-

This article will briefly introduce perforated and slotted casing and tubing.

-

The API standard, short for the American Petroleum Institute, is one of the key production standards for oil pipeline steel pipes.Here's an overview of casing and tubing grading in API 5CT.

-

OCTG (Oil Country Tubular Goods) casing and tubing are widely used in the steel industry. However, these materials often face the issue of decarburization. To prevent decarburization in OCTG casing and tubing, two primary methods can be employed.

-

API oil casing is a steel pipe used to support the walls of oil and gas wells, ensuring the proper operation of the well during drilling and after completion. This article will briefly introduce APl oil casing hydrostatic pressure test.

-

This article will briefly introduce the detection methods for industrial oil casing.

-

Batch number and heat number are essential identifiers in seamless steel pipe production.This article will talk about difference between seamless steel pipe heat number and batch number.

-

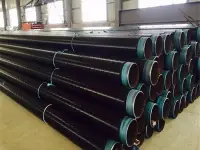

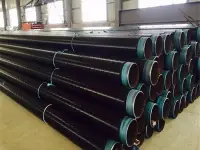

Large-diameter 3PE anti-corrosion steel pipes are renowned for their robust anti-corrosion properties and are extensively utilized in a variety of projects. This article delves into the details of large-diameter 3PE anti-corrosion steel pipes.

-

The classification of pipeline pressure levels refers to dividing the pipeline pressure levels into high pressure, medium pressure, low pressure and other levels according to the pressure that the pipeline must bear during work.

-

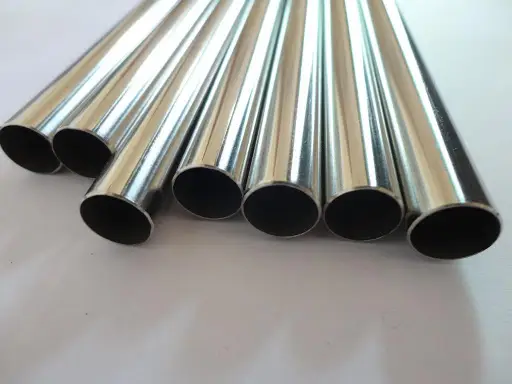

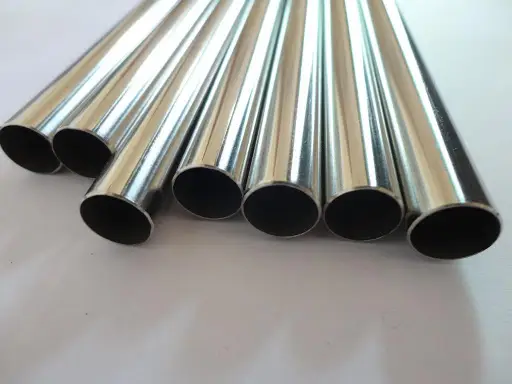

Galvanized steel pipe usually means that a layer of zinc is coated on the surface of the steel pipe to prevent it from rusting, thus improving its service life. So, does galvanized steel pipe have a shelf life?

-

The main reason why steel pipes need to be coated with anti-corrosion materials is to prevent corrosion and extend their service life. Corrosion refers to the erosion and damage of metal surfaces by oxygen, water, chemicals, electrochemical reactions and other factors. The following are the reasons why some steel pipes need to be coated with anti-corrosion materials.

-

Pipeline anti-corrosion encompasses measures aimed at retarding or preventing the degradation of pipelines caused by the chemical and electrochemical effects of internal and external media, or the metabolic activities of microorganisms. The primary purpose of pipeline anti-corrosion is to impede corrosion resulting from chemical or electrochemical reactions within pipelines.

Two predominant anti-corrosion methods are commonly employed for petroleum steel casing pipes: coating anti-corrosion and electrical protection.

-

Butt welding elbows are elbows that undergo a hot forming or forging process, and their primary method of connection is through direct butt welding to the pipe. These elbows are categorized based on their curvature radius, resulting in two main types: long radius butt welding elbows and short radius elbows. Additionally, they are classified according to pressure levels, aligning with approximately seventeen types that adhere to American pipe standards, with STD and XS being the most commonly utilized. Furthermore, based on the elbow angle, variations include 45-degree butt welding elbows, 90-degree butt welding elbows, 180-degree butt welding elbows, and elbows with other angles. In terms of material, butt welding elbows can be further divided into carbon steel elbows, alloy steel elbows, and stainless steel elbows.

