-

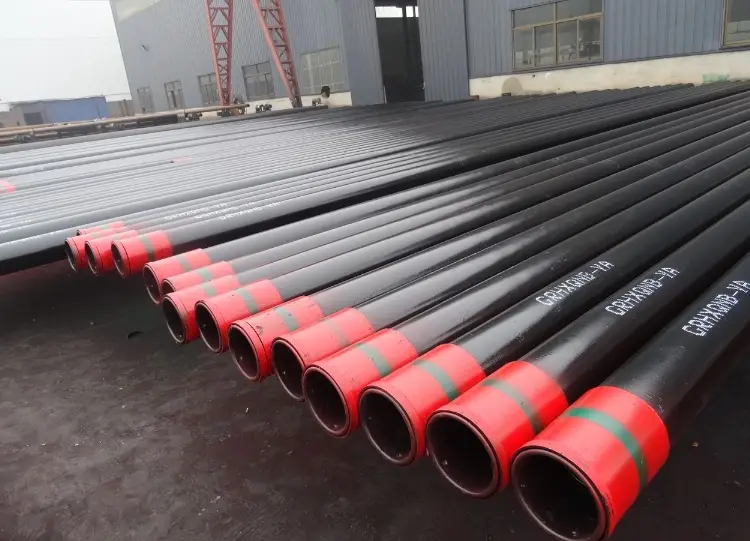

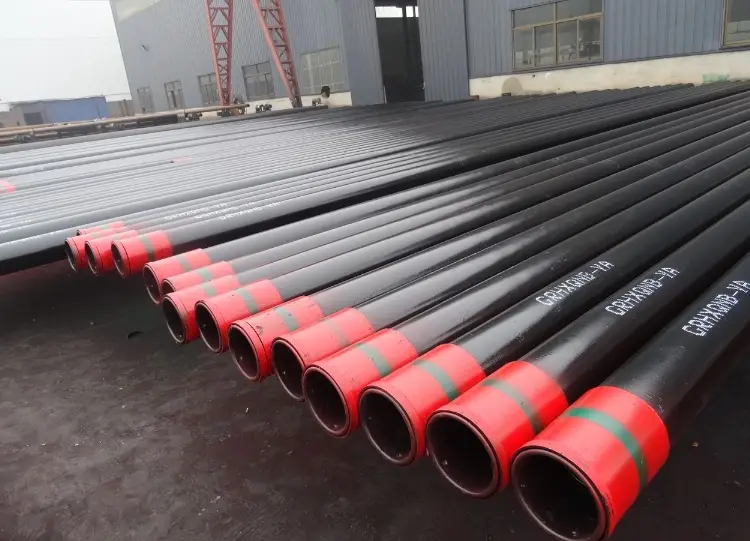

Electric Resistance Welded (ERW) oil casing is widely used in the oil and gas industry, primarily for the structural support of oil, gas, and water wells during drilling and completion operations. This article will briefly introduce ERW oil casing application and market analysis.

-

Oil casing pipes play a critical role in supporting the walls of oil, gas, and water wells, ensuring their stability after drilling and completion. They are essential for the normal operation of oil and gas wells. However, issues such as improper selection, poor quality, or mishandling during transportation, storage, and use can lead to casing damage. This, in turn, can reduce production rates or even cause wells to be abandoned, resulting in significant economic losses for oil and gas companies. So, how should one go about purchasing oil casing pipes?

-

Here's an overview of the rules for the thread of casing pipe.

-

Oil casing pipe is considered a premium product in the steel pipe industry, with a wide variety of specifications. There are 15 different outer diameter sizes, ranging from 114.3mm to 508mm. The steel grades are categorized into 11 types, including J55, K55, N80, L-80, P-110, C-90, C-95, and T-95. Various end connection types are available for oil casing pipes, such as STC, LC, BC, and VAM. The production and installation process of oil casing pipes involves a series of rigorous tests, which include the following.

