-

ERW (Electric Resistance Welded) steel pipes are made from steel coils or steel plates and the weld seam runs parallel to the pipe. They are commonly applied to transport oil, natural gas and other vapor-liquid objects, and can meet various requirements of high and low pressure. This article will introduce in detail the quality evaluation process of ERW steel pipes. Read on to learn more.

-

When welded steel pipe is manufactured, a steel plate or strip is bent and subsequently welded into either a circular, traditional pipe shape or a square shape, resulting in a seam on its body. Today, we will introduce in detail GB standards for welded steel pipes.

-

When welded steel pipe is manufactured, a steel plate or strip is bent and subsequently welded into either a circular, traditional pipe shape or a square shape, resulting in a seam on its body. Today, we will introduce in detail GB standards for welded steel pipes.

-

API (American Petroleum Institute) tubing is used in the oil and gas industry for various applications, primarily in the production and transportation of oil and gas from wellheads to processing facilities. These tubes are an integral part of the downhole equipment in oil and gas wells. The manufacturing process and types of API tubing can vary depending on the specific requirements of the well and the conditions it will operate under.

-

Duplex steel is made up of two distinct microstructures: ferrite and austenite, which makes it more difficult to weld than other types of stainless steel. This article provides a comprehensive guide to welding duplex stainless steel pipe so that you can make the most use of your work.

-

Straight seam steel pipe is a type of welded steel pipe. According to the production process, straight seam steel pipes can be divided into high-frequency straight seam steel pipes and submerged arc welded straight seam steel pipes. Submerged arc welded straight seam steel pipes are divided into UOE, RBE and JCOE steel pipes according to different forming methods.

-

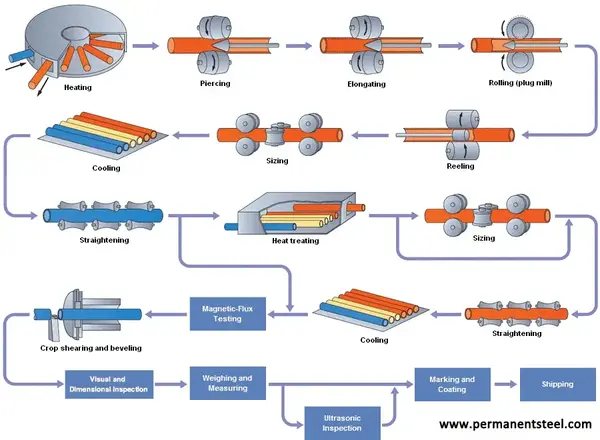

Double-sided submerged arc welding straight seam steel pipe (LSAW) production process

-

Standard general size of stainless steel plate thickness

-

The benefits of using thin-walled stainless steel pipes

-

Classification and implementation standards of steel pipes

-

Characteristics of steel pipes

-

tubos de acero inoxidable

-

What are the types and uses of stainless steel pipes?

-

Stainless steel pipe is a kind of hollow long round steel, which is mainly used in industrial transportation pipelines and mechanical structural components such as petroleum, chemical industry, medical treatment, food, light industry, mechanical instrument and so on. In addition, when the bending and torsional strength are the same, the weight is lighter, so it is also widely used in the manufacture of mechanical parts and engineering structures. It is also commonly used to produce various conventional weapons, barrels, shells, etc.

-

316L stainless steel pipe is a kind of hollow long round steel, which is mainly used in industrial transportation pipelines such as petroleum, chemical industry, medical treatment, food, light industry, mechanical instrument, etc., as well as mechanical structural components. In addition, when the bending and torsional strength are the same, the weight is lighter, so it is also widely used in the manufacture of mechanical parts and engineering structures. It is also commonly used to produce various conventional weapons, barrels, shells, etc.

-

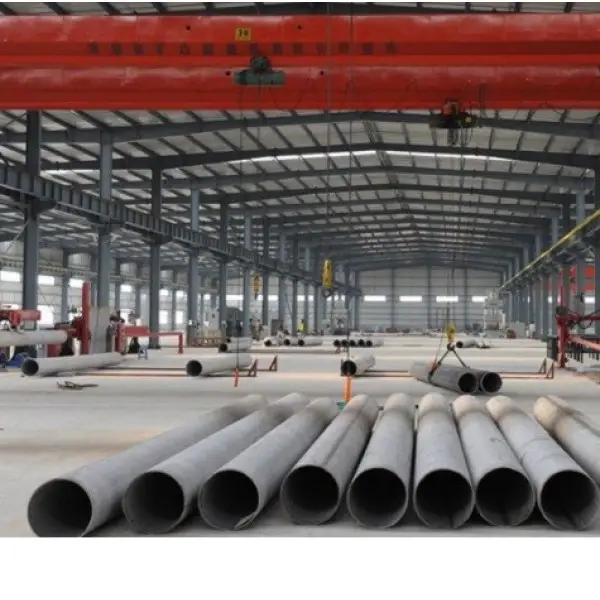

seamless steel pipe

-

What are the classifications of stainless steel

-

Oil casing knowledge

-

The difference between hot-dip galvanized steel pipe and cold-dip galvanized steel pipe

-

steel pipe china

-

What is a titanium alloy steel pipe