-

ASTM A335 specification covers seamless ferritic alloy-steel pipe for high-temperature service. The pipe shall be suitable for bending, flanging, and similar forming operations, and for fusion welding. Grade P2 and P12 steel pipes shall be made by coarse-grain melting practice. The steel material shall conform to chemical composition, tensile property, and hardness requirements. Each length of pipe shall be subjected to the hydrostatic test. Also, each pipe shall be examined by a non-destructive examination method in accordance to the required practices. The range of pipe sizes that may be examined by each method shall be subjected to the limitations in the scope of the respective practices. The different mechanical test requirements for pipes, namely, transverse or longitudinal tension test, flattening test, and hardness or bend test are presented.

-

-

Seamless steel pipe is a high-strength, high-pressure steel pipe that is often used in pipeline systems for transporting gases, liquids, solids and other media. Seamless steel pipes are produced through cold/hot rolling and drawing processes. They have smooth surfaces, smooth inner and outer walls, high dimensional accuracy, and good corrosion resistance and mechanical properties. Therefore, seamless steel pipes are indispensable in some situations where high pressure and high flow are required.

-

Square steel pipe refers to a steel pipe with a square or rectangular cross-section. It can be divided into many types according to different manufacturing processes and materials. Common square tube steels include hot-rolled square tubes, cold-rolled square tubes, galvanized square tubes, etc. These different types of square tube steel have different physical properties and uses, but all offer excellent strength and corrosion resistance.

-

ASTM A179 Cold Drawn Seamless Carbon Steel Tube are manufactured in cold-drawn seamless, material in low carbon steel, sizes up to 3”, for heat exchanger and condenser.

-

In recent years, with the rapid development of the automobile industry, precision seamless steel pipes, as a high-quality steel pipe material, have also been widely used in this industry. This article will elaborate on the application and development of precision seamless steel pipes in the automotive industry.

-

Steel beams and profiled steel plates are both steel products, the difference lies in their different production processes and uses. Steel beam is a kind of steel with I-shaped cross-section, which is widely used in the fields of construction and bridge. Pressure plate is a kind of steel plate after pressing and molding, used in steel structure, industrial equipment and warehouses and other fields.

-

The classification of pipeline pressure levels refers to dividing the pipeline pressure levels into high pressure, medium pressure, low pressure and other levels according to the pressure that the pipeline must bear during work.

-

ASTM A213 Alloy Tubes are a series of seamless ferritic and austenitic alloy-steel tubes that are designed for use in high-temperature and corrosive environments.

-

This article will provide a detailed introduction and analysis of X52QO seamless steel pipe from the aspects of production process, performance characteristics, application fields and market prospects of seamless steel pipe.

-

ASTM A53 is a carbon steel alloy that can be used as structural steel or for low pressure piping. ASTM A53 (ASME SA53) carbon steel pipe is a specification covering seamless, welded black and hot-dip galvanized steel pipe from NPS 1/8 "to NPS 26. A53 is suitable for pressure and mechanical applications, as well as for general use in steam, water, gas and air lines.

-

Quality control and testing are crucial aspects of ensuring the reliability and performance of welded pipes in various industries. From manufacturing to installation, a rigorous quality control process helps identify any defects or inconsistencies in welded pipes, preventing potential failures and ensuring compliance with industry standards. In this article, we will explore the importance of quality control and testing in the production of welded pipes, highlighting key methods, standards, and procedures used in the industry.

-

ASTM A106/ASME SA106 is the standard specification for seamless carbon steel pipe used for high-temperature services. It includes three grades: A, B, and C, with Grade B being commonly used. This type of pipe finds applications in various industries, including pipeline systems for oil and gas, water, and mineral slurry transmission. It is also used in boiler systems and for construction and structural purposes.

-

The purpose of this specification is to provide a guide for the production of transport pipes. Products made under API 5L optics carry gas, oil, and water in the natural gas and oil industry.

-

Welded steel DN300 is generally divided into two types straight welded black pipe and spiral welded black pipe. Using spiral coil technology and high-frequency welding to create the most durable steel pipe products.

-

ASTMA252Gr3 spiral steel pipe is one of the commonly used types of steel pipe, such steel pipe has a wide range of applications, the understanding and mastery of its relevant parameters for engineering design and construction is crucial.

-

Black iron pipe is processed with iron as the main raw material, and the surface has a black oxidized layer, hence the name. The main component of black iron pipe is iron, with lower carbon content, lower hardness and easy to rust. The main components of carbon steel pipe are carbon and iron, of which the carbon content is between 0.08% and 0.25%, high hardness, more solid and wear-resistant than black iron pipe.

-

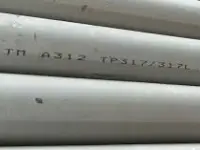

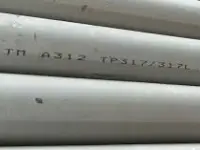

Material Standard:ASTM A312

Grade No.:TP317L

Type:seamless & Welded tubes

End:Beveled End,Plain End

-

X46Q seamless steel pipe is a high-strength, high-toughness steel pipe material that is widely used in petroleum, natural gas, chemical industry, electric power and other industrial fields. Its emergence has provided strong support for the development of modern industry and has become an indispensable and important material in the industrial field.

-

Today, United Steel will discuss about the key difference between Seamless and ERW Stainless Steel Pipe

-

Galvanized steel pipe usually means that a layer of zinc is coated on the surface of the steel pipe to prevent it from rusting, thus improving its service life. So, does galvanized steel pipe have a shelf life?