-

The welding of oil casings involves complex processes where even slight mechanical failures or inconsistencies can lead to issues such as the formation of short joints. A short joint in oil casing welding typically occurs due to factors like internal mechanical malfunctions, such as roller or shaft eccentricity, excessive welding power, or misalignment. These problems disrupt the welding process, resulting in defects that compromise the overall quality of the weld. Understanding these factors and how they affect the welding process is critical for producing high-quality oil casing joints.

-

The appearance quality of casing pipes is critical for ensuring their proper function and durability in demanding environments. The requirements focus on both the dimensions and surface conditions of the casing, ensuring safety, reliability, and longevity in use.

-

Here's an overview of the typical installation method and steps of oil well casing.

-

Offshore oil and gas exploitation presents a unique set of challenges due to the harsh conditions of the marine environment, including extreme temperatures, high pressure, and constant exposure to corrosive elements. As a result, the steel pipes used in these operations must meet stringent requirements to ensure safety, reliability, and long-term durability.

-

The API 5CT oil casing within an oil well must endure various stresses during its operation, and understanding these stresses is critical to ensuring the casing remains intact without deformation or cracking. To achieve this, the casing material and design must have sufficient strength to resist external forces, making stress analysis a key part of the process.

-

In recent years, a well-logging survey of a particular block project revealed that 45 wells, accounting for approximately 28.5% of the total, exhibited varying degrees of casing damage. This issue has shown a significant upward trend. The primary forms of damage include casing bending, shrinkage, faulting, rupture, and corrosion perforation, with casing shrinkage deformation and faulting being the most prevalent. The overall trend indicates that wells with casing damage tend to have a short production lifespan, and the damage typically occurs at greater depths.

-

Drill pipes are essential tools in drilling and oil production operations within the oil and gas industry. They are required to endure significant pressure and harsh working conditions. The ability of a drill pipe to withstand pressure is primarily determined by its material properties, manufacturing quality, design, and compliance with technical standards such as those set by the American Petroleum Institute (API) or the International Organization for Standardization (ISO).

-

USI employs a meticulous quality assurance framework to meticulously scrutinize raw materials and conduct thorough product testing throughout the manufacturing process. This approach ensures that every tube adheres to stringent quality benchmarks and is deemed fully compliant before leaving the factory. The quality control protocol encompasses several key stages.

-

To ensure the consistent performance of heat-treated products during the swift induction heating process, a series of strategic actions should be implemented on the production line.

-

On site, downhole operations should be performed in accordance with API RP 5C1. Prior to use, casing pipes must be prepared and inspected. Thread grease and pliers with a torque control system should comply with API BUL 5A2. Specific operational requirements are as follows.

-

The production of casing pipes in an oil casing plant involves several critical steps to ensure the final product meets the required specifications and quality standards. Here is an overview of the process of casing pipe in plant.

-

P110 casing pipes are crucial in well operations, serving several key functions that ensure the stability and efficiency of oil and gas extraction. Here's an in-depth look at their role and the best practices for their maintenance and repair.

-

Oil casing pipes are used to support the walls of oil and gas wells, ensuring the proper functioning of the well during drilling and after completion. There are two primary types of steel pipes used for petroleum casing: Seamless Casing and ERW Casing. Here’s a detailed comparison between them.

-

The manufacturing technology for casing and tubing cores involves intricate processes designed to ensure superior mechanical properties and corrosion resistance, essential for their use in harsh environments. This document outlines the key technologies and methods employed in the production of high-performance casing and tubing cores, emphasizing the importance of chemical composition, processing techniques, heat treatment, welding methods, and innovative manufacturing technologies. Read on to learn more.

-

Drill pipes are essential tools in oil drilling operations, with their diameter being a critical parameter affecting drilling efficiency and load-bearing capacity. The standards for drill pipe diameters include both inch and metric measurements.This article will briefly introduce drill pipe diameter and model selection.

-

OCTG casing pipes come in various materials, and the choice depends on the application scenario and specific requirements. Below are some common casing materials along with their characteristics.

-

High-performance oil well casing is designed to withstand the extreme conditions found in oil and gas exploration and production. This specialized casing ensures the integrity and safety of the wellbore, providing a critical barrier against the high pressures, temperatures, and corrosive environments typically encountered in oil wells.