-

The difference between hot-dip galvanized steel pipe and cold-dip galvanized steel pipe

-

steel pipe china

-

What is a titanium alloy steel pipe

-

what are the advantages of stainless steel pipes

-

Seamless characteristics of ERW steel pipe

-

What is the difference between spiral pipe and other steel pipes?

-

The seamless steel pipe is divided into cold drawn and hot rolled, but the surface has not been treated.

There are several types of seamless steel pipes. They are related to its material and implementation standards.

-

Spiral welded pipe hydrostatic test pressure

-

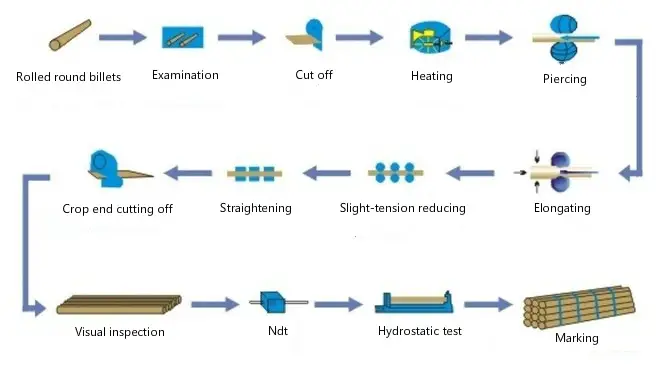

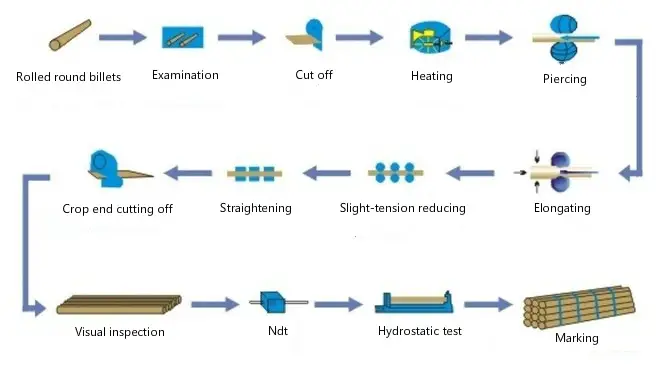

Production process of seamless steel pipe

-

Comparison of spiral steel pipe specifications

-

ERW stands for resistance welding. Resistance welding has the characteristics of high production efficiency, low cost, material saving, and easy automation. Therefore, it is widely used in aviation, aerospace, energy, electronics, automobiles, light industry and other industrial sectors. It is one of the important welding processes.

-

Large diameter hot rolled seamless pipe

-

Introduction of commonly used steel pipes-steel-plastic composite pipes, large-diameter seamless steel pipes

-

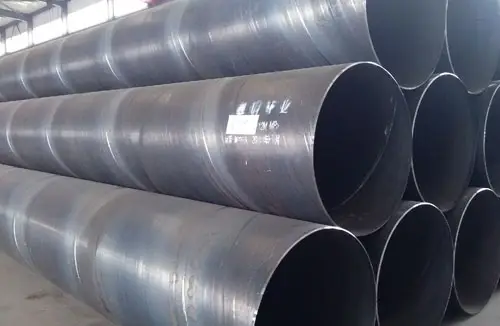

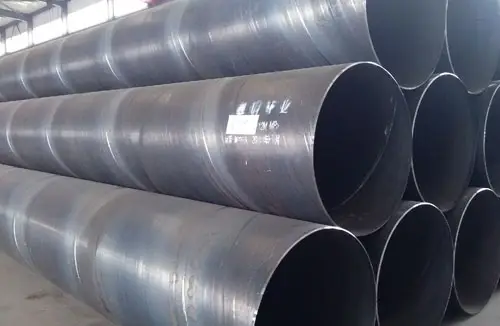

Submerged arc welding spiral steel pipe

-

Steel welded pipe

-

The difference between seamless steel pipe and ordinary steel pipe

-

Knowledge summary of seamless steel pipes for tubing materials

-

Los tubos de revestimiento para petróleo se consideran un producto de primera calidad en la industria de los tubos de acero, con una amplia variedad de especificaciones. Hay 15 tamaños de diámetro exterior diferentes, que van desde 114,3 mm hasta 508 mm. Los grados de acero se clasifican en 11 tipos, incluidos J55, K55, N80, L-80, P-110, C-90, C-95 y T-95. Hay varios tipos de conexión final disponibles para los tubos de revestimiento para petróleo, como STC, LC, BC y VAM. El proceso de producción e instalación de los tubos de revestimiento para petróleo implica una serie de pruebas rigurosas, que incluyen las siguientes.

-

The tubing in the oil casing is a pipeline that transports crude oil and natural gas from the oil and gas layer to the surface after the drilling is completed.

-

Stainless steel welded pipe standard

-

Steel-plastic composite pipe, large-diameter coated steel pipe