-

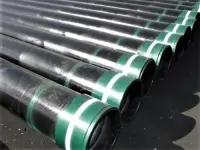

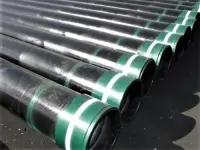

ISO 11960:2020(E) – Petroleum and natural gas industries — Steel pipes for use as casing or tubing for wells. This article will briefly introduce ISO 11960 casing and tubing for wells.

-

Mild steel pipe (MS pipe) is a type of carbon steel pipe made from low-carbon steel. It typically contains a small percentage of carbon (below 0.25%) along with elements such as silicon, manganese, phosphorus, and sulfur.

-

The weight of a drill pipe is primarily determined by its size, material (steel grade), and length. Typically made from high-strength steel, drill pipes are engineered to endure the extreme pressure and torque encountered in drilling operations. The following overview outlines the general weight ranges and the main factors influencing them.

-

Constructing a water well involves many important decisions, and one of the most critical is selecting the right well casing pipe. The casing pipe not only supports the well structure but also protects the wellhead and ensures water quality. Common materials include carbon steel, stainless steel, PVC, and fiberglass (FRP).When choosing the best option, consider several factors—such as pipe specifications, well depth, geological conditions, water quality, budget, and service life.

-

Steel plays an irreplaceable role in modern construction, manufacturing, and infrastructure. Among the many steel products available today, the DN808 steel pipe stands out for its exceptional strength, durability, and versatility. Let’s explore the key characteristics, main applications, and future development trends of this remarkable material.

-

As the name suggests, mild steel casing pipe is made from low-carbon steel—one of the most versatile and widely used materials in the steel industry. Thanks to its low carbon content, mild steel combines strength with excellent formability and weldability. Through specialized manufacturing processes, mild steel casing pipes inherit these core qualities and gain enhanced performance characteristics, making them a quiet yet essential player in countless industrial and construction applications.

-

Casing joint strength refers to the ability of a threaded connection to withstand various mechanical loads. It is not a single metric, but rather a reflection of comprehensive performance under real downhole conditions — including tension, compression, bending, and internal/external pressure.

-

Drill pipe is a critical component in oil and gas drilling as well as geological exploration, mainly made from seamless steel pipes. Here's an overview of drill pipe price and cost.

-

In pipeline engineering, pup joints and pipe reducers are two essential types of pipe fittings. While both serve as connectors, they differ significantly in structure, function, manufacturing, and installation methods. Understanding these differences is crucial for ensuring pipeline safety, efficiency, and reliability.

-

OCTG drill pipe, often called the “lifeline” of oil and gas drilling. Nondestructive testing (NDT) is a key quality assurance measure for OCTG drill pipe, applied from manufacturing to decommissioning, and must comply with industry standards such as API 5DP.

-

Angle steel is one of the most widely used steel structures.The connection process of angle steel is the “bond” that links structural members together. Connection quality directly affects structural stability and safety. Poorly executed connections may lead to equipment failure or even building collapse. Therefore, mastering scientific and reliable connection techniques is essential for the efficient application of angle steel.

-

As a core material in oil and gas exploration, OCTG pipes are engineered to withstand complex downhole conditions. With adaptability, reliability, and full-process coverage, they have become indispensable in ensuring safe and efficient oil and gas production. Their advantages can be highlighted in the following aspects.

-

Although OCTG Pipe and Line Pipe are both essential steel pipes in the energy industry, they serve very different purposes. Their distinctions lie in definition, performance requirements, structural design, and applicable standards. The comparison can be made across five core dimensions.

-

The drill pipe is a vital component in the drilling process, primarily responsible for transmitting torque and transporting drilling fluid. By gradually adding drill pipe sections, the wellbore is extended to the desired depth. Selecting the appropriate drill pipe size and length is crucial, as it directly affects drilling efficiency, operational costs, and safety.

-

The service life of oil casing and tubing is closely tied to the entire life cycle of an oil well, often determining how long the well can operate safely and efficiently. In oil and gas production, casing pipes are typically used once, cemented in place, and permanently left underground. Their longevity depends on multiple factors, including material quality, threaded connections, geological conditions, construction practices, and ongoing maintenance. In most cases, casing service life ranges between 15 and 30 years, though actual performance may vary significantly.

-

Galvanized steel pipe is widely used in plumbing, construction, and outdoor projects because of its excellent corrosion resistance. However, welding galvanized pipe requires extra care compared with standard steel pipe. The zinc coating that protects the pipe can release hazardous fumes when heated, and improper welding may compromise both the weld quality and the protective layer. This guide explains how to weld galvanized steel pipe safely and effectively.

-

In oil, gas, and geological exploration drilling, the drill string assembly plays a decisive role in ensuring drilling efficiency and wellbore quality. Two essential components within this system are the Heavy Weight Drill Pipe (HWDP) and the Drill Collar. While they may look somewhat similar, their structure, functions, and applications differ significantly. Understanding these differences helps engineers and drilling teams choose the right tool for the right job.

-

Pipe bending is a critical process in many industries, from construction and shipbuilding to oil & gas and manufacturing. One of the most important parameters to understand during this process is the bend radius. The bend radius directly affects pipe integrity, flow efficiency, and installation requirements.

-

ERW (Electric Resistance Welded) pipe is one of the most widely used steel pipes in modern industries. It is manufactured by rolling steel sheets or strips and welding them longitudinally using electric resistance. The result is a strong, cost-effective pipe with a smooth finish and uniform wall thickness. But what exactly is ERW pipe used for?

-

Schedule 80 steel pipe refers to a wall thickness classification defined by the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME). The actual wall thickness of Schedule 80 pipe depends on its nominal pipe size (NPS) — the larger the diameter, the thicker the wall in absolute terms.

-

When it comes to steel pipes, corrosion resistance is always a key concern. One of the most commonly used methods to enhance durability is galvanization. Among the different galvanization techniques, pre-galvanized steel pipes stand out as a widely adopted solution in construction, infrastructure, and industrial projects.