-

Flanges play a crucial role in connecting pipes, valves, and other components in a piping system. The processing and connection of flanges involve specific steps and considerations to ensure a reliable and secure connection. Here is an overview of the flange processing and connection process:

-

Stainless steel pipe caps are end fittings or closures used to seal the ends of stainless steel pipes. Stainless steel pipe caps are typically designed to fit over the outside of the pipe's end and can be welded, threaded, or clamped in place, depending on the specific requirements of the application. They are available in various sizes, shapes, and materials, allowing them to be customized to suit the specific needs of different industries and projects. Read on to learn more about stainless steel pipe caps.

-

Guide to OCTG Tubing and Casing Couplings

-

Classification and implementation standards of steel pipes

-

Characteristics of steel pipes

-

steel pipe china

-

Application knowledge of aluminum alloy tube technology

-

Benefits of using thin-walled stainless steel pipe

-

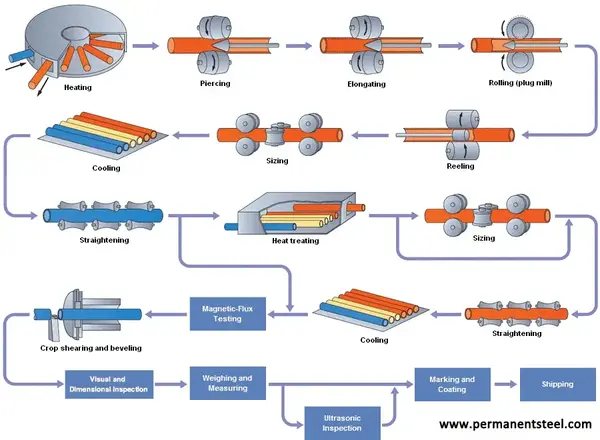

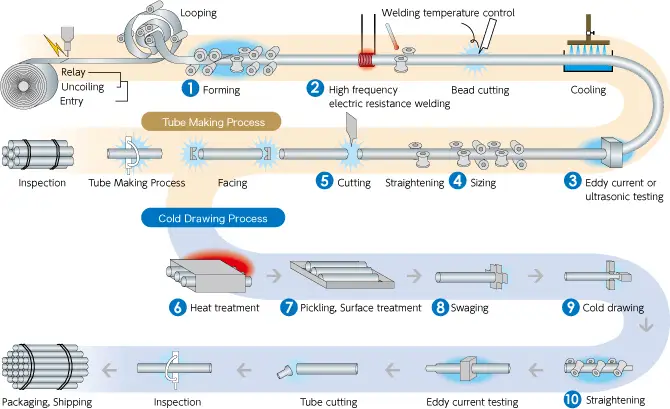

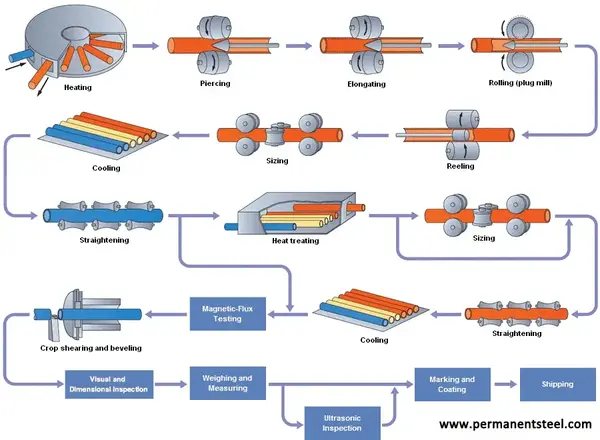

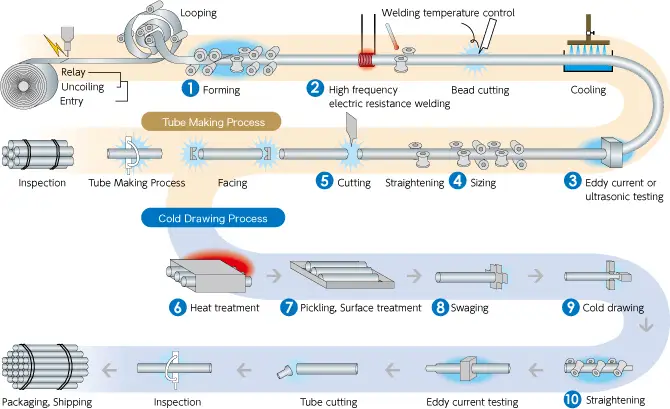

Steel pipe production process