-

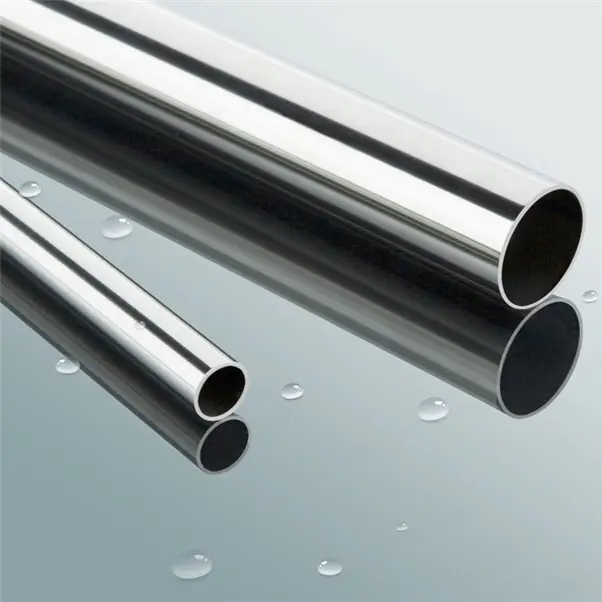

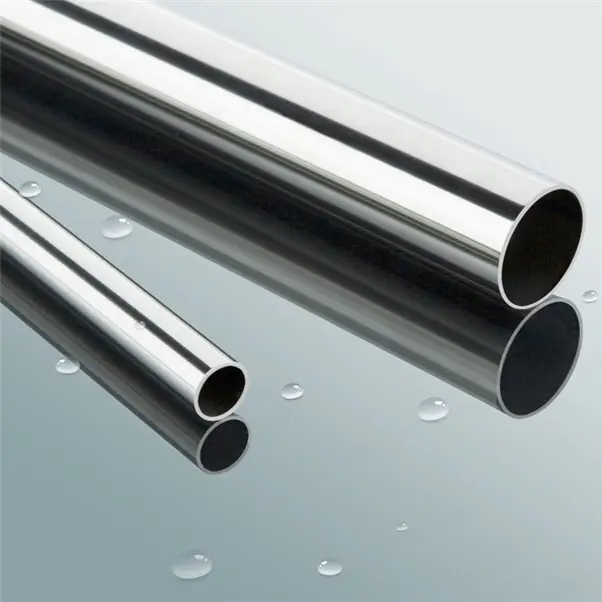

Stainless steel square tube is a kind of square tube material. In fact, it is a steel tube with the same length. The strip steel is processed and rolled. Usually, the strip is unpacked, flattened, crimped, welded to form a round tube, and then rolled into a square tube by a round tube and cut to a desired length. Stainless steel square tubes are mainly divided into two types: seamless and welded. The seamless square tube is formed by extruding a seamless tube. For those who want to buy stainless steel square tubes, it is necessary to know the specific price. So today, Xiaobian will tell you about the market price of 4*6 stainless steel square tube.

-

As a material with a wide range of applications, stainless steel has a very high market demand. So what is the current market for stainless steel? Next, Xiaobian will share with you the latest stainless steel price list, I hope you will like it.

-

The 316L is a model in stainless steel tubing and is currently very valuable in use and market demand. People who often pay attention to the price of stainless steel pipes will find that the price of stainless steel pipes fluctuates greatly, sometimes rising to exaggeration, and sometimes falling to the bottom. Only after we understand the factors affecting the price of stainless steel pipes can we be keenly aware of the fluctuations in the price of stainless steel pipes and respond well in advance. So what is the price of 316L steel pipe?

-

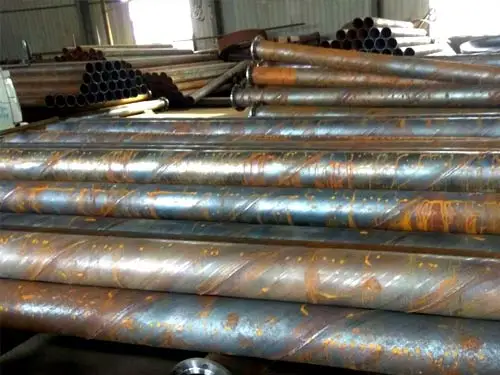

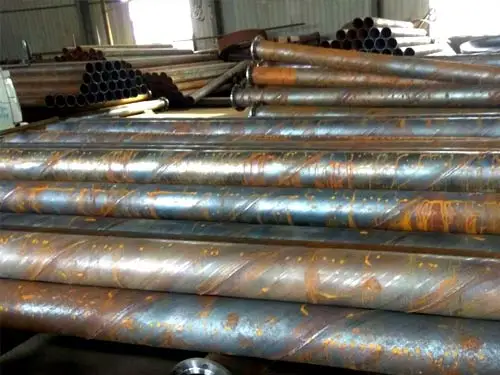

Precision spiral steel pipe is a kind of high-precision steel pipe after cold drawing or hot rolling. Because the inner and outer walls of precision spiral steel pipe have no oxide layer precision spiral steel pipe, high pressure and no leakage, high precision, high smoothness, no cold deformation, flaring, flattening without cracks, etc., it is mainly used to produce pneumatic or hydraulic components.

