steel pipe is more than seamless steel pipe. If it is used for balcony, it is best to use galvanized light tube, not suitable for using seamless steel tube balcony, because the wall thickness of seamless steel pipe is heavy, and the cost of seamless steel pipe is higher than that of galvanized steel pipe, and the galvanized steel pipe is very durable. Longer life than seamless steel pipe. If the quality is good, the use of more than 20 years should not be a problem, of course, welding and painting should be done, and will not affect the service life of galvanized steel tube.

-

Quenching and tempering: quenching after high temperature tempering is called quench hardening. High temperature tempering refers to the tempering between 500-650 degrees C. Quenching and tempering can make the performance and material of the casing to be adjusted to a large extent. Its strength, plasticity and toughness are better and its comprehensive mechanical properties are better. The tempered Soxhlet body was obtained by tempering. Tempered Soxhlet is formed by tempering martensite and magnified over 500 to 600 times under an optical microscope. It is characterized by the distribution of carbides in ferrite matrix carbon in composite structure. It is also a tempering structure of martensite, a mixture of ferrite and granular carbide. At this point, the performance of ERW bushing in ferrite is basically no carbon supersaturation, and carbide is also a stable carbides. It is a balanced tissue at room temperature.

-

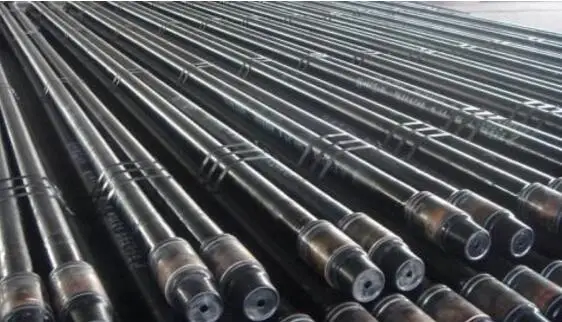

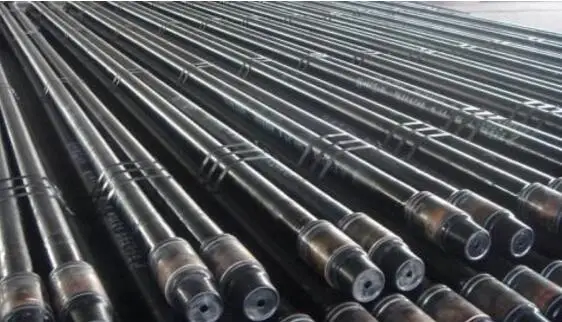

The ERW bushing is a large diameter pipeline that acts as a fixed oil well and natural gas well or well. The casing is inserted into the borehole and fixed with cement to prevent the borehole from separating the formation from the borehole and ensure drilling mud circulation for drilling.

-

steel pipe material

-

steel pipe grade

-

Pipe Standard

-

Name: ASTM A519 Seamless Carbon and Alloy Steel Mechanical Tubing

Application:For mechanical and high-pressure settings, as well as for transporting steam, water and gas.

Size (mm): O.D.: 20∼180; W.T.: 2-30; L: max 12000

-

ASTM A179 cold drawn seamless steel pipe is mainly used in the metal structure equipment of various industries. It is mainly to soak the rust of steel parts into the molten zinc solution of 440 to 460 degrees C, so that the zinc coating on the surface of the steel plate is attached to the surface of the steel, thus the purpose of anticorrosion is to be played. This is an effective way of metal corrosion. The main features are as follows:

(1) the ASTM A179 cold drawn seamless steel tube manufacturer covers the compact and compact zinc layer on the surface of the cold drawn seamless steel tube. It can avoid the cold drawn seamless steel tube matrix and any contact with the corrosion solution to protect the steel matrix from corrosion. In the general atmosphere, the surface of the zinc layer forms a thin and dense Zinc Oxide surface, which is hard to dissolve in water, so the steel matrix plays a protective role. If Zinc Oxide and other components in the atmosphere produce insoluble zinc, the antiseptic effect will be better.

(2) iron zinc alloy layer, combined with dense and unique corrosion resistance, in marine atmosphere and atmospheric environment.

(3) ASTM A179 cold drawn seamless steel tube has strong wear resistance due to the combination of strong zinc and iron mixture.

(4) due to the good ductility of zinc, the alloy layer and the steel base are attached to a solid, so the hot rolled parts can be formed by cold, rolling, pulling, bending, etc. without damage to the coating.

(5) the hot dip galvanized steel structure, equivalent to one annealing treatment, can effectively improve the mechanical properties of the steel matrix, eliminate the stress of the steel forming and welding, and be beneficial to the turning of the steel structure.

(6) the surface of cold drawn seamless pipe after hot-dip galvanization is bright and beautiful.

(7) the pure zinc layer is the hot-dip galvanizing layer of zinc coating. Its properties are basically close to pure zinc and has ductility, so it has great flexibility.

-

1. ASTM A53 thick-walled seamless steel pipe hot rolling position were from the steel head 38,118m, mainly in the middle of the strip.

