-

Galvanized steel surface coated with a layer of zinc is generally low carbon steel, galvanized layer is generally 20um thick. At 419 ° C, the melting point of zinc is about 908 ° C. During welding, zinc is melted into the liquid that floats on the surface of the cell or the root of the weld. Zinc is more soluble in iron and the zinc corrosion solution will enter the weld metal along the grain boundaries, forming a "low melting point of liquid metal embrittlement." At the same time, brittle intermetallics of zinc and iron may form, and these brittle phases, Tensile stress cracks in the weld metal plasticity decreased. If the weld, fillet weld is the most easy to penetrate the crack. When welding galvanized steel, the zinc layer oxidizes, melts, evaporates and even volatilizes white smoke and steam at the bevel surface and edges at the arc heat, easily causing the weld pores.

-

Hot galvanized is the addition of some auxiliary material to the molten zinc at a high temperature, and then attaching the zinc-dip bath metal structure to the metal member on the zinc layer. Hot-dip galvanizing with anti-corrosion ability, coating adhesion, good hardness and so on.

Cold galvanized is the use of the degreased workpiece electrolysis device, the pickling component is zinc salt solution, and connected to the cathode electrolysis device; zinc electrolysis device placed on the front of the connecting plate, the power supply is reversed, moving from the positive to negative direction current The use of it to deposit a layer of zinc on the workpiece.

-

galvanized zinc sheet appears on the surface, that is, those rough small particles do not polish, which not only affect the appearance of small particles, but also affect the use. This is because the bottom of the dregs is too agitated and the surface temperature of the galvanized sheet is too high because of the good affinity with the aluminum, aluminum and zinc in the zinc solution, except for the bottom ash float process Together, attached to the galvanized sheet surface. For example, the bottom ash is often treated to maintain the cleanliness of the galvanized steel. The temperature of the zinc-plating solution is not too high and is maintained at a suitable temperature of 440 to 450 degrees Celsius. Liquid zinc aluminum content is not high, maintained at about 0.1% is appropriate, but also pay attention to inventory will increase oxidation, etc. In short, as long as the strict production of zinc, or can be eliminated.

-

The advantages of galvanized pipe are as follows:

1, Galvanized pipe can be protected by hot galvanized surface, and the inner cavity of the tube or any other coating angle difficult to enter, deepen the zinc easily covered to the top, so that the entire galvanized pipe is protected.

-

Low-carbon steel pipe generally rolled into angle, channel, I-beam, steel, steel or steel. It is widely used in various building components, containers, huts, stoves and agricultural machinery. Low-carbon high-quality steel rolled into thin-sheet production car cab, hood and other deep wahsed products. It can also be rolled into strips for dmanding production of machine parts. Mild steel is generally not used after heat treatment, when the carbon content by carburizing or cyanindation of 0.15% or more, can be used for shafts, bushings, sprockets and other parts of the surface temperature requirements, wear-resistant.

-

Livable cities generally have two pipeline systems that supply water pipes and sewage sewer system, also known as the third set of piping systems in the pipeline system, is a water supply system, sewage together, after purification treatment, continue to apply as a living miscellaneous water supply system. United States, Japan, India, Russia have established a municipal wastewater reuse system.

-

The welded pipe is called the welded pipe for short, and the commonly used steel or steel strip is welded by the curled forming of the unit and the mold. The production process of welded steel pipe is simple, the production efficiency is high, the specifications are many, the equipment is less, but the general strength is lower than that of the seamless steel pipe. Since 1930s, with the rapid development of high-quality strip rolling production and progress of welding and testing technology, and constantly improve the weld quality, varieties and specifications of welded steel pipe is increasing, and in more and more fields especially in the heat pipe, who spare decorative tube, tube for low-pressure fluid etc. instead of the seamless steel tube. The production process of the straight welded pipe is simple, the production efficiency is high, the cost is low, and the development is fast. The strength of the spiral welded pipe is generally higher than that of the longitudinal welded pipe. The welded pipe with larger diameter can be produced with a narrow billet, and the welded pipes with different diameters can also be produced with the same width blank. But compared with the same length, the length of the weld increases by 30~100%, and the production speed is low.

-

According to the manufacturing process of steel pipe, seamless steel pipe can be divided into (SML), as the main oil gathering pipe and the small caliber high pressure natural gas pipeline, the number for the long oil pipeline is very few, most of the pipeline is the use of high-frequency welded pipes (ERW), spiral submerged arc welding pipe (SSAW) and LSAW (LSAW) three. The following table for several technological characteristics of the steel pipe and the quality of performance comparison: high-frequency welded pipes (ERW) according to the different welding modes are divided into induction welding and contact welding in two forms, the hot-rolled steel coil as raw material, after pre bending, continuous molding, welding, heat treatment, sizing, straightening, cutting and other processes. Compared with the spiral welded seam with short, high dimensional accuracy, uniform thickness, good surface quality, high pressure, but the drawback is the production of small diameter thin-walled tube only, weld is easy to produce gray spot and lack of fusion, groove corrosion defects.

-

ERW is the first letter of resistance welding Electric resistance welding abbreviation ERW pipe and submerged arc welding pipe welding methods are significantly different, the use of unfilled metal pressure welding, the weld is not filled with other components, by high-frequency current The skin effect and the proximity effect, so that the instant plate edge heated to the welding temperature, squeezed by the extrusion roller forging the formation of the weld.

-

Super Fishing Ground China's 12 typhoon has been delivered to Norwegian users. Super Fishing Ground has installed more than 20,000 sensors of various types and integrated into multidisciplinary technologies such as biology, engineering, electrical and computer, which can realize automatic monitoring, feeding and cleaning. It is the first and largest contract in our country to establish a contract Deep sea semi-submersible intelligent farm. It is a fishing farm and a comfortable home for modern marine life.

-

Steel pipe manufacturing process according to different, can be divided into (SML), as the main oil gathering pipe and the small caliber high pressure natural gas pipeline, the number for the long oil pipeline is very few, most of the pipeline is the use of high-frequency straight seam (ERW), spiral submerged arc (SSAW), submerged arc (LSAW) three.

-

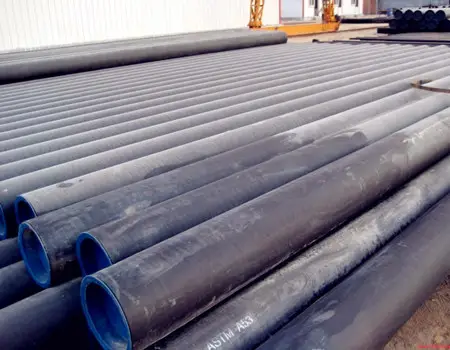

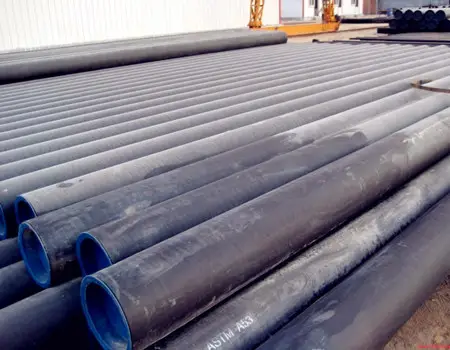

Seamless pipe are extensively applied for the nuclear device, gas, petrochemical, ship building and boiler industries. Below we will introduce the wall thickness tolerance of seamless steel pipe.

-

Ordinary steel pipes, such as tap water pipes, are usually welded by plate after bending. You can find a weld on it. The diameter of the steel is generally spiral.

The seamless steel pipe is usually formed by pressing the molten steel through the annular slit and then drawing through the drawing process so that there is no weld. It is often used in high pressure equipment in performance, especially in pressure bearing capacity, which is much higher than that of ordinary steel pipes.

-

BEIJING, Jan. 07 (Xinhua) -- The Ministry of Commerce (MOC) said on Friday that it will take the necessary steps to protect the legitimate rights of Chinese companies following anti-dumping measures taken by the European Union.

-

SAE1030 seamless steel pipe

-

SAE5130 seamless steel tubes/pipes is one of the ASTM grade, mainly applied to cold rolled Seamless precision steel tubes/steel pipes. SAE 5130 Seamless teel pipe must be compatible with production methods of the outside surface and inner surface. Henan Bebon can supply SAE 5130 Steel Pipe/Tubes/Seamless Pipes.We exported this material 800 tons monthly.We are professional steel pipe manufacturer/mill/factory /supplier/exporter/producer. Regarding the dimension of the tubes, we can supply the common sizes and or produce according to customers’ requirements.We have established steady business relations with customers from all over the world..If you need any Steel Pipe/Tubes/Seamless Pipes, please contact us by sending mail, calling, leaving message on our website. We will supply you the goods at the competitive/ lowest price of SAE5130 seamless steel tubes. We will be your best choice and your best supplier in China.

