-

During the construction of natural gas and oil pipeline stations, the installation of valves, meters and flanges should be tapped in the main channel. It is difficult to identify the straight seam position of the base pipe by high-frequency resistance welding. The installation of some lugs is very close to the welding seam. Therefore, it is very necessary to deeply study and analyze the influence of the boss on the basic pipeline. In this paper, the residual stress distribution of high frequency longitudinal resistance welded pipe is analyzed, and the influence of welding position of different boss on residual stress is analyzed. The stress increases sharply and the longitudinal welding residual stress is affected when the boss installed on the ERW pipe is much larger than the parent pipe.

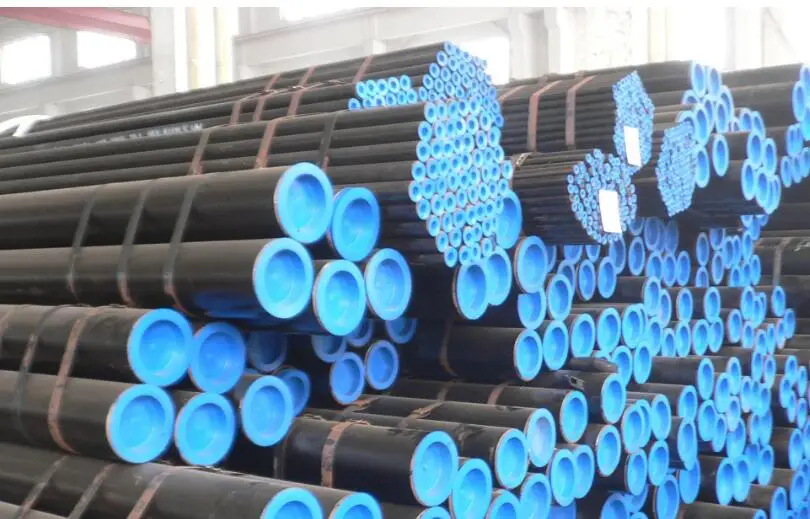

ERW pipeline

-

The ERW welding machine technology is used to realize the high frequency welding of the electromechanical system. The high-frequency welding equipment is composed of a high-frequency welding machine and a forming machine. A high frequency welding machine is usually made up of two parts of high frequency generator and feed device. The effect is to produce high frequency current and control it. By extrusion roll frame, the function of the molding machine is high frequency current. The extrusion and melting part eliminates the oxide and impurities on the surface of the steel and makes the steel plate completely integrated into one.

ERW pipeline

-

LSAW pipe fracture, hydraulic (pneumatic) parts in mechanical performance design, brittle fracture is also related to the temperature of parts.

-

The principle of seamless welding is gas shielded arc welding, known as gas shielded welding or gas welding, which uses arc as a heat source and gas as a protective medium. During the welding process, the protective gas is formed around the arc to form a protective gas layer, to isolate the arc and water pit, to prevent the influence of the harmful gas and to ensure the stable combustion of the arc. Gas shielded welding is classified according to electrode state, operation mode, protection gas type, electrical performance, polarity and application scope.

Seamless welding

Seamless welding is carried out according to specific conditions. Gas shielded welding can be used with different gases, and the commonly used protective gases are carbon dioxide, argon, helium, hydrogen and gas. The advantages of gas arc arc welding are: good wire arc, easy to centering, easy to weld in all position, automatic welding, small welding arc, small welding pool, fast welding speed, narrow heat affected zone, small deformation of welding position, strong crack resistance and good welding quality. The disadvantage is that it is not suitable for welding with windy grounds, and the arc radiation is stronger.

-

Seamless steel pipe weight calculation table, the actual component of seamless pipe is calculated according to the nominal size of steel and density (formerly known as the proportion) of the calculated component called the actual component. This length and size of steel, cross-sectional area and size tolerances are indirectly related.

-

The welding process of welding pipeline unit is complicated and changeable by using uncoiling, pinch, straightening, shearing, orientation, butt welding, looper, and medium.

Welded pipe

The concrete butt welding process is:

1, when the coil is positioned well, the conical head of the coiler can be inserted into the coil at the same time, the lead is sent to the roller, and the roller is rolled down, and the coil car and the magnetic roller can be returned in situ.

-

The quality of tube billet is the main factor to judge the quality of seamless pipe. In order to ensure the reasonable progress of the perforating process and obtain high quality seamless steel tubes, it is necessary to make strict requirements for the geometrical size of the tube, the microstructure and the low magnification of the surface.

-

The uneven deformation of seamless tube during cold drawing leads to additional stress. After cold drawing, this extra stress remains in the residual stress of the tube. The degree of non-uniform deformation of seamless steel tube determines the size and distribution of residual stresses.

The deformation of the cold drawn steel is determined by the deformation characteristics. Because the tube wall processing does not involve the axis in drawing process, the thickness of the tube wall changes little after the deformation, so the deformation condition and the deformation condition of the inner and outer layers cause the seamless tube, which leads to the uneven deformation.

-

The seamless tube usually loses its bearing capacity at 450-650 degree C and experiences great deformation, resulting in bending of steel columns and steel beams. Therefore, they can not continue to use because of over deformation. Generally speaking, the fire resistance of unprotected seamless pipe is about 15 minutes. The length of time is also related to the heat absorption rate of the component. The following are several different fire prevention measures for seamless steel tubes.