2. It is speculated that the gap starts at the middle of the width of the strip, because the rolling force and shear force in the rolling process cause the gap to be stretched to form a macroscopic macropore.

3. Seamless steel pipe in the cold rolling production process interrupted with the fracture surface smooth, no obvious before and after fracture surface defects.

The microstructure of the fracture was observed, and the typical ductile ductile fracture morphology was observed. At the same time, the fracture was layered, the central dimple was larger, the dimple was narrowed near the surface, and the crack appeared the center fracture And the depth of fracture at the center is deep, and it is presumed that the stratified topography is closely related to the central segregation.

-

How to prevent the J55 ERW casing from clasping and attaching, the hollow section of the API ERW sleeve, a large number of pipes used for conveying fluid, such as oil, natural gas, gas, water transportation, etc. The use of steel pipe manufacturing ring can improve the utilization of materials, simplify the manufacturing process, save material and processing time, such as rolling bearing rings, Jack suites, and so on, has been widely used in the manufacture of steel.

-

Speaking of steel pipe materials, the professional manufacturers of steel pipe manufacturers are constantly improving their product quality requirements, but some necessary wear and tear is indispensable. Oxidation corrosion is sometimes present. What is the reason?

-

The three processes of electrochemical corrosion of ASTM A179 cold drawn seamless pipe are as follows:

First of all, for urban gas system, because of the dense underground pipe network, the external power supply cathodic protection will interfere with other cold drawn steel tubes, which will cause their own interests and affect their family status. However, the use of the sacrificial anode protection method for the use of the cold drawn steel pipe than the negative metal and the cold drawn steel pipe does not appear. Therefore, the urban gas pipeline should adopt the antirust coating and the sacrificial anode combination.

-

1. ASTM A53 thick wall seamless steel tube hot rolling position away from the steel head 38118m, mainly located in the middle of the steel strip.

2. it is speculated that the gap formed by the rolling force and shear force during the rolling process is macroscopically large, so the gap begins in the middle of the strip width.

3. seamless steel pipe is smooth in the cold rolling process, and there is no obvious defect on the surface before and after fracture.

The microstructure of fracture surface was observed and typical ductile ductile fracture morphology was observed. At the same time, the faults are distributed in layers, the central pits are larger, the pits are narrowed near the surface, the cracks appear in the center and the depth of the central fracture is deep, and the stratified topography is closely related to the central isolation.

-

There are more standards for steel products in the United States, mainly in the following categories:

ANSI - the national standard of the United States

AISI - American Steel Standards Association

-

Other countries and ISO stainless steel standards are provided to hot rolled (forged) steel, in addition to heating pressure processing steel, general heat treatment delivery (heat treatment requirements need to be stipulated in the contract). After heat treatment, surface treatment or surface treatment such as pickling, shot peening or turning and peeling is required. For cold or cold drawn or cold drawn steel or cold working conditions, or after heat treatment of pickling or shot peening or cold processing after heat treatment, after forming, grinding, polishing or further to varying degrees of hardening treatment and other state delivery.

-

The ASTM material standard is formulated by the American Institute of materials and testing. ASTM material standards can include chemical, mechanical, physical and electrical properties of materials. These standards include the description of test methods for building materials, and the size and shape of these materials. Local laws require that concrete and other building materials meet the ASTM standard before construction. It is widely used in ASTM A53 and ASTM A106.

-

The German n-TV news website reported that Eurofer severely criticized the United States for imposing punitive tariff measures, claiming that Trump’s move was “harmful” and could result in the loss of tens of thousands of jobs in Europe. A Eurofer spokesman said that European steelmakers will suffer heavy losses in their most important export markets and demand that the EU immediately issue protection measures for the steel industry. The U.S. tariff policy will result in a significant shift of the other involved steel companies to the European market. If the import of steel is significantly increased and the development of European companies is jeopardized, the introduction of protective measures is in principle in conformity with the WTO rules. Eurofer officials said that the European Commission has announced that it will take immediate action. This is a good thing. When the United States damages the international trading system, the EU cannot stand idly by.

-

On the 12th, local time, the US Department of Commerce decided in the final judgment of the annual anti-dumping tariffs for oil-specific pipes to impose a 75.81% anti-dumping tariff on South Korean steel company Nexteel and 6.75% anti-dumping tariffs on companies such as Worldsteel.

-

Spiral steel pipe should be tested before the factory mechanical properties and flattening test and flaring test, and meet the requirements of the standard requirements.

-

1. repair the mouth

In order to ensure the welding quality, the welding is carried out before the complete inspection and correction, so that the pipe end, the oblique angle, the blunt edge and the roundness are in accordance with the interface size. When the individual steel pipe needs to be processed in the field, the gas welding is used and the slag is removed and the grinding wheel is reused with the grinding wheel.

The operation procedure of the counter is to check the size of the interface connector, to clean the cavity, to determine and adjust the longitudinal joint of the staggered position of the steel tube, to the first pipe straight, to adjust the size of the gap between the counterpart, to the leveling mouth, to straight to straight, to the light point welding.

-

Why does oil drilling choose thick-walled seamless steel tubes?