-

Burn-through and hydrogen-induced cracking in spiral steel pipe welding are hot topics at home and abroad. There are many influencing factors of these problems, including spiral steel pipe body, pre-weld treatment, welding process and post-weld treatment.

-

With the continuous development of China's economy, the country vigorously develops the energy industry. Pipeline long-distance oil and gas pipelines are an important way of energy security. In the anti-corrosion construction process of oil (gas) pipelines, the surface treatment of anti-corrosion spiral steel pipes determines the service life of pipelines. One of the key factors is the premise that the anti-corrosion layer and the steel pipe can be firmly combined. According to the research institute's verification, the life of the anti-corrosion layer depends on the coating type, coating quality and construction environment. The surface treatment of the anti-corrosion spiral steel pipe affects the life of the anti-corrosion layer by about 50%. Therefore, it should be strictly in accordance with the anti-corrosion layer. Standardize the requirements on the surface of steel pipes, continuously explore and summarize, and continuously improve the surface treatment methods of steel pipes.

-

There are many types of steel pipes and different uses, so their technical requirements are different and production methods are different.

-

The intermediate wave is formed at the side of the precision stainless steel strip and half of the center (1/4 inch from the side). The main reason is that the shape of the blank is not good and the intermediate roll shape curve is incorrect or the position is incorrect. The buck is a defect formed by the different English love in the thickness direction of the steel strip. The main reason is the result of the bending of the work rolls in the horizontal direction and the surface condition lubrication conditions of the upper and lower work rolls and the work mixed wear. Its manifestation is that it is rolled up laterally to form a "funnel shape".

-

Since the surface of the stainless steel tube will form a thin protective film, although the protective film is about 3×10-6 mm, it is very tough. Even if it is destroyed, as long as there is oxygen next to it, it can be regenerated immediately to prevent rust. As long as you know the characteristics of stainless steel and use it correctly.

-

The inner diameter of the stainless steel cylinder tube indicates the output force of the cylinder. The piston should slide smoothly in the cylinder, and the inner surface roughness of the cylinder should reach ra0.8um. The inner surface of the steel pipe column should be plated with hard chrome to reduce friction and wear and prevent corrosion. The cylinder material is made of high-strength aluminum alloy and brass, except for high-carbon steel pipes. This small cylinder is made of stainless steel. In corrosive environments, cylinders using magnetic switches or cylinders should be made of stainless steel, aluminum or brass.

-

What are the main factors affecting the service life of anti-corrosion insulation steel pipe ?

-

What should I pay attention to in the transportation of anti-corrosion insulation steel pipe ?

-

The products produced by our spiral steel pipe manufacturers often have waste products and finished products. We will not talk about these here. We directly enter the theme of today. We have made a technical update on the welding of the spiral steel pipe manufacturers. Too large directly causes a decrease in the proximity effect force, and also causes insufficient eddy current heat, and a bad crack is formed in the joint between the welds. This is a waste product.

-

The welding before the spiral steel pipe manufacturers basically used the welding rod to complete the welding, but following the development of our era, the electrode was gradually replaced by double-sided submerged arc welding. Why is Xiaobian saying this? In fact, our previous application of manual welding and double-sided submerged arc welding are protected by slag, but we have developed flux by hand-welded slag. Here we talk about the technology and rise of double-sided submerged arc welding.

-

Large diameter spiral tube production process

-

Spiral steel pipe is used for non-toxic 8710 anti-corrosion spiral steel pipe for drinking water , and is widely used in water quality pipeline.

-

The spiral tube is divided into three layers from the inside to the outside. The working steel pipe layer is generally made of seamless pipe ( gb8163-87 ) spiral welded pipe ( gb9711-88 ) according to the design and customer requirements. SY / t5038-92 ) and straight seam welded pipe ( gb3092-93 ). After the surface of the steel pipe is treated by advanced shot blasting, the corrosion grade of the steel pipe can reach the level of gb8923-1988 SA2 , and the surface roughness can reach the standard of gb6060.5-88 R = 12.5 microns.

-

The finished spiral steel pipe is discharged after water cooling, but after all, after high temperature heating, the temperature of the spiral steel pipe is still quite high after water cooling, so the following points should be noted after the spiral pipe is taken off the summer :

-

When stacking galvanized steel pipes, we must do a reasonable stacking and advanced first-hand

-

Difference between cold galvanizing and hot galvanizing

-

In recent years, many applications of hot rolled coils, especially thin gauge products, in the automotive industry, construction occupation, compressor occupation, etc.