-

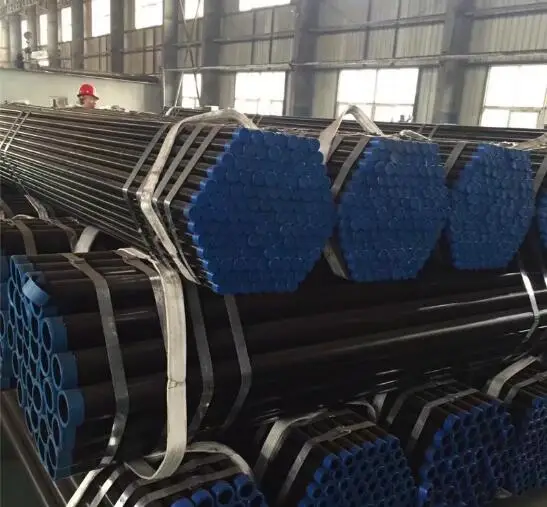

When steel pipe is completed and operational, it is the result of cooperation between a number of parties in the supply chain. These parties perform steps which are sequential and overlapping involved in the design, manufacturing, blasting, coating, handling, storage, transport and construction of steel pipe.

-

150# Plate Steel Slip-On Flange

Sizes ranging from 1-inch to 18-inch

304 Stainless Steel Plate Slip-On Flange, 150# Drilling

Sizes ranging from 1-inch to 12-inches

316 Stainless Steel Plate Slip-On Flange, 150# Drilling

Sizes ranging from 1-inch to 12-inche

-

As the name suggests, seamless pipes are pipes without joints or welded joints, rather than welds or welded pipes. In joints or welded pipes, joints or welded joints are the weaker parts of pipelines, which limit the strength of pipes to achieve the strength of welded joints. Seamless pipe has no such joint, so it has uniform structure and strength on the whole pipe. Therefore, seamless tube can withstand higher pressure, higher temperature, higher mechanical stress and corrosive atmosphere, and is widely used in oil and natural gas, oil refinery, petrochemical, chemical, chemical fertilizer, electric power, automobile, bearing, mechanical and structural applications.

-

Hot-rolled seamless steel pipe production base deformation process can be summarized as three stages: perforation, extension and finishing.

-

There are cracks in the welding process or design of the stainless steel pipe joint at the other joint. In effective corrosion sites, the crack must be wide enough to allow corrosive electrolyte to enter the stagnant zone. The width of the corrosion crack is several meters wide, but it is not absolute. The critical crack size leads to corrosion.

-

Check and check the complete data of the stainless steel pipe.

We know that stainless steel seamless pipes have high quality requirements for seamless pipes under high temperature and high pressure.

-

1, online nondestructive testing

The detection arm of the testing station rotates and is placed on the longitudinal welded pipe production line. Observe the position of the weld through a camera. The position of the probe is adjusted by the lever so that the weld overlaps with the laser and saves the parameters. Input the coil number through DATASERVR and DACQ computer. The waveform of the observation defect detection interface is displayed. When the waveform exceeds the alarm line, the thickness measurement information is compared to determine whether it is a defective or interfering wave signal, and the naked eye is checked to see if the waveform is beyond the alarm line. If the alarm line exceeds the alarm line, the alarm will be issued. Close and adjust the welding parameters in time.

-

Requirements for the use of galvanized insulated steel pipes for buildings:

1, galvanized insulated steel pipes are used for long-distance transportation of natural gas and high pressure pipes.

-

Seamless casing is an important equipment for oil drilling. It is also the other equipment of drilling and drilling, core pipe, casing, drilling, small diameter drilling casing and so on. The support of the borehole ensures that the drilling process stops and the well is fully operated after completion. Therefore, processing oil drilling to eliminate the problem of wear-resistant drill rod, it is difficult to dismantle the drill rod joint performance when the external wear belt is difficult to disassemble, the operation is complicated and safe, the degree of automation is high, the joint efficiency is high, and the cutting is clean. For a wide range of pipe diameter, the music tone is small, and the use of oil sleeve will not clean the environment, equipment debugging is also very convenient.

-

1.1 this specification covers thermoforming welding and seamless carbon steel square, circular, rectangular or special shaped structure tubes for bridge and building welding, riveting or bolt connection and general structural use.

