-

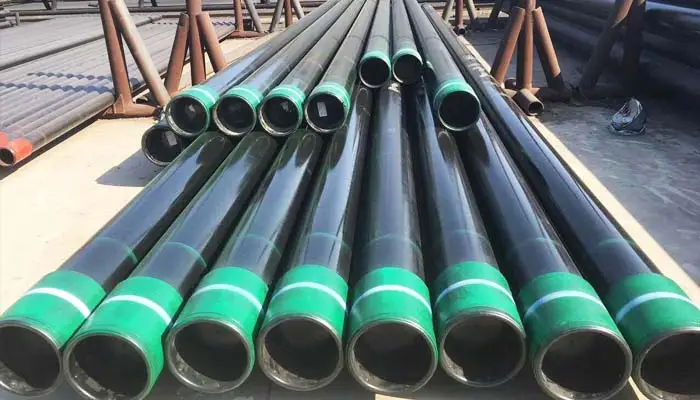

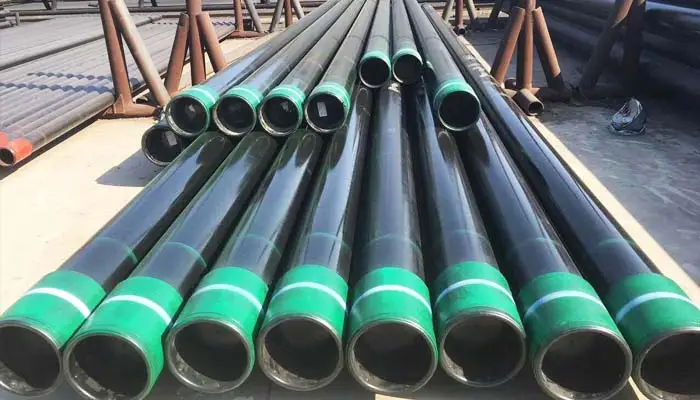

The invention provides a protective coating for oil pipes and wellheads and downhole equipment used in oil and gas drilling, oil recovery and transportation.

-

High-quality resources are tight and the price is high. Some mines have increased mine use, mine sales are better, traders are more active, and small and medium-sized mines are starting to improve slightly.

-

Q345 channel steel price market traditional sales season, and because of the "golden nine" market failure, the market will habitually think that the delay of the peak season, may eventually fall to October, so before the National Day, the market for " The Silver Ten” peak season still has high expectations, and after the steel price has been consolidated for more than a month, there are conditions for a rebound.

-

The steel market continued its rebound last week. In addition to the weak and weak market, other major varieties of construction steel continued to rise.

-

The application of galvanized flat steel has also expanded correspondingly with the development of industry and agriculture. Therefore, the enterprises engaged in the production of galvanized flat steel in China are also required to have higher requirements for the galvanized flat steel. It is also because of the high new reference price of galvanized flat steel, so the production and process requirements are also very high, so the application range and type of flat steel is also very rich. So what is the difference between galvanized flat steel and round steel?

-

Structural performance comparison of seamless steel tubes. Carbon structural steel pipe: This kind of structural steel pipe is generally smelted by converter or open hearth furnace. Its main raw material is molten iron and scrap steel. The content of sulfur and phosphorus in steel is higher than that of high quality carbon structural steel pipe. Generally, sulfur is ≤0.050% and phosphorus is ≤0.045%.

-

Skin turning of billets

The steel billet is a process for removing the surface defects and scale of the round billet and processing the specified outer diameter and a certain surface finish. The turning amount and turning accuracy are determined by the diameter of the billet and the type of steel. The amount of turning is shown in Table 4-2. The amount of turning varies according to the conditions of each factory, and is roughly in the range of 3.5-15 mm. The turning amount increases as the diameter of the billet increases. Stainless steel has more surface defects than ordinary carbon steel and low alloy steel, and its turning amount is also larger.

-

The cut steel pipe is inspected according to technical requirements. The inspection includes checking the size and bending of each pipe and the quality of the inner and outer surfaces of the pipe, and sampling the mechanics and process performance, but the inspection requires sampling. The inspection of the geometrical dimensions and bending of the steel pipe can be carried out on the inspection table, or it can be continuously detected by an automatic size detecting device such as laser caliper, thickness measurement, and length measuring instrument.

-

Features of cold drawn precision steel pipe

-

The current cost of capital is down. Compared with the cost of capital that was priced at 1-2 a month last year, the borrowing costs of traders have now declined. Although the financial pressure has improved, the current economic outlook is not optimistic, and the seamless pipe in East China ,Small-diameter seamless steel pipes and seamless steel pipes are at a low level.

-

Stainless steel seamless pipe product features:

-

20# cold drawn seamless pipe spot resource specifications :

194*20

325*14

-

Some experts pointed out that 16Mn seamless steel pipe China faces unprecedented problems in environmental issues.

