-

Currently, Korean steel pipe manufacturers are struggling to cope with the threat of a decline in exports. South Korean steel pipe industry said that before the Korean steel pipe exports continued to rise, but began to deteriorate in the middle of this year, and the situation in the second half may be even worse.

-

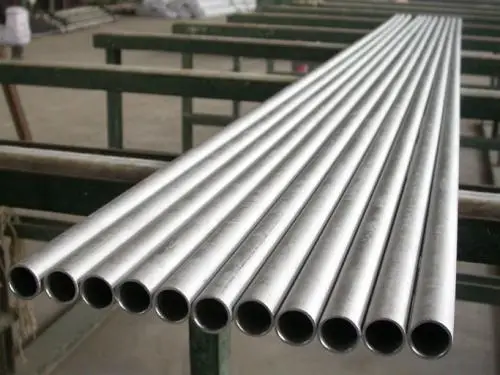

Welded Stainless Steel Tubes

Scheduled pipes

Tubes for heat exchangers and air coolers

-

The quality of the perforated capillary has a very important effect on the quality of the hot rolled seamless steel tube because of the surface defects or eccentricity (uneven thickness) of the worn capillary. The way pressure pipe punching punching, pushing rotary perforation and perforation. Thick wall seamless steel is mainly used in oil geological drilling pipe, and petrochemical used in cracking pipe, boiler tube, pipe and automobile bearing, tractor, aviation and other precision pipe structures, its manufacturing process: hot rolled seamless steel pipe circle, heating, three porous roller, rolling or extrusion, separation, slurry (or reduced) cooling, straightening,?? water pressure Test (or test) marks - storage.

-

Seamless steel pipe is one of the important products of OCTG products. It is widely used in manufacturing structural parts and mechanical parts, such as petroleum drill pipe, automobile transmission shaft, bicycle frame and steel scaffolding. Compared with other steel tubes, seamless steel tubes have stronger bending and torsion capacity under the same cross-sectional area. It is widely used in the national economy and has the right to "industrial vessels". Therefore, the quality requirements of seamless steel tubes are very demanding.

-

Many people think that stainless steel is not rust steel, of course. The stainless steel pipe elbow anti rust mechanism is to form compact alloy oxide film, isolate oxygen contact and prevent oxidation. So stainless steel is not "stainless steel". Stainless steel has the ability to resist atmospheric oxidation, that is, stainless steel, and has corrosion resistance in acid, alkali and salt media, that is, corrosion resistance. After the Prime steel pipe, the main factors affecting the corrosion of stainless steel are understood.

-

1, power plant pipe pulverizing system, including powder pipeline, thick powder separation pipe, coal dropper, wind pipe combustion system, two wind pipe, three pipe and burner pipe, except ash system discharge pipe, powder pipe, dry ash conveying pipe;

2, raw material pipeline of iron and steel plant, collecting pipe, dust collection pipe, ash pipe, ash pipe, mixing pipe, grinding outlet pipe, coal pipe, coal pipe, separation pipe, burner radius pipe, etc.

3, the cement plant chooses machine outlet pipe, choose machine inlet pipe, pipe dust removal pipe, vertical mill outlet pipe, circulating air duct, high temperature blower, blanking pipe and so on.

4, petroleum, chemical, mining, coal, coal washing plants, smelting, paper making, aluminum, building materials, powder engineering, food machinery and other processing and conveying materials pipes

-

Low carbon steel tubes are made of ceramics with high wear resistance and resistance to fluid erosion. In the wind pipe, the wear rate of the pipe is the fastest, and the wear resistance of the ceramic lined steel pipe elbow is more than five times higher than that of the steel elbow. In practical application, the ceramic lined steel pipe has been observed and measured 1-2 years after opening the hole. The composite layer has no obvious wear or loss, the size of the unit and the length of the pipe are the same. The weight of the ceramic lined steel pipe is about 1/2 with the weight of the wear-resistant steel pipe or the double metal composite pipe. The construction cost is reduced by 30-40% per meter, and only the cast stone weight steel pipe is used. And rare wear resistant 2/5 around 20% per meter below the cost of the project. The cost of ceramic lined steel pipes is only a small part of stainless steel tubes and nickel titanium pipes when they are corroded or used in high temperature.

-

Ceramic lined steel composite pipes have excellent wear resistance. The service life of materials used in hard abrasives is 20 times longer than that of ordinary steel pipes.

The combination of high rigidity and high elastic steel makes the pipes unrivalled and can be used as wear-resistant, heat-resistant and corrosion resistant materials in the fields of power generation, metallurgy, mining and chemical industry.

-

The steel should meet the requirements of chemical composition, tensile properties and hardness. Water pressure test should be carried out in every pipe. In addition, each pipe should be inspected according to the required practice by NDT.

Mechanical test requirements for different pipelines, such as lateral or longitudinal tensile tests, flattening tests and hardness or bending tests, are presented.

The ends of each box will indicate order number, heat number, size, weight and binding or as required.

-

Ceramic Lined Lateral pipe Wye from a single spool piece to complete piping systems.

-

Expansion joints are designed to safely absorb the movement in pipework systems due to heat-induced expansion and contraction of pipework.

-

Ceramic Lined Reducer Pipe with flange

-

Ceramic Lined Elbows and Bends could be also applied in the parts of concrete pump owing to their advantages especially the low weight which helps to avoid the jam during the transport of concrete.

-

Abrasion resistant Straight pipe

-

A694 F65 Flanges for Nigeria

-

The advantages of this ERW steel tube processing technology are that there is a heat treatment process after welding to eliminate the residual stress in the weld and heat affected areas, to refine the grain, and to make the heat affected zone of the weld small, and the heating speed is fast, thus greatly improving the welding speed and welding quality, and can be used as a blank without pickling, shot peening and trimming. At the same time, it can weld alloy steel, high alloy steel and non-ferrous metal pipe, greatly reducing unit power consumption. A set of welding equipment can be used to produce each.

-

With the support of professional team and perfect production department, we are able to provide customers with impeccable alloy steel seamless boiler tubes.

-

pearlitesteel.com

-

Nowadays, ERW welding stainless steel pipe products play an important role in every industry field. Stainless steel pipes and tubes have excellent corrosion resistance and smooth finish characteristics. The corrosion resistance of welded steel is the same as that of base metal, and its strength is higher than that of base metal. For these reasons, they are used in demanding industries, such as

-

he structure load to rock formations or to stronger soil conditions deep beneath the ground. DMH USI has the ability to cut and splice various diameters and wall thicknesses of carbon steel pipe piles to accommodate the specific load requirements of these structures. We also have the ability to fabricate piling lengths up to + or - 93 feet and to attach plates, shoes or conical points as required. We offer mechanical & t

-

Since 1992, Southland Pipe & Supply has provided carbon steel pipe fabrication for customers and distributors across the Southeast, and across the country. As a nationwide supplier of made to length prime pipe, structural grade pipe, and fabricated steel pipe assemblies, we mechanically bevel and torch cut, weld, fabricate, coat, and truck our custom manufactured products throughout the United States. We have 25 welding and pipe fabricating employees who, on average, have 5-10 years experience with us.