1.2 square and rectangular pipes are from 1 to 10 inches (25.4 to 254 millimeters), and the plane wall thickness is 0.095 to 1000 inches (2.41 to 25.40 mm), depending on the size. The circular pipe is provided, including the nominal (average) wall thickness of 0.109 to 1 inches (2.77 to 25.40 milli meters), and the size depends on the size. As long as this pipe meets all other requirements of this specification, it can provide other sizes of pipes.

1.3 pipes can be equipped with hot dip galvanized coating.

1.4 the value expressed in inch pound units should be used as a standard.

Note in this standard, the dimensionless indicator NPS (nominal diameter) has been replaced by the traditional term "nominal diameter", "size" and "nominal size".

-

ASTM A572-50 is a high-strength, low-alloy (HSLA) columbium-vanadium steel. It has a higher yield and tensile strength, as compared to ASTM A36. The higher tensile strength of A572-50 allows reduction of section thickness and weight when manufacturing parts, therefore lowering the overall weight of the part. It is easy to weld, form, and machine when using appropriate techniques.

ASTM A572 is also available in grades 42, 55, 60 and 65.

-

Masteel UK Ltd are a global steel supply and stockholding company, supplying the engineering, power generation, petrochemical, oil & gas and nuclear industries.

Partne

-

Product Discription:

Usage: Used for low pressure liquid transportation, such as water, gas, and oil. Oil drilling and machinery manufacturing, etc.

ERW : Electric Resistance Welded pipe

HFI: High Frequency Induction weld pipe

EFW: Electric Fusion Welded Pipe

Standard: API 5L, API 5CT, ASTM 53, EN10217, DIN 2458. IS 3589, JIS G3452, BS1387

Certificate: API 5L PSL1/ PSL2, API 5CT

Out Diameter: 21.3mm -- 660.4mm(1/2"--26")

Wall Thickness: 1.5 - 22.2mm

Length: 0.3 – 18 M

Steel Grade: API 5L : GR B, X42, X46, X56, X60, X65, X70

API 5CT: K55, J55, N80 P110

ASTM A53: GR A, GR B

EN: S275, S275JR, S355JRH, S355J2H

GB: Q195, Q215, Q235, Q345, L175, L210, L245, L320, L360- L555

Surface: Fusion bond Epoxy coating, Coal Tar Epoxy, 3PE, Vanish Coating, Bitumen Coating, Black Oil coating as per customer’s requirement

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test.

Mill Test Certificate: EN 10204/3.1B

-

Seamless tubes are widely used in nuclear devices, natural gas, petrochemical, shipbuilding, boilers and other industries. Seamless steel tubes account for 65% of the market share in China's boiler industry.

The main customers of the international market: Alstom, Becket, Siemens Austria, Petrobras, Doosan Heavy Industries, Hyundai, Ethel, Bell and so on.

-

We use a strict quality monitoring system to test the raw materials in the production process and test each product to ensure that each pipe meets the standard requirements and fully meets the requirements in the factory.

-

Internationally, the requirements for casing threads between one pair of inner and outer cones meet the requirement of end face allowance only, and the axial displacement can be used to complete the interference of the connection surface. And it can be used to improve the processing quality of the connection area, increase the axial force to increase the pressure of touch area and touch area, and then get a more compact ring pressure touch area. The larger the touch area, the less likely the leakage path is, and the more reliable the sealing function is. Casing thread is a special conical seal with thread grooves and taper pipe threads.

-

In order to maintain a stable heat treatment product during the induction heat rapid heat treatment process, the following measures should be taken on the production line:

-

The pressure of the API 5CT oil casing in the oil well: to ensure that the casing enters the well continuously, without cracks or deformation, the casing is required to have a certain strength to resist the external force it receives. Therefore, it is necessary to analyze the stress on the casing of the inner well.

-

Casing is the high end product of steel pipe production. There are many kinds of bushings. There are 15 kinds of casing diameters. The diameter range of 114.3-508mm steel; divided into J55, K55, N80, L-80, P-110, C-90, C-95, T-95 and other 11 kinds of casing; end buckle type and many types of requirements, processing button type STC, LC, BC, VAM, buckle type. The process of casing production and installation involves many tests. The main points are as follows:

-

The seamless tube used for heat exchanger is one of the components of the heat exchanger, and is placed in the cylinder for exchanging heat between the two media. It has high thermal conductivity and good isothermal properties. It is a device that can quickly transfer heat from one point to another, with little heat loss, so it is called a heat transfer superconductor, which has a thermal conductivity of several thousand times copper.

-

Foreign overseas platform material number

S355G2 + N, S355G3 + N, S355G5 + M, S355G6 + M, S355G7 + M, S355G7 + N.