-

It is expected that the mainstream trend today will still show a downward adjustment in the construction of the plate. Although the iron ore price is currently running weakly, the attention of the public is still very high, and how it will be interpreted in the future.

-

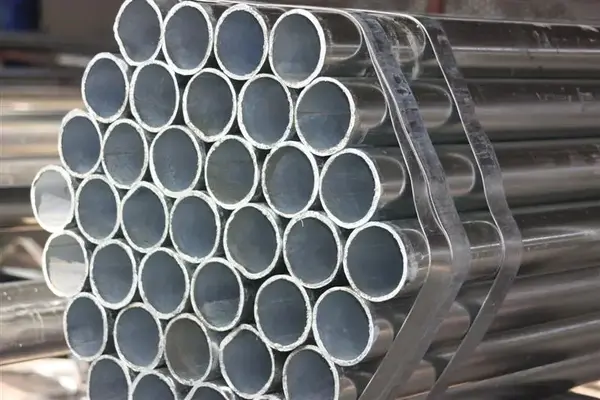

At present, there are fewer cold-rolled resources on the market. Although there are a small amount of resources to supplement the market one after another, overall, the resources available for circulation in the market are still limited.

-

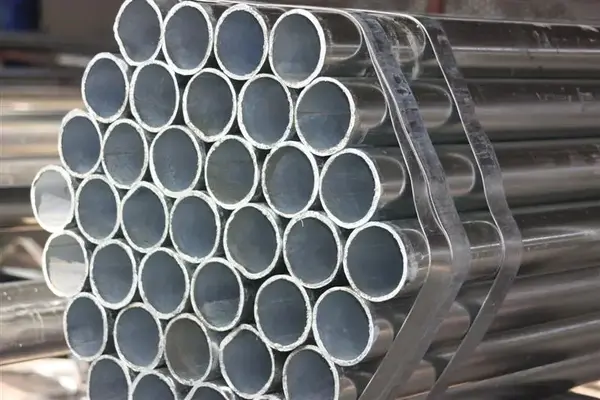

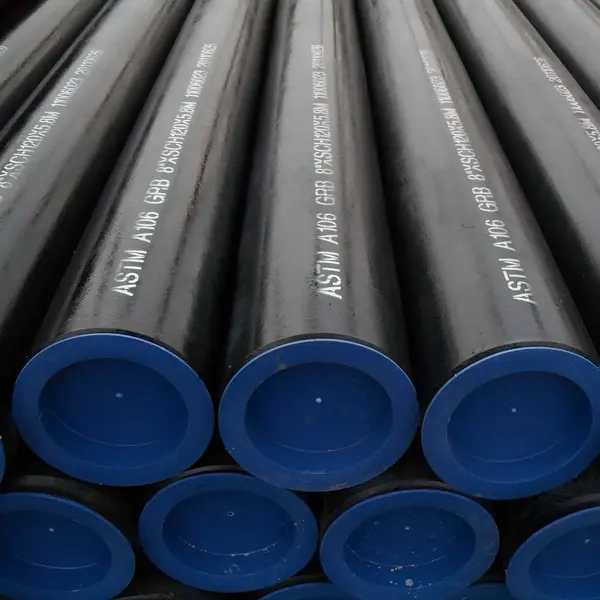

Perforation is the first process of deformation of hot-rolled seamless steel pipe, and its function is to pierce the solid tube blank into a hollow capillary tube. Since the surface defects or eccentricity (uneven wall thickness) of the pierced capillary tube are difficult to eliminate or reduce in the subsequent deformation process, the quality of the perforated capillary tube has an extremely important influence on the quality of the hot rolled seamless steel pipe. The tube blank perforation method includes pressure punching, push-rolling perforation and cross-rolling perforation.

