-

As we know ASTM A106 Grade B pipe is one of the most popular seamless steel pipes applied in different industries. Not only in pipeline systems like oil and gas, water, mineral slurry transmission, but also for boiler, construction, structural purposes.

-

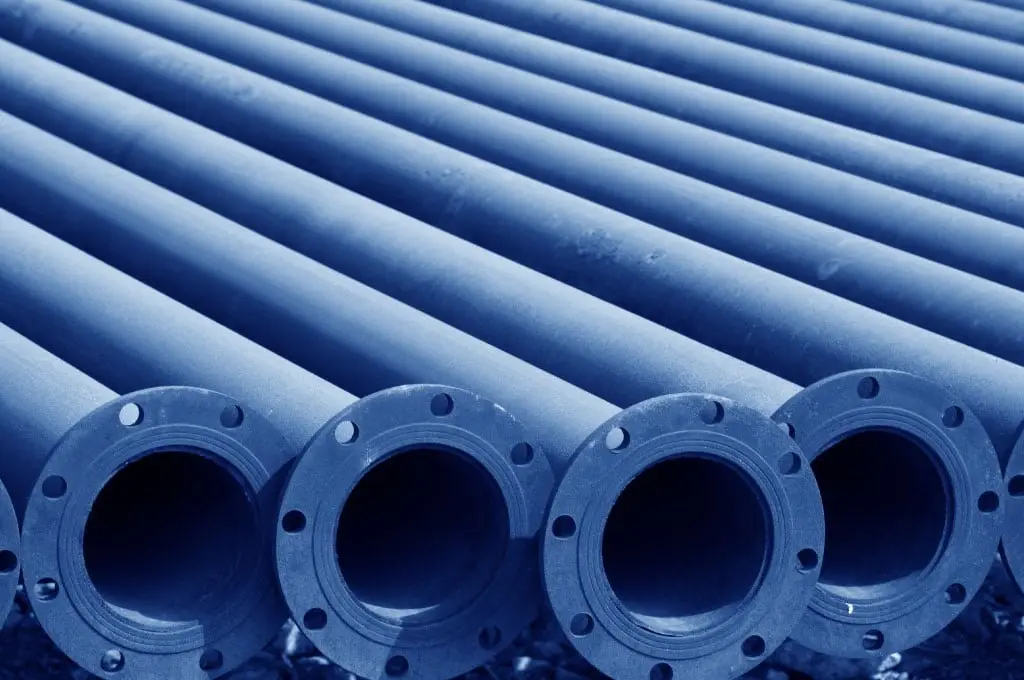

Polyurethane direct buried seamless insulation pipe has become a mature advanced technology in developed countries. China's heating engineering technicians have passed this research to promote this technology to promote the development of domestic pipe network technology to a higher level. Polyurethane direct-buried insulation tube is made of high-performance polyether polyol composition and multiple methyl polyphenyl polyisocyanate as raw materials, and then chemically foamed. It is widely used in indoor and outdoor pipelines and central heating. Pipe, chemical, pharmaceutical industry pipelines and other insulation, cold preservation projects. Polyurethane polyurethane direct buried seamless insulation pipeshould pay attention to the installation and explanation:

-

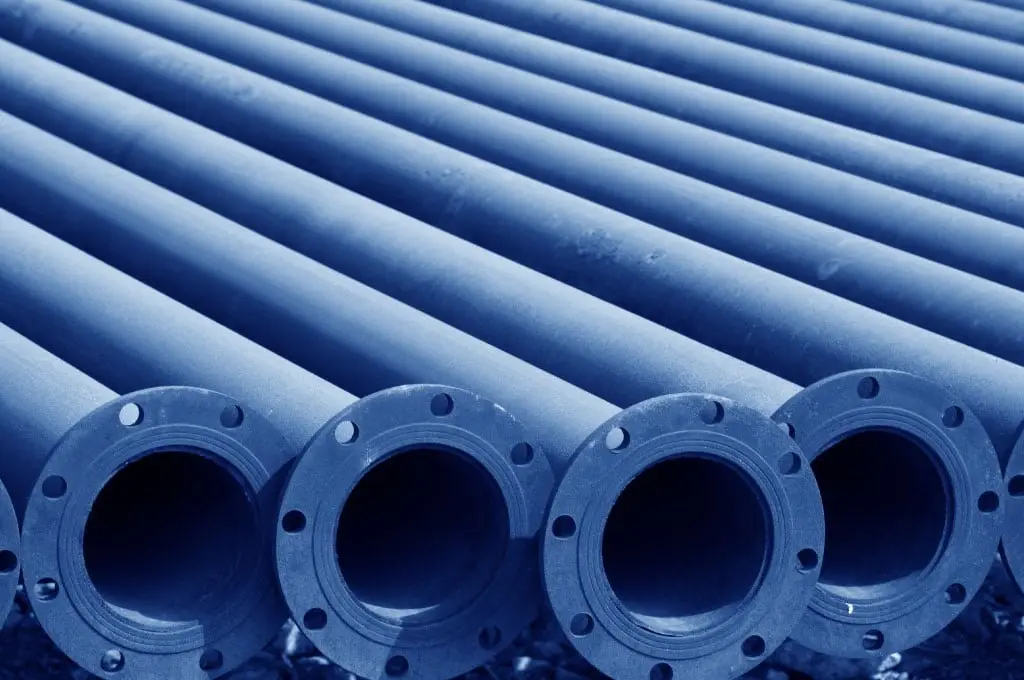

Insulation steel pipe high-density polyethylene polyurethane insulation pipe, polyurethane direct-buried insulation pipe is widely used in liquid and gas transportation pipe network, chemical pipeline insulation engineering petroleum, chemical, centralized heating and heating network, central air-conditioning ventilation pipe, municipal engineering. The high temperature prefabricated direct buried thermal insulation pipe is a direct buried prefabricated thermal insulation pipe with good thermal insulation performance, safe and reliable, and low engineering cost. It effectively solves the problem of insulation, sliding lubrication and waterproofing of exposed pipe ends of 13O °C-6OO °C high temperature heat transfer prefabricated direct buried insulation pipe in urban central heating.

-

The prefabricated polyurethane direct buried thermal insulation pipe not only has the advanced technology and practical performance which are difficult to compare with the traditional trench and overhead laying pipeline, but also has significant social and economic benefits, and is also a powerful measure for heating energy saving. The adoption of direct buried heating pipeline technology indicates that the development of China's heating pipeline technology has entered a new starting point. With the further improvement and development of this advanced technology, it is imperative to directly replace the trench and overhead of the heating pipeline.

-

On November 12, the European Commission made a preliminary ruling on anti-dumping investigations on seamless steel pipe products originating in China, and decided to implement a six-month temporary anti-dumping measure. The head of the Trade Relief and Investigation Bureau of the Ministry of Commerce made a statement on this.

-

The proper selection and use of the electrode directly affects the chemical composition and performance of the weld, which is an important part of the preparation of large-diameter seamless steel pipe welding. Choosing the right electrode requires a comprehensive consideration of various factors, and sometimes it needs to be tested and verified before it can be finalized. The aspects to be considered are as follows: the performance requirements of the weld metal , the shape of the electrode, the rigidity and the position of the weld, the crack resistance of the weld metal, the processability, equipment and construction conditions, and economic rationality.

-

The difference between the size of SC and DN of galvanized steel pipe:

1.SC generally refers to the welded steel pipe , the language STEEL CONDUIT, is a shorthand for the material.

-

Galvanized pipe, also known as galvanized steel pipe, is divided into hot-dip galvanizing and electro-galvanizing. The hot-dip galvanizing layer is thick, with uniform coating, strong adhesion and long service life. The cost of electroplating is low, the surface is not very smooth, and its corrosion resistance is much worse than that of hot-dip galvanized pipes.

-

The high-frequency welded pipes are divided into the following four types. The definitions, functions and standard codes are as follows:

-

Hot dip galvanized square tubes are steels used in hot dip galvanizing processes. This process is a maintenance of steel itself. The medium of steel is prone to oxidation problems, and the application of hot dip galvanizing technology can prevent oxidation of steel. A thick, dense layer of pure zinc masks the exterior of the steel, preventing contact with any solution and keeping the steel substrate from corrosion.

-

To talk about the centralized classification of galvanized square tubes, we first look at the production process, which can be divided into hot-dip galvanized square tubes and cold-galvanized square tubes. It is precisely because of the difference in the addition of these two galvanized square tubes that they have many different physical and chemical properties. In general they have many differences in strength, tolerance and mechanical function.

-

High-pressure boiler steel pipe: high-quality carbon structural steel, alloy structural steel and stainless heat-resistant steel seamless steel pipe used for steam boiler pipes mainly used for manufacturing high pressure and above. These boiler tubes work under high temperature and high pressure by the party.

-

It is a long strip of steel with a hollow section and no seams around it. Steel pipes have a hollow section and are used in large quantities as pipes for transporting fluids, such as pipes for transporting oil, natural gas, gas, water and certain solid materials. Compared with solid steel such as round steel, the steel pipe is lighter in weight when it has the same bending and torsional strength. It is an economical section steel and is widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipes, automobile transmission shafts, bicycles. Shelf and steel scaffolding used in construction. The use of steel pipes to manufacture ring-shaped parts can improve material utilization, simplify manufacturing processes, save materials and processing man-hours, such as rolling bearing rings, jack sleeves, etc., and have been widely used in steel pipes. Steel pipes are also indispensable materials for various conventional weapons, and barrels, barrels, etc. are all made of steel pipes. Steel pipes can be divided into round pipes and shaped pipes according to the shape of the cross-sectional area. Since the area of the circle is the largest under the condition of equal circumference, more fluid can be transported by the circular tube. In addition, the circular section is subjected to a relatively uniform force when subjected to internal or external radial pressure, and therefore, most of the steel pipes are round pipes.

-

-

With the continuous development of China's economy, the country vigorously develops the energy industry. Long-distance oil and gas pipelines are an important way of energy security. In the process of anti-corrosion construction of oil (gas) pipelines, the surface treatment of steel pipes is the key factor determining the service life of pipelines. First, it is the premise of whether the anti-corrosion layer and the steel pipe can be firmly combined. According to the research institute's verification, the life of the anti-corrosion layer depends on the coating type, coating quality and construction environment. The surface treatment of the steel pipe affects the life of the anti-corrosion layer by about 50%. Therefore, it should be strictly in accordance with the anti-corrosion layer specification. The requirements of the surface of the steel pipe are continuously explored and summarized, and the surface treatment method of the steel pipe is continuously improved.

-

Stainless steel pipes of United Steel Industry Co., Ltd. are divided into ordinary carbon steel pipes, high-quality carbon structural steel pipes, alloy structural pipes, alloy steel pipes, bearing steel pipes, stainless steel pipes, and bimetallic composite pipes for saving precious metals and meeting special requirements. Plating and coating tubes, etc. Stainless steel tubes are available in a wide variety of applications, with different technical requirements and different production methods. The outer diameter of the currently produced steel pipe ranges from 0.1 to 4500 mm and the wall thickness ranges from 0.01 to 250 mm. In order to distinguish the characteristics, the steel pipes are usually classified as follows.

-

The main cause of corrosion in large diameter welded pipes

-

High-precision steel pipes In the conventional quenching method, the cold wind speed is not as fast as oil cooling, and is also lower than the isothermal and graded quenching molten salt. Therefore, increasing the pressure in the refrigerating chamber, increasing the flow rate, and applying the molar mass ratio of nitrogen to argon gas and hydrogen are common developments in vacuum absorption technology today. The vacuum carbonization temperature is generally higher than that of conventional gas carbonization. Usually, the penetration and diffusion of 920~1040 °C can be shown in two stages. It can also be used for pulse ventilation, heat preservation and multi-phase dispersion dispersion. The effect is better due to high temperature, especially surface. The clean, active, and vacuum carbonized layer formation rate is faster than conventional gas, liquid, and rapid carbonization. This is a reinforcing material, especially the use of heat treatment to strengthen the material, which is a more important means. Second, the cold deformation enhancement contributes to the uniformity of the metal deformation, because the deformed portion of the precision steel tube is hardened, and the portion where the deformation or deformation is small continues to develop. Third, the cold deformation strength can improve the safety of the member during use, and when the member is overloaded, plastic deformation occurs, thereby preventing the member from suddenly breaking due to strength.

-

Always in pipeline systems we met the material with NACE MR0175/ISO 15156 pipe or fittings, so do you really know what is the major differences between NACE carbon pipe and normal carbon steel pipe? And how is the cost for nace material?