-

The reason of the cold crack is the process of the hardenability of the welding material which is easy to be cooled by the people when being welded. The cooling speed of the welding is too late for the residual hydrogen in the weld to escape. The molecular hydrogen of a hydrogen atom Of the metal pores cause a lot of pressure, so that the pressure of local metal cold bending cracks; focus on hydrogen embrittlement and hardening of the welding stress and tensile stress analysis at the same time prone to the formation of cold cracks.

-

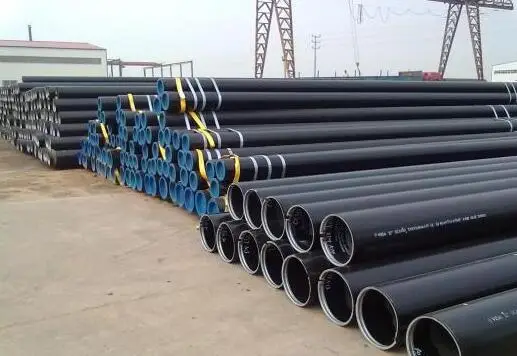

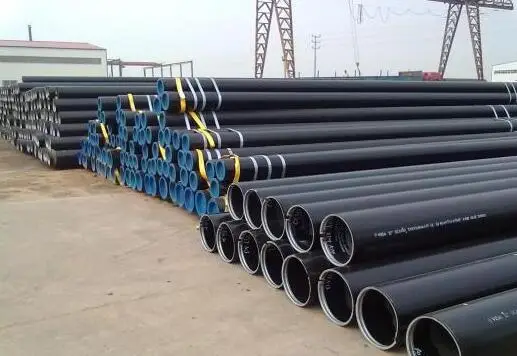

Seamless steel pipe perforated hole production of steel. Welded steel pipe into a barrel and then welded. According to its production of seamless steel pipe and welded pipe method is divided into two. Seamless steel pipe using high-quality carbon steel or alloy steel, hot-rolled, cold-rolled (pull) points. Welded steel rolled into the tube plate, weld or spiral seam welding, in the manufacturing method, is divided into low pressure fluid welded steel pipe, spiral welded steel pipe, straight seam welded pipe, welded pipe. Seamless steel pipe can be used for a variety of liquids, gas pipelines. Welded pipe can be used for water pipes, gas pipes, heating pipes. Seamless steel pipe for important applications, such as pipes, barrels and other uniform, high pressure. General use of high-quality steel, alloy steel or even. The general purpose of the general use of steel compression steel, such as water pipes, gas pipes and so on

-

To achieve steel pipe manufacturing machine:

Combined with specially designed equipment 1600mt bending machine, multi-roll plate bending machine, welding equipment, internal and external girth welding, size setting machine, solution annealing furnace and a series of other related machinery, is used to manufacture key applications Such as oil refining, fertilizer, LNG terminal pipelines, transnational pipelines.

-

Preheating is a process, or in the overall welding before the weldment weld area is hot. Particularly good welding high strength materials, work hardening tend to steel, thermal conductivity, thicker weldments, when the ambient temperature is too low, the weld zone often requires preheating before butt welding.

The purpose of preheating is to reduce the cooling rate of the welded joint and the preheating temperature. As can be seen from the table, preheating can reduce the cooling rate, but does not affect the time to stay at high temperatures, which is very desirable. Therefore, when the weld steel has a tendency to quench, the main process of reducing the cooling rate and reducing the tendency of quenching is to heat rather than increase the input of energy.

-

Low-carbon steel refers to steel containing less than 0.25% carbon, low strength, low hardness and softness. It includes most of ordinary carbon steel and high-quality carbon structural steel, most of which are not used for heat treatment in engineering structures, but also for some mechanical parts required for carburizing heat treatment and other wear. Low carbon steel annealed ferrite and pearlite strength and hardness, ductility and toughness are low. Therefore, cold forming performance is good, and cold forming methods such as crimping, bending and punching can be performed. This mild steel pipe weldability. Mild carbon steels with carbon contents ranging from 0.10 to 0.30% are easy to accept for a variety of processes such as forging, welding and cutting, commonly used in the manufacture of chains, rivets, bolts, shafts and more.

-

In the pipe from the top of the arc, from top to bottom all-position welding technology, welding speed method, weld appearance, good welding quality, welding materials can be saved, reducing labor intensity is a common hand can not be more widely than now Applied to large-diameter long-distance pipe welding in the lower welding of large-diameter thin-walled tube construction of all power status has a certain promotional value.

-

Black steel pipe is made from steel that has not been galvanised and is called black because of the dark coloured iron-oxide scale formed on its surface. it is used in the oil and petroleum industries to transport large quantities of oil and for the distribution of gas into homes. It is used in transporting water and gas in both rural and urban areas as we as for conduits that protect electrical wiring. It is also used for delivering high pressure steam and air.