-

LSAW welding machine is an automatic welding equipment, which can be automated through welding workpiece automation and mechanized linear welding. Straight seam welding machine, also known as automatic seam welding machine, longitudinal seam automatic welding machine, is an automatic welding machine. It can replace a lot of manpower, greatly improve the production efficiency and welding quality, reduce labor costs, and improve the working environment of welding workers. Such as the angle seam welding of the large transformer shell, the direct seam welding large cylinder, the direct seam welding of the solar water heater cylinder, the straight seam welding steel production line, the H type steel welding, etc., the straight seam welder is widely used.

-

The main equipment for the pipe production is as follows:

Steel milling machine: machined metal plates are machined on both sides, forming the required shape at a time. And the parallelism of the two plates reaches the prescribed tolerance range, so as to prepare for manufacturing high precision steel pipes.

-

Advantages of LSAW pipes

It can destroy the casting structure of steel ingots, refine the grain of steel, eliminate the defects of structure, make the steel structure compact and improve the mechanical properties. This improvement is mainly reflected in the rolling direction, so that the steel pipe is no longer isotropic to some extent; the dumping bubble, the crack and the loose stratum can also be welded at high temperature and high pressure.

LSAW pipeline

Sawing defect

1, the residual stress caused by unequal cooling. The residual stress is the internal self balancing stress in the absence of external force. All cross-sections of hot rolled steel have such residual stresses. The greater the size of the general section, the greater the residual stress. Although the residual stress is self balanced, the steel structure may have adverse effects on the external force, such as deformation, stability, fatigue and so on.

2, after welding, the non-metallic inclusions in the steel pipe are pressed into thin slices and stratified to reduce the thickness of the straight pipe, and the interlayer tear may occur when the weld is contracted. The local strain induced by welding shrinkage usually reaches several times the yield point strain, far greater than the strain induced by load.

-

ERW carbon steel tube has this processing technology, which has the advantages of post welding heat treatment, eliminating residual stress in weld and heat affected zone, refining grain, small heat affected zone and fast heating speed. It can greatly improve welding speed and weld quality. It can be used without pickling, shot peening and trimming steel as blank, and welding alloy at the same time. Steel, high alloy steel and non-ferrous metal pipe greatly reduce the power consumption of the unit, and equipped with a set of welding equipment can produce ERW carbon steel pipe.

-

P110 casing plays an important role in oil well operation. They can protect shallow and shallow oil wells, and also support oil and gas transportation and drilling. Support the weight of wellhead and other layers to prevent collapse. In order to ensure the smooth completion of drilling and the completion of well operation, ensure that the pipeline can be well pumped and the air pump is sent to the ground.

-

(3) For long oil and casing string, it is recommended to use sliding type elevator. Chuck and slip shall be clean, undamaged, and properly fitted. For heavy oil, casing string, extra long slips should be used and the chuck must be level.

(4) If the hoisting hook is used, check whether the bearing surface is unevenly worn or not. This wear and tear can cause the hoop side to rise and the coupling piece to come out of danger. When the load acts on the bearing surface, Load should be evenly distributed.

(5) Check the chucks on the chuck and elevator, and make sure they are released together. Otherwise, it is possible to dent or slip the tube.

-

Casing process in a factory

The alternative quenching method provided by this study can not only reduce the internal stress produced in the quenching process, but also guarantee the occurrence of martensitic transformation inside and outside the casing, which is beneficial to restrain the occurrence of quenching or to expand the crack.

-

Mg-Al spinel in the liquid steel of casing pipe begins to change into the liquid calcium aluminate; the magnesia-alumina spinel is more easily modified into the liquid inclusion than the alumina; the inclusions in the molten steel refining process are affected by the slag reaction and the influence of calcium treatment on the evolution of inclusions in the liquid state according to the Al2O3 → MgO-Al2O3 system inclusions → Ca O-Al2O3-MgO or Ca O-Al2O3 systems.

-

he stress and deformation of the ERW pipe will produce stress and deformation on the surface of the ERW pipe as long as it is welded in the production process of the ERW pipe, but the degree is different. The welding stress and deformation caused by the welding process of ERW welded pipe often reduce the quality of welded products and even cause cracks. The change of weld size and shape caused by welding deformation may not be connected with other pipes or the allowance of machining allowance can not be cut off. Below we say the pressure and the deformation.

-

Dimensional tolerance of erw steel pipe

-

The effect of roller adjustment on the quality of ERW has a process called roller adjustment when producing ERW pipes. During the production process, the roller is damaged or worn seriously. It is necessary to replace the unit on the part of the roller, or to produce a certain number of rollers continuously to meet the needs of the replacement of the whole roller. At this point, the roller should be adjusted to achieve excellent steel quality. If the roll adjustment is not good, it is easy to form the change of steel pipe seam, lap welding, edge wave, indentation or scratch on the surface of drum and pipe body, elliptical steel pipe and so on. Therefore, the roll adjustment prompt should be mastered when the roll is replaced.

-

1, choose the right process

From the comparison of several large longitudinal welded pipe technology and the development analysis of large longitudinal welded pipe technology in the world, UOE is the main DSAW tube unit in the world to produce high strength pipeline steel pipe. Its production capacity is large and the quality of the product is good. The developed countries in the world have established such a unit. China is a big iron and steel country. It is also a country with a large number of oil and gas pipelines. It is very necessary to build 1 or 2 advanced UOE devices in the world to produce high quality steel pipes for oil and gas pipelines. In addition, 2 to 3 sets of other double tube units can be constructed, such as C pressure molding and continuous forming (CFE). Although the output of these welded pipe units is low, they have less investment, quick construction and good flexibility. Good quality and strong ability to adapt to the market. In order to adapt to the development of the pipeline industry in China, the pipeline will gradually be DSAW tube, and the spiral welded pipe market is gradually transformed into the straight welded pipe market. This indicates that the construction of large longitudinal welded pipe will have a good prospect.