-

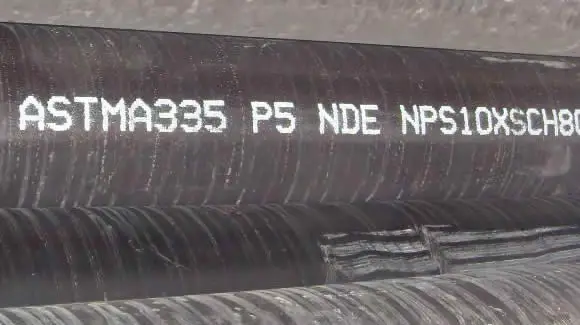

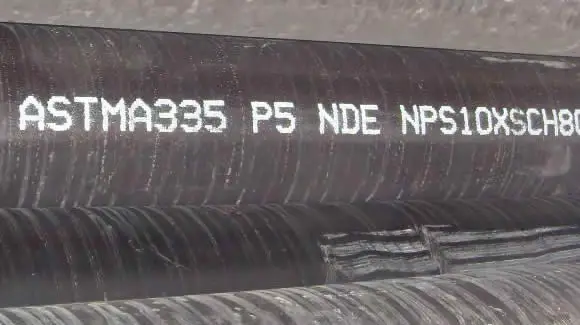

ASTM A335 P5 NDE

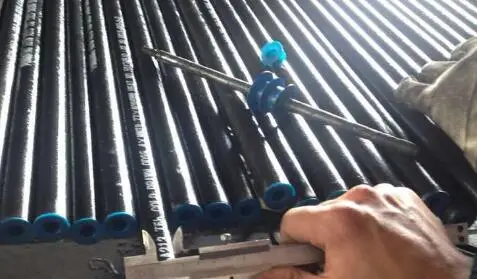

ASTM A335 P5 is the part of ASTM A335, The pipe shall be suitable for bending, flanging, and similar forming operations, and for fusion welding.

-

ASTM A335 Pipe (ASME S/A335, Chorme-Moly) is a seamless ferritic Alloy-Steel Pipe for high temperature service.

-

ASTM A213 T91 is the part of ASTM A213 Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, Heat-Exchanger Tubes.

-

ASTM A213 T9 is the part of ASTM A213 Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, Heat-Exchanger Tubes.

-

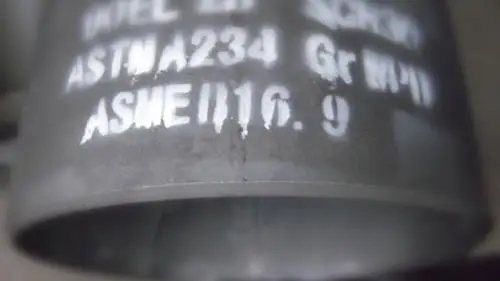

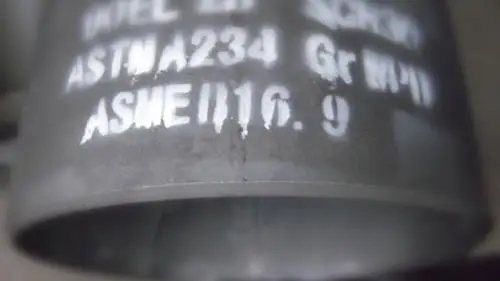

Welded pipe fittings are made as per ASME spec B16.9. ASME B16.9 covers factory made wrought steel butwelding fittings in sizes 1/2" to 48". This standard however does not cover low pressure corrosion resistant buttwelding fittings.

A234 WPB is the most common material used for carbon steel butt welded fittings.

-

ASTM A234 WPB is the Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service.

-

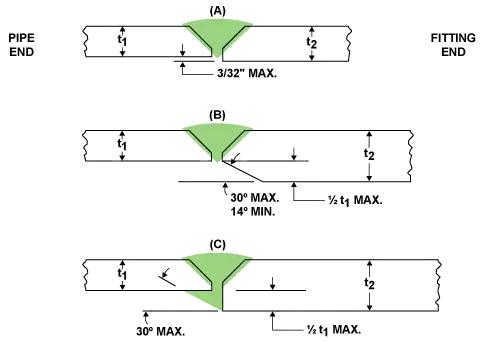

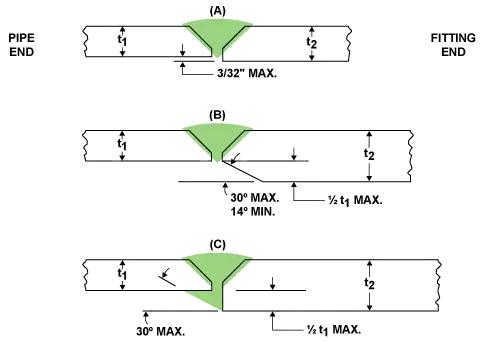

In the behavior, we make beveling after shot blasting, bevel ends are fully machined by advanced equipment Double Beveling Machine ensure the height, length, thickness, O.D. and I.D. are all qualified.