-

The use of epoxy powder coating in foreign countries have 30 years of history, due to a wide range of sources of raw materials, production methods are simple, cheap, good performance, do not pollute the environment, long life, is a good anti-corrosion coating. Petroleum Institute of Building Technology Corrosion in the oil pipeline in China, the successful development of the epoxy powder to fill the domestic pipeline anti-corrosion coating anti-corrosion paint blank. The coating has excellent chemical resistance, good mechanical properties, high electrical insulation properties and good toughness. Corrosion test Predict the life of the coating, intact storage of paint, oil, gas, water pipes, life expectancy of up to 15 years; make sewage and mixed water pipe coating life of up to 5-7 years. The pipe industry's construction methods, the most widely used static thermal spraying method. According to the data, the coating requirements for epoxy powder coatings are also different due to the thickness of the media delivered. Domestic oil, gas, water, sewage and other corrosive medium containing corrosion pipe is the best thick coating. Electrostatic spraying thick coating, spray thickness up to 250 ~ 350 / a, the maximum thickness of up to 500, ~ (n) electrostatic powder moraine coating is a surface treatment of solid powder, it has the equipment is simple, easy to operate, The process is simple, not subject to the size of the workpiece and other advantages.

-

According to the spiral submerged arc welded pipe corrosion mechanism, has put forward a variety of protective measures, this protection can basically be divided into the following types:

-

In the long-distance pipeline construction, the pipeline accounts for a large proportion, generally 35% to 40% of the total investment pipeline project management. How to choose a reasonable price, excellent performance of the pipeline is particularly important, a reasonable choice of pipeline construction investment savings, the construction of the pipeline system and safe operation has a very important impact. Natural gas pipe straight seam high-frequency resistance welded steel pipe, spiral submerged arc welded pipe, LSAW steel pipe.

-

The main difference between seamless steel pipe and welded pipe is the molding process. Generally welded steel pipe, such as water pipes, are usually bent and welded together by a flat plate, after which you can find a seam; the diameter is usually a spiral weld.

-

In the pipe from the top of the arc, from top to bottom all-position welding technology, welding speed method, weld appearance, good welding quality, welding materials can be saved, reducing labor intensity is a common hand can not be more widely than now Applied to large-diameter long-distance pipe welding in the lower welding of large-diameter thin-walled tube construction of all power status has a certain promotional value.

-

Welding method is under the conditions of welding materials, according to the design requirements of the welding components, and can meet the requirements of the scheduled service. The four factors are affected by the welding material, welding, the type of part and the usage requirements.

-

Steel pipe hardness and tensile strength

-

Effect of remanence on welding quality and its influence

Gas pipeline construction and repair welding operations, sometimes appear blowing phenomenon, affecting the welding process. The formation of a magnetic strike is due to the presence of metal residual magnetism in the pipe. Usually, the magnetic induction and remanence are divided into two processes. Magnetically-induced plants tend to produce tube links such as metal smelting, handling using electromagnetic cranes, tube parking in a strong magnetic field, non-destructive testing after magnetization, and placing the tube close to the power cord and so strongly. Magneto-electric welding often occurs during the process. When assembling and using the magnetic retainer, the fixture and the DC welding pipe are connected to each other. For example, a long contact is connected to a DC power cable, a bare wire section or a short-circuit pipe welding fixture.

-

3PE corrosion-resistant steel pipe buried pipe life is crucial, the same material, pipe buried in the ground for decades and some non-corrosive, leaks in a few years. Because they use different outer coating.

-

Classification and Production Methods of Welded Steel Pipe

-

Eddy current testing features are as follows:

Advantages of eddy current testing

1, When test, the coil does not require contact with the workpiece, but also without the coupling medium, so the detection speed.

-

The following hs code apply to all kinds of steel pipe products, such as seamless pipe, welded pipe(erw pipe, ssaw pipe, lsaw pipe), stainless steel pipe, pipe fittings, etc.

-

Steel pipes are ubiquitous and can be found in underground and residential walls, laboratories, and commercial and industrial structures. Pipes transport fluids, including water, natural gas, waste and air. There are three manufacturing methods for the production of steel pipes. The seamless steel pipe is produced by extrusion die. The welded steel pipe is produced by rolling the steel plate into the pipe and welding.

-

Due to the strong bending ability of carbon steel pipe factory, so in recent years, the stadium building roof truss, beam, column, the steel structure housing, with the development of steel structure manufacturing industry in the construction of more and more use of steel structure, household appliances, furniture, plumbing, HVAC, gas, transportation and agriculture equipment the manufacturing industry, coal, oil and gas exploitation of underground resources, gun, air and space rockets, artillery, missile etc.. Iron and steel can not be separated, so the development of the national economy on the pipeline is closely related to the living standard of the people.