-

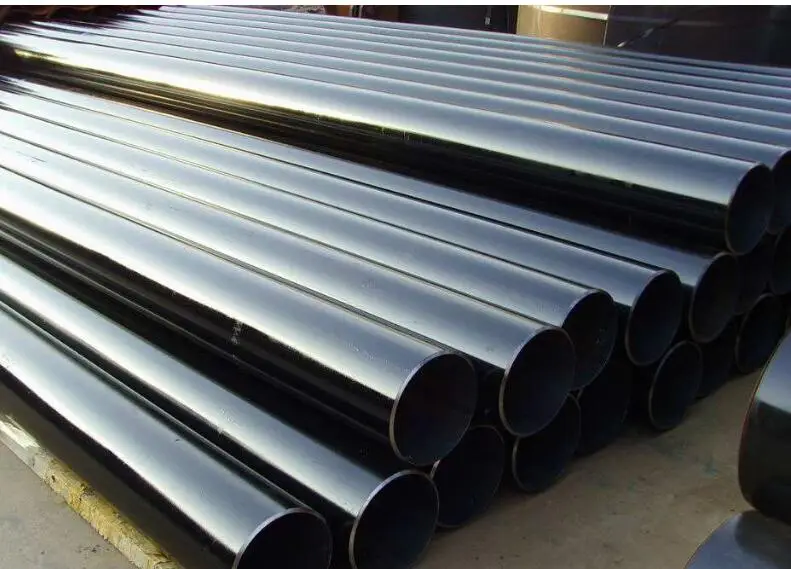

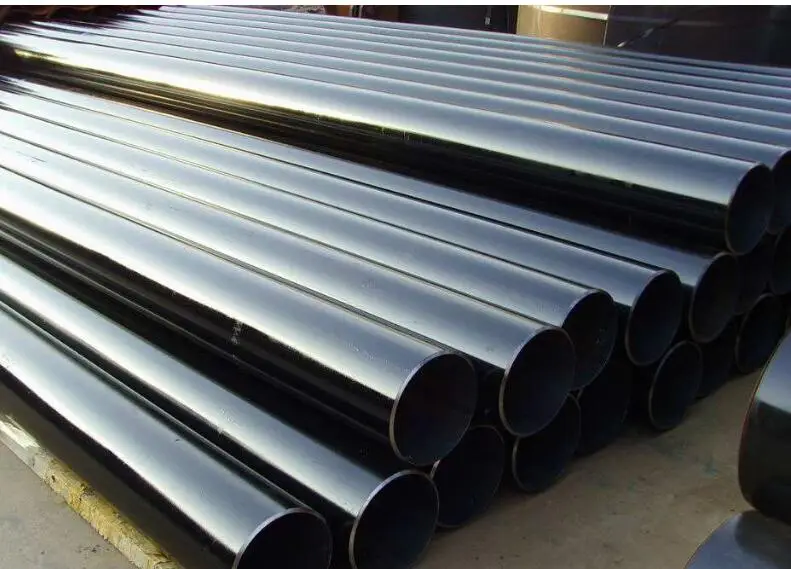

Galvanized steel pipe is the surface with hot-dip galvanized or electro-galvanized layer. Galvanized steel can increase corrosion resistance and prolong life. Galvanized steel pipe is widely used, except for water, gas, oil, generally low-pressure fluid line pipe, also used oil heater oil industry in particular, marine oil wells pipes, pipelines, chemical coking equipment, condensing coolers, washing coal distillate oil exchange used tubes, as well as the bridge piles, mine tunnel support frame with a pipe.

-

SSAW steel pipe is the steel pipe with spiral seam that using strip coil as raw material, extrusion forming under normal temperature, and welding by automatic Double wire double-sided submerged arc welding process. Classification of SSAW steel pipe includes:

-

Low carbon steel pipe is plastic material. The stress-strain curve in the tensile process is divided into four stages: Elastic stage, yield stage, strengthening stage, local deformation stage. In the local deformation stage there are obvious yield and necking phenomenon. At the beginning of the elastic phase, fully comply with Hooke's law along the straight line, after the proportion of speed limit to accelerate, but no obvious yield stage.

-

Steel Pipeline pickling methods can be divided into groove type pickling and circulating acid, the cycle can be divided into online circulation pickling and pickling line the outer loop.

-

1. Chemical composition analysis: chemical analysis, instrumental analysis (infrared C-S instrument, direct reading spectrometer, zcP, etc.).

① infrared C-S instrument: analysis of ferroalloy, steelmaking raw materials, steel in the C, S elements.

Direct Reading Spectrometer: C, Si, Mn, P, S, Cr, Mo, Ni, Cn, Al, W, V, Ti, B, Nb, As, Sn, Sb, Pb,