-

Black pipe and galvanized steel pipe are the two most commonly used pipes for transporting liquids and gases. They have a few similarities, many confuse one with another. What is the main difference between black and galvanized steel? Black steel pipe and galvanized pipe is made of steel, but galvanized pipe with zinc coating, and black pipe is not galvanized, galvanized pipe is more expensive and more durable. In transportation, black steel pipe is more corrosive than galvanized pipe, so it is more suitable for conveying gas, while galvanized pipe is more suitable for conveying water than gas.

-

1, according to CS steel production methods for classification.

(1) seamless steel pipe, including hot-rolled tubes, cold-rolled tubes, cold drawn tubes, extruded tubes.

(2) welded steel pipe

-

Spiral pipe factory should be carried out before the mechanical properties test and flattening test, and the flaring test, to meet the standards. Spiral pipe quality inspection methods are as follows:

1, on the surface, that is visual inspection. Visual inspection of welded joints is a straightforward process, but widely used test methods are an important part of product testing with major defects and variations on the surface of the welded dimension. Usually with the naked eye, using standard models, gauges and test tools, such as magnifying glass. If the weld surface defects, weld defects may exist inside.

-

Spiral submerged arc welded pipe often appear in the production and use of some quality problems affect the normal use, in some areas, the need for spiral welded pipe to determine the quality, according to certain methods and performance tests, can play a significant role in the actual use , Then how to identify fake and shoddy spiral pipe method: appearance often ma face phenomenon. In general, the overall ratio is better, mainly considering the problem of cumulative error and probability theory. Please add some of the above, if insufficient, we welcome everyone to discuss the knowledge of steel pipe, continuous improvement of exchange. Pock is due to severe wear groove spiral welded pipe irregular irregularities caused by defects. Because fake and inferior spiral welded pipe manufacturers have to pursue profits, rolling trough the most often exceeded. The surface is very easy to produce scars.

-

Cold drawing unit (cold rolling machine and cold drawing machine) Cold rolling, cold drawing or cold rolling and cold drawing combination of cold processing technology for the production of pipe assembly equipment portfolio. It is hot-rolled pipe or steel deep processing unit.

-

In general, the hydraulic (pneumatic) part is assumed to be uniform, continuous and isotropic when planning the use of mechanical properties, which is safe by analysis and sometimes has unexpected consequences for the spiral steel pipe Fault cracking attack.

-

The daily use of seamless steel pipe plant is due to a large number of post-processing procedures caused by, in short, this happens, the specific heat return process, the steel is heated to 750 degrees, the heat for some time, slowly cooled to 500 degrees , The final cooling is called the ball in the annealing air. The purpose is to reduce the hardness of steel, improve cutting performance, mainly for high carbon steel. Its main purpose is to refine the organization, standardize seamless steel pipe, improve the performance of steel, close to the balance of the organization.

-

The data show that after two days of aging treatment dissolved in the same level of mechanical properties. However, the number of induction heating steel, arc furnace, casing metallurgy quality is far lower than the vacuum induction furnace steel. This induction-heated solution process compensates for the steel gap and shows the benefits of induction heating on the spoon.

-

First, a reasonable choice. Precision messy mold materials should be selected Good micro-deformation of the hard alloy segregation mold should be reasonable casting and heat treatment quenching and tempering, the large double-casting castings can not be heat-treated casting. A reasonable choice of heating temperature control heating rate, the messy precision molds can be slow heating, preheating and other methods to reduce the mold heated and heated uniform deformation.

-

Thick-walled LSAW steel pipe rust-proof oil to deal with, we must first understand and rust-proof oil characteristics of varieties, and their results. So this time in the purchase of goods can not be out of balance, directly save time. Here let us introduce the advantages and varieties of vertical side crepe oil Xiao side wall.

-

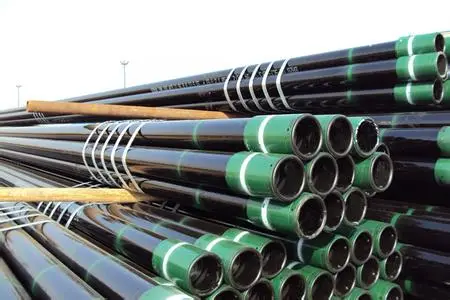

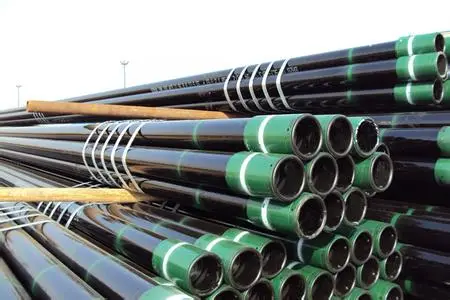

Common defects and defects of oil casing thread

1, black top oil casing thread

-

Seamless steel pipe by different cross-sectional shapes can be divided into tubular and special-shaped tube. Because of the same conditions on the circumference, the maximum area of the tube can accommodate more fluid. In addition, the circular cross-section withstands internal or external radial pressure, force uniformity. Therefore, the vast majority of pipelines are pipelines. However, there are some restrictions on tubes. Under such conditions as plane bending, square tubes such as square and large seamless steel tubes, some agricultural machinery skeletons, steel-wood furniture, popular square and rectangular tubes, etc. Mechanical properties of different seamless steel tubes.

-

First of all, 304 stainless steel seamless pipe thicker, more economical and practical, the thinner the wall thickness, processing costs will be substantially increased;

Second, 304 stainless steel seamless pipe technology to determine its limitations, the general seamless low accuracy: the uneven thickness of the inner wall, low brightness inside the tube, the fixed length of the high cost, and the hole outside, black spots difficult to remove;

Third, 304 stainless steel seamless pipe testing and plastic processing must be offline. Therefore, it shows its superiority in high-pressure, high-strength mechanical structure.

-

304 seamless steel tube burst causes are as follows:

1.304 Seamless Polishing Flatness Insufficient to Deflect.

-

Sleeve in the production of prone to folding defects, affecting the improvement of product quality, need to be controlled.

-

Seamless steel pipe wall thickness control is the production of steel pipe difficult to improve the precision of seamless steel pipe wall thickness Production measures include the following aspects:

1, tube heating

-

Seamless thick-walled pipe uneven

1, in the seamless steel pipe perforation process, the extension coefficient is too large, the rolling speed is too high, smooth rolling.

-

Core Manufacturing Technology The core manufacturing technologies for casing and tubing are as follows:

-

For galvanized steel pipe production line has special requirements, especially in the production environment, a good environment can help us better production, improve production quality and production efficiency, especially galvanized steel, the need for a stable environment is even more so.

-

In order to understand the quality and quality of cement concrete and pipe wall of seamless concrete filled steel tubular pump, ultrasonic pulse method was used to inspect and identify the quality of the main concrete filled steel tube.

-

Spiral pipe (spiral submerged arc welded pipe) into a steel unit, multi-roll rolled strip gradually rolled up to form a gap opening pipe, squeeze roll reset adjustment, in 1 ~ 3mm, weld gap control and welding end of the rinse .

1. If the gap is too large, resulting in reduced proximity effect, lack of eddy current, poor weld crystallization, indirect fusion or cracking bad.

2. The gap is too small, resulting in increased proximity effect, excessive welding heat, causing the weld to rupture; weld or extrusion, the formation of pit after rolling, affecting the weld surface quality.