-

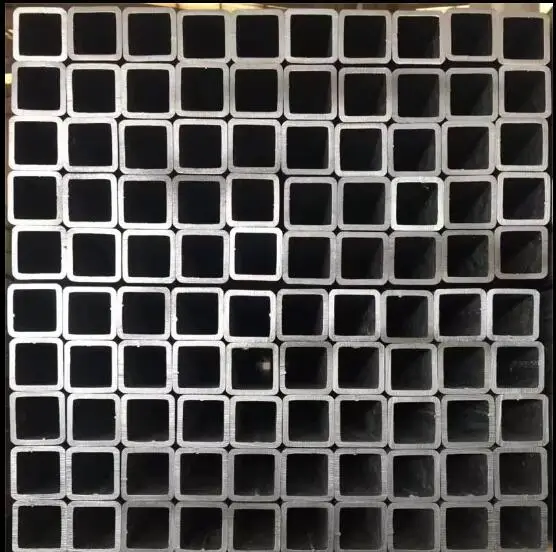

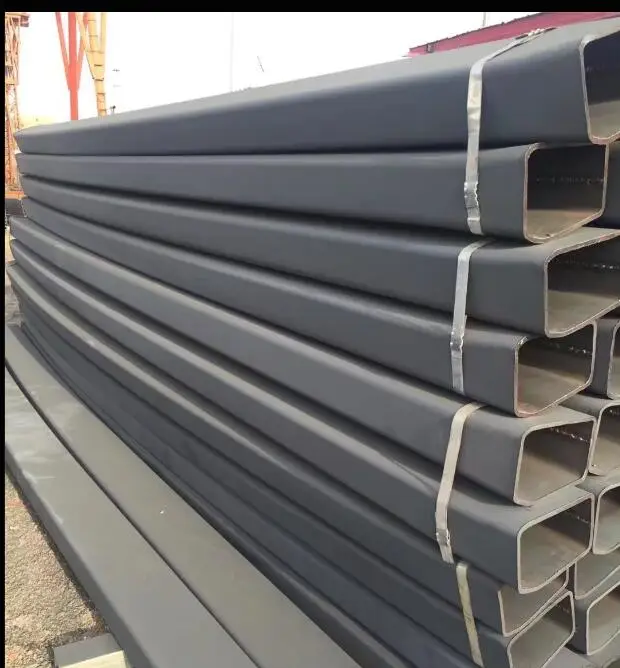

Steel structure refers to a structure mainly composed of steel materials and is one of the main types of building structures. The structure is mainly composed of steel beams, steel columns, steel trusses and other components made of steel and steel plates, and the joints, bolts or rivets are usually connected between the components or components. Because of its light weight and simple construction, it is widely used in large factories, stadiums, super high-rises and other fields.

-

The steel market continued its rebound last week. In addition to the weak and weak market, other major varieties of construction steel continued to rise. As the traditional terminal replenishment demand started before the Ching Ming Festival, the steel market transaction improved. However, in the second half of the week, after the steel price continued to rise and the demand for short-term replenishment of the terminal weakened, the situation of steady price decline also appeared. After a narrow period of consolidation in the previous period, the confidence of the domestic market has been adjusted.

-

Q345 channel steel price market traditional sales season, and because of the "golden nine" market failure, the market will habitually think that the delay of the peak season, may eventually fall to October, so before the National Day, the market for " The Silver Ten” peak season still has high expectations, and after the steel price has been consolidated for more than a month, there are conditions for a rebound. However, from the latest data released during the National Day, although the Chinese manufacturing PMI rebounded to 51.1% in September for three consecutive months, the final value of HSBC China's manufacturing PMI was only 50.2%, far less than expected and initial value. In addition, the PMI index of the steel industry for the month was only 49.2%, which fell sharply by 4.2 percentage points from the previous month and fell back below the dry line.

-

High-quality resources are tight and the price is high. Some mines have increased mine use, mine sales are better, traders are more active, and small and medium-sized mines are starting to improve slightly. However, most mines are still not satisfied with the current sales price. Under the premise of not having too much financing cost, the enthusiasm for returning to work is not high. Imported mines have recently been weak, and the mines have no suitable price hikes for the time being. Therefore, it is expected that the price of Shandong domestically produced ore will be stable this week.

-

The laser cutting process of petroleum screens has obvious advantages and can be used in the cutting process of many products. Hebei Rui Nair Petroleum Pipeline Equipment Co., Ltd. is a professional oil screen pipe manufacturer with advanced laser cutting machine. The quality of the oil screen produced is better and has been well received in the market.

-

The main dip dyeing of the drilling screen is to prevent sand. Because of the geology where the oil is mined, the steel grade and type of the unsuitable sand layer are not different. Drilling screens are cut into a number of longitudinal or spiral or cross-shaped cracks of a certain size in a variety of ways on oil casings or oil pipes.

-

Although the J55 oil casing market has an obvious upward trend, domestic injection coal prices are still quoted lower. It is reported that the average inventory and available days of coal injection in the national sample steel mills showed a slight increase. Some local small mines have gradually resumed production, but the current situation is not universal. Steel mills do not express their views on the rising purchase price.

-

A specially designed slotted screen trapezoidal wire winding is welded on a set of support wires arranged in a circumferential arrangement. Full-program welding ensures a strict continuous integrity of the product, resulting in a shape 2. The trapezoidal wire continuous winding forms a continuous high-density uniform gap on the circumferentially arranged support wires, ensuring the open area of the screen and non-blocking It avoids the high-density accumulation of sediments and provides a guarantee for increasing production efficiency and extending the service life of wells.

-

The domestic API5CT oil casings have been operating slightly, the steel mills' prices have increased slightly, the market transactions have improved, and the manufacturers' confidence has increased; the steel pipe market price has been slightly chaotic; the domestic molybdenum market has been generally sold, and the prices have fluctuated and consolidated; the domestic vanadium market The overall performance was slightly weaker, and the overall price showed a slight loosening;

-

Great wisdom ASDOCKS news agency on June 19, Malaysia's Ministry of International Trade and Industry announced on Wednesday, anti-dumping investigations on hot-rolled coils, plaid coils and pickled oil-coated coils from China, Indonesia and South Korea.

-

The HIsmelt process is the first commercial realization of the HIsmelt process. It is also the only new ironmaking process that can be used without coke and iron ore fines. Compared with the current blast furnace ironmaking process, it has ultra-low emission. The advantages of environmental protection and low investment cost, and the use of low-quality iron and carbon-containing raw materials to produce high-quality clean molten iron, this process provides a new idea for the