-

ANSI/ASME B16.25 Standard covers the preparation of butt welding ends of piping components to be joined into a piping system by welding.

-

MSS SP-97 Standard Practice covers essential dimensions, finish, tolerances, testing, marking, material, and minimum strength requirements for 90 degree integrally reinforced forged branch outlet fittings of buttwelding, socket welding, and threaded types. Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded, and Buttwelding Ends. Fittings manufactured to this Standard Practice are designed to make a fully reinforced branch connection in accordance with applicable piping code requirements, when attached, at an opening in a run pipe by means of a full penetration weld.

-

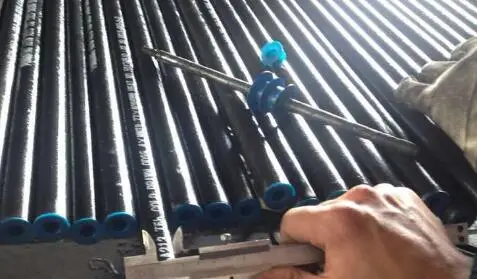

The most common non distructive tests (NDT) for pipe fittings:

-

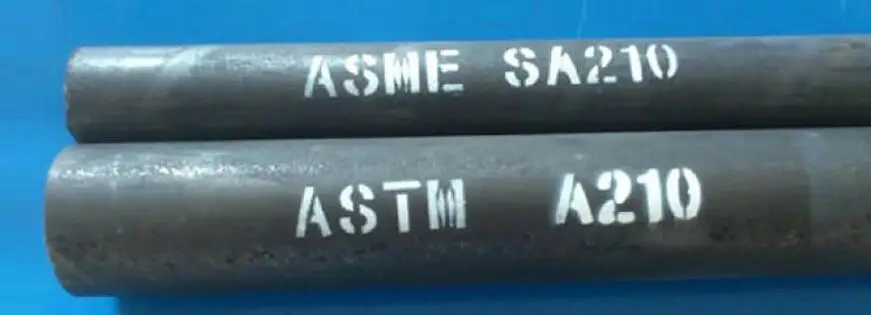

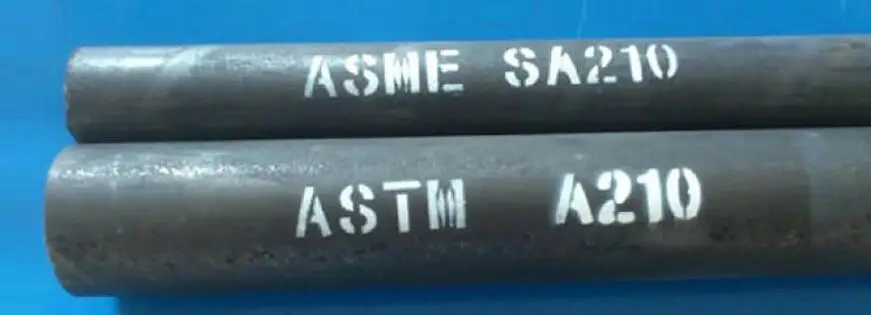

ASTM A210 is the standard covers seamless medium-carbon steel boiler and superheater tubes. Seamless medium carbon steel pipe for boiler tube and boiler flue pipe, including a minimum wall thickness of the security side, the dome and the support tube and superheater tubes.

-

DIN 2391 standard specifies the Seamless steel tubes used forMechanical and Automobile.

-

EN 10305 european standard specifies the technical delivery conditions for seamless cold drawn steel pipe of circular cross section used in hyhydraulic and pneumatic power systems.

-

ASTM A333 Grade 6 seamless pipes are applicated for low temperature service.

-

Wear-resistant alloy steel pipe as the base, lined with ultra-wear-resistant alloy, through the centrifugal casting, metallurgy combined to form a solid.

-

The rare earth alloy wear- esistant pipe is used for pneumatic, pump slurry, etc. Rare earth alloy wear resistant pipe has the characteristics of fast velocity and high flow rate. The conveying medium temporarily continues to produce impact on the pipe wall, wear, corrosion and so on, which causes the pipe to become tired and gradually wear out.

-

ASTM A335 P22 is the part of ASTM A335. ASTM A335 P22 alloy steel pipe shall be suitable for bending, flanging, and similar forming operations, and for fusion welding.

-

ASTM A335 P9 Alloy steel pipe apply to petroleum, chemical industry, electric power, boiler, high temperature resistant, low temperature resistant, corrosion resistant.

-

ASTM A213 T5 is the part of ASTM A213 Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, Heat-Exchanger Tubes.

-

LSAW (Longitudinally Submerged Arc Welded Steel pipes) in leaflets plate as raw material, the steel plate in the mold or molding machine pressure (volume) into using double-sided submerged arc welding and flaring from production.

-

The developing trend of LSAW steel pipe in the future: