-

1) roller: it is the main transmission deformation tool. Usually, the roller consists of an inlet cone, a rolling belt (also called a compression belt) and an outlet cone. Its function:

One. Injection cone: enter the tube blank and realize the perforation of the tube.

The outlet cone of the bay is designed to reduce the hair wall, smooth the surface of the capillary, uniform the thickness of the capillary wall and complete the capillary backflow.

C. Rolling belt: transition from inlet cone to outlet cone.

-

In the hydraulic test of the ERW pipe, it is often found that the rupture opening is broken off from the weld line of the ERW pipe, which indicates that the strength of the welded part is lower than that of the base metal. Through the experimental analysis, it is found that the thickness of the sample in the weld is reduced if the internal scratching groove is formed on the inner surface of the steel pipe during the removal of the burr in the weld. In tensile tests, samples are easily broken from this point.

-

Requirements for API 5L X52 seamless tube in standard

1. there are no cracks, wrinkles, wrinkles, spalling, crusts and scales on the inside and outside surfaces of the steel pipes. These defects should be completely eliminated. The grinding of surface defects should be smooth and smooth. The depth of clearance should not exceed the negative deviation of nominal wall thickness. The actual thickness of the defect removal zone should not be less than the minimum allowable wall thickness of the steel tube. The welding method should not be used.

-

There may be hundreds of different ways of packing pipes, most of which have advantages, but there are two principles that are critical to any method of preventing the safety of rust and maritime transport.

-

According to the need to cut the length of the pipeline. The cutting tool has a grinding wheel cutting machine (also known as toothless saw), hand saws, cutters and other hand tools.

The grinding wheel cutting machine: suitable for cutting metal pipe or metal material, especially batch cutting is the most economical. You need to determine the needs of pipe cutting length, and then draw the cutting line. Cutting fixture before the pipe cutting machine should be firmly fixed. The machine starts slowly, press the wheel, don't slam or slam on the wheel pressure is too large, so as not to burst accident.

-

It is necessary to connect pipes together or change the direction of existing pipelines. Depending on the fluid or gas transported, pipes and piping joints are made of various materials. Most pipe fittings tend to thread or slide through the pipes they connect. Whether you are using a PVC pipe, chemical solvents are needed to form a seal between pipes and pipes.

Measure the required length of the pipe to be installed, and remember the extra length required to insert the pipe into the fittings. Mark this length on the pipe.

-

The cracks of pipeline weld often follow different mechanisms, which can be divided into two types: hot cracking and cold cracking. It is produced by the thermal cracking of molten metal into solid crystallization, which is mainly produced in weld metal. The main reason for the low melting point material is that it exists in the weld, which weakens the contact between the grains when the high welding stress is accepted, and it is easy to lead to the breakdown between the grains. Hot spots are easy to occur when electrodes and electrodes contain impurities such as S and Cu for a long time.

-

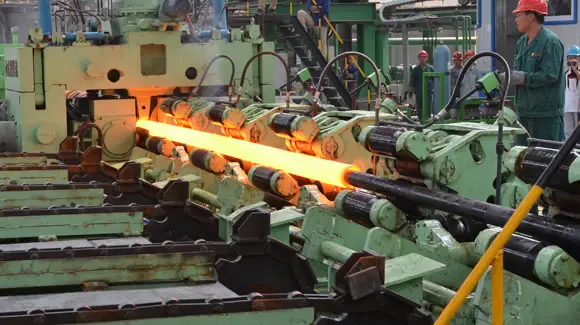

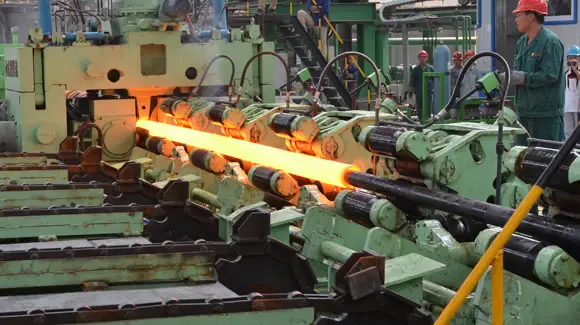

The cross roll piercing and pilger rolling process in the size range from approx. 250 to 660 mm outside diameter.

Generally the billet is plastically deformed at a certain temperature environment, through a dedicated mold, the metal to produce a continuous smooth flow of the process to achieve the deformed geometry requirements.

Perforation is to wear a circular cross-section billet deformation tube made of wool.

-

There may be hundreds of different ways of packing pipes, most of which have advantages.

But there are two principles that are essential for any rust prevention and maritime transport safety.

-

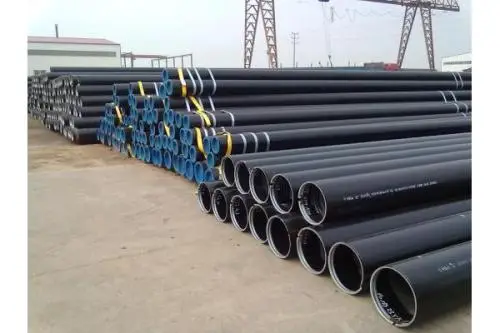

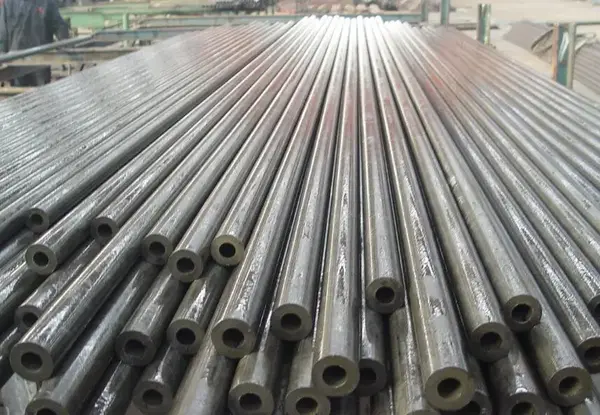

Seamless pipes are widely used in nuclear devices, natural gas, petrochemical, shipbuilding and boiler industries. Seamless pipe occupies 65% of the market share of China's boiler industry.

-

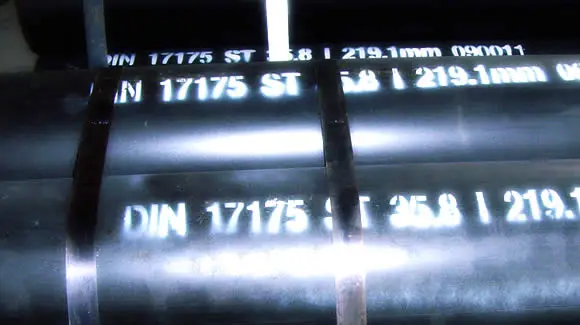

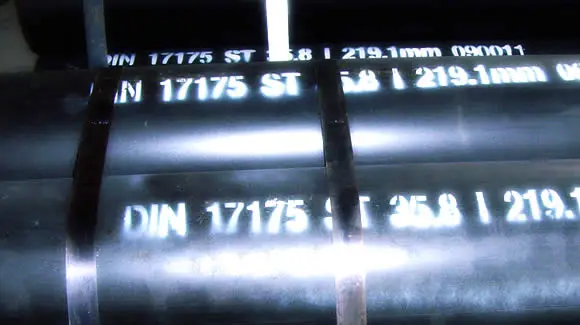

DIN 17175 steel pipe is used for boiler installation, high pressure pipeline and oil tank structure and special machinery for high temperature and high pressure equipment.

-

DIN 17175-79 alloy steel pipe is just a big class,and it has many classifivations.

We mainly produce DIN 17175 ST35.8,DIN 17175 ST45.8, and 10CrMo910 steel pipes.

-

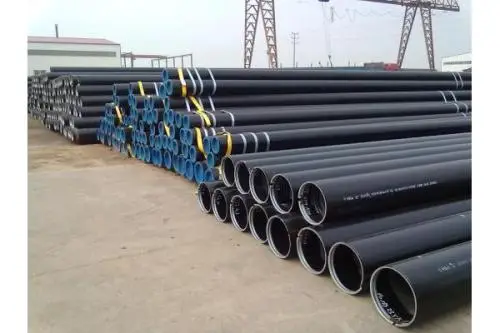

Inner packing:Caps on two ends of every pipe

Packing: Bare/bundles/crates/crate protection at the both sides of tubes or as per customers’ requirements .

Surface treatment:Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting.

Marking: as per customer’s requirement

-

The seamless tube used for heat exchanger is one of the components of the heat exchanger, and is placed in the cylinder for exchanging heat between the two media. It has high thermal conductivity and good isothermal properties. It is a device that can quickly transfer heat from one point to another, with little heat loss, so it is called a heat transfer superconductor, which has a thermal conductivity of several thousand times copper.

-

We are the leading company to successfully handle alloy steel seamless pipes and alloy seamless pipes. In addition to carbon, they also contain large amounts of nickel, manganese, chromium, silicon, tungsten, vanadium and molybdenum. In addition, these also add limited elements, such as sulfur, silicon, manganese and phosphorus, which help to increase.

The hardness of the pipe

The strength of the pipe

Chemical resistance of pipes

-

introduce

The alloy steel is specified by the AISI four digit number. They are more responsive to mechanical and heat treatment than carbon steel. They contain different types of steel whose composition exceeds the limits of B, C, Mn, Mo, Ni, Si, Cr and Va in carbon steel.

-

Standard Specification for ASTM A795 for black and hot dip galvanized (Galvanized) and seamless steel tubes for fire protection

-

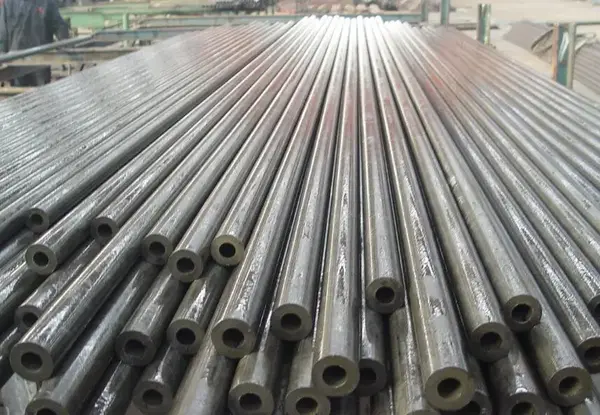

The circular steel tube is a hollow concentric circular section steel tube with both ends open, and its length is relatively larger than its circumference. It can be used in pipes, thermal equipment, machinery industry, petroleum geology drilling, containers, chemical industry and special applications.

-

1, water supply and drainage

Building water supply system can be divided into living water supply system, production water supply system and fire water supply system according to its application. These three kinds of water supply systems are not necessarily separately set up, usually two or three kinds of water supply systems. The building drainage system collects water used by buildings in daily life and industrial production, and drains them out in time. According to the nature of sewage discharged from the system, the internal drainage of buildings can be divided into domestic sewage, domestic sewage, industrial waste water and roofing. Rainwater, sewage (wastewater), industrial waste water and rainwater are set to discharge pipes, known as diversion systems; two or more types of combinations in a pipeline are called combined flow systems; the requirements for different forms according to the water quality conditions and locations are determined after technical and economic comparisons.

-

Industrial pipeline is an industrial pipeline. Industrial pipelines can be further subdivided into process pipelines and power pipelines. In general, the flow pipeline refers to the pipeline that directly conveyed the main material (medium) of the product, also called the material pipe, and the power pipeline refers to the pipeline that conveyed the power medium for the production equipment such as steam pipe, air pressure pipe, nitrogen pipe, cyclopentane and other production equipment. Paraffin pipes, oxygen pipes, etc. Power lines affect the normal operation of production.

-

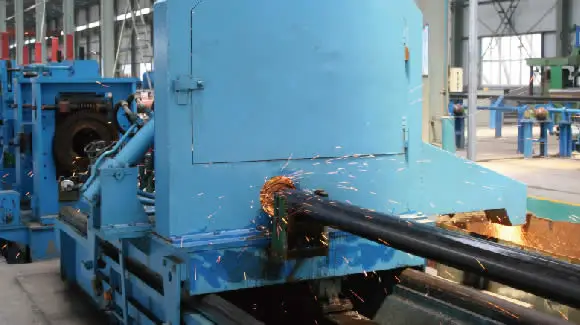

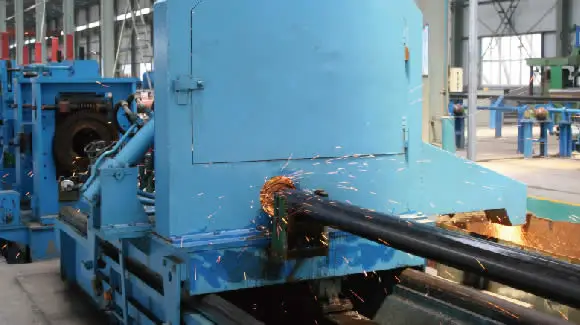

Resistance welding is to clamp the workpiece between two electrodes and apply a current. The current is heated to a molten or plastic state through a resistance heating effect flowing through the contact surface of the workpiece and the current in the adjacent region to form a metal. A combination of methods. The welded pipe made of resistance welding is called the resistance welded pipe (ERW pipe).