-

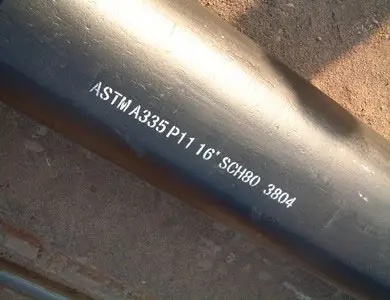

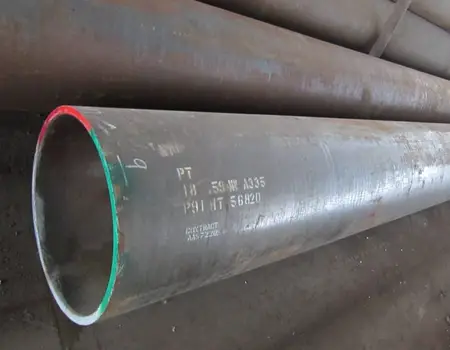

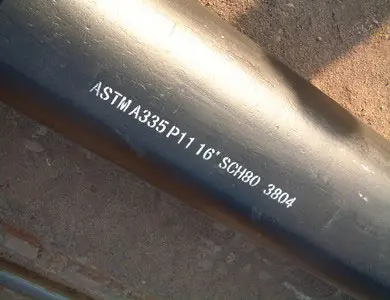

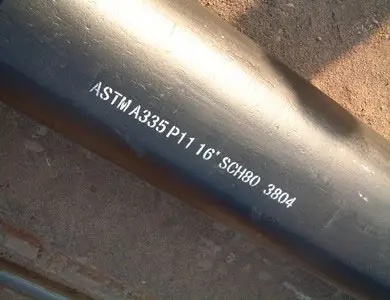

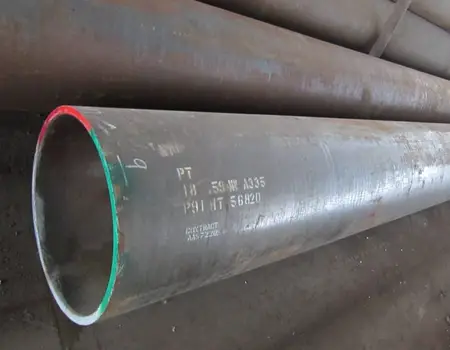

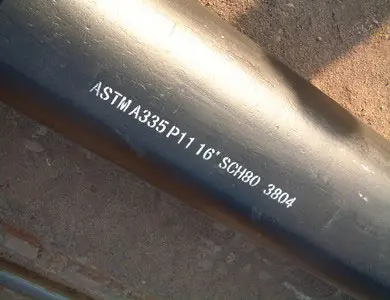

The high-pressure boiler tube is a kind of boiler tube. The high-pressure boiler tube is mainly used for manufacturing the superheater tube, the reheater tube, the air guiding tube and the main steam tube of the high pressure and ultra high pressure boiler. Belonging seamless steel tubes categories.

-

Thick-walled seamless steel pipeStructural tube GB />The reliability of several non-destructive testing methods for magnetic flux leakage, eddy current, ultrasonic and electromagnetic ultrasonic used in flaw detection is discussed. It can be seen from the comparison of the reliability of the above methods that electromagnetic ultrasonic method has advantages that are incomparable to other non-destructive testing methods. And broad application prospects.

-

Demand for steel in the domestic market is weak. At the same time, the growth rate of the main steel industry continued to decline. Steel production adhered to a high level, and the steel market still showed a situation of oversupply, so steel prices continued to fall in May.

-

The steel market last week was running at 4,300 yuan / ton, depending on the variety. A slight rebound in the third consecutive day, a half weeks after the 20th seamless steel pipe but still slightly lower than the previous week.

-

Structure with a seamless sizes of

Name Value

-

We often say that the use of galvanized pipes and galvanized pipes is also the type of iron pipe used for gas and heating. It is also a galvanized pipe.

-

Class-based Class I Ⅱ Ⅲ level

design pressure / MPa design temperature / ℃ Design pressure / MPa design temperature / ℃ Design pressure / MPa design temperature / ℃

> ≤

steam and hot oil 1.6 300 O. 7~1.6 170~300 0.7 170

fuel 1.6 150 O. 7 to 1.6 60 to 150 O. 7 60

other media 4. O 300 1.6~4. O 200~300 1.6 200

-

ABS alloy tube and special cold-melt adhesive are one of them. ABS alloy tube is widely used in building water supply and central air-conditioning. It is especially used in building water supply riser and central air-conditioning pipe. It can also be used to make automobile exterior parts. Such as car wheel covers, mirror housings, taillight covers, etc. PC/ABS has good formability and can process large parts of automobiles, such as car fenders.