-

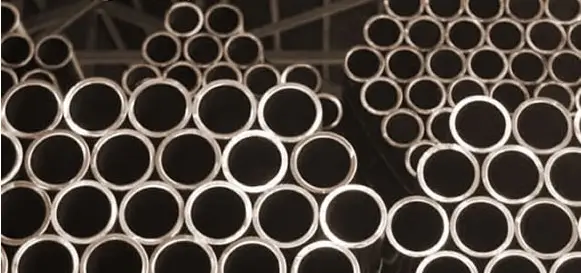

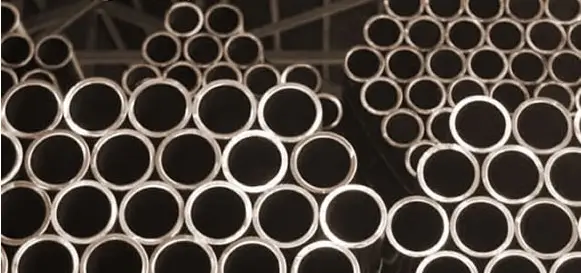

Tubo de acero sin costura están perforados de acero redondo entero, y los tubos de acero sin soldaduras en la superficie se denominan tubos de acero sin costura.

-

Prueba de conocimientos de galvanización

-

Beneficios de usar tubería de acero inoxidable de pared delgada

-

-

-

Conocimiento del ámbito de aplicación de los tubos de acero sin costura en diferentes campos

-

La tubería de acero inoxidable es un acero redondo largo y hueco, que se usa ampliamente en petróleo, química, medicina, alimentos, industria ligera, maquinaria e instrumentación y otras tuberías industriales y piezas estructurales mecánicas. La tubería de acero inoxidable es un tipo de acero de sección transversal económica . Es un producto importante en la industria del acero. Por lo general, representa alrededor del 8% -16% del acero total. Tiene una amplia gama de aplicaciones en la economía nacional y es en sí mismo un ahorro La sección económica del acero metálico es un parte importante del acero de alta eficiencia, especialmente en las industrias de perforación, fundición y transporte de petróleo.

-

Especificación de tamaño de tubería de acero soldada eléctricamente de gran diámetro

-

Proceso de producción de tubería de acero con costura recta (LSAW) de soldadura por arco sumergido d

-

1. Carbon seamless steel pipe quality inspection and acceptance by the supplier technical quality supervision department

2. The supplier must ensure that the delivery of steel pipe in accordance with the provisions of the corresponding product standards. The purchaser shall have the right to inspect and inspect the product according to the relevant product standards

3. Carbon seamless steel pipe should be submitted in bulk acceptance, the group approved the rules should be consistent with the provisions of the corresponding product standards.

4. Carbon seamless steel pipe inspection items, sampling number, sampling sites and test methods, according to the provisions of the corresponding product standards. The consent of the demand side, hot-rolled seamless steel tube can be sampled by rolling the root array.

5. Carbon seamless steel pipe test results, a non-compliance with product standards, should be unqualified singled out, and from the same batch of steel pipe, either take double the number of samples for failure of the project re-test .

-

According to Indonesia, "Jakarta post" reported on February 8th, the Indonesian iron and Steel Association released data show that in 2017 Indonesia imported 6 million 430 thousand tons of steel, accounting for 48% of the total annual steel consumption in 2015 and 2016, respectively; Indonesia imported steel 6 million 850 thousand tons and 6 million 490 thousand tons, is the world's five largest importer of iron and steel.

-

The difference between stainless steel thick-walled seamless tubes and carbon seamless steel tubes mainly refers to the difference in design rules between stainless steel and carbon steel, that is, the design rules of these two types of steel are not common. The differences are summarized as follows: Stainless steel design rules cannot be applied to carbon steel because there are three fundamental differences between stainless steel and carbon steel:

-

High-frequency welding machines can be used for the welding of metal pipes, such as: copper pipes, brass, brass and steel pipes, steel pipes and steel pipes, steel pipes, cast iron pipes, copper pipes, iron pipes, iron pipes, iron pipes, copper pipes, aluminum pipes ,Steel pipe, aluminum alloy, aluminum and aluminum alloy pipe butt welding, welding, welding, etc., welding metal pipe (silver welded ring recommended welding) advantages:`2

-

Large diameter straight seam steel pipe is widely used in aviation, aerospace, energy, electronics, automotive, light industry and other industrial sectors, and is an important welding process.

-

Stainless steel pipe elbow has excellent corrosion resistance, stainless steel surface thin and strong oxide film so that all stainless steel in all water quality has excellent corrosion resistance, even buried also has excellent corrosion resistance. So it is suitable for a variety of water quality, in addition to disinfection and sterilization, do not need to control the water quality, at the same time, there is no corrosion and excessive exudate, to maintain clean water quality, to prevent secondary pollution, can withstand up to 30 meters per second The impact of high water flow.

-

Galvanized seamless steel pipe galvanized layer and small, only 10-50g / m2, the corrosion resistance of its hot-dip galvanized pipe is poor, hot-dip galvanized pipe. Ordinary galvanized pipe manufacturers use cold galvanized pipe as quasi-cold water and gas pipelines. Galvanized steel cold galvanized layer galvanized, layered zinc layer and the steel matrix. A thin layer of zinc, zinc layer simply attached to the steel substrate. Therefore, its corrosion resistance is poor. In new houses, galvanized steel is prohibited as a cold water supply.

-

The advantages of straight seam welded pipe compared with seamless steel pipe are as follows:

-

X-ray Inspection Operate of Wall Thickness SSAW Steel Pipe

-

ASMT A333 1 seamless and welded pipes should be treated to control their microstructure. Tensile test, impact test, hydrostatic test and non-destructive electrical test shall be carried out according to the prescribed requirements. ASTM A333 1 is part of the standard covering wall seamless and welded carbon and alloy steel tubes, designed for low temperature use. ASTM A333 1 grade alloy pipe should be manufactured by seamless or welding process without filler metal in welding operation. Seamless and welded steel tubes for low temperature service:

-

1mechanical polishing

The 1. advantage is that the parts are smooth and the brightness is high after processing. The disadvantage is that the labor intensity is too big, cause serious pollution, can not process complex parts, the luster can not be consistent, the heat preservation time is not long, the mechanical polishing is suitable for the processing simple parts, and the small and medium parts.

-

US final anti-dumping industry damage to China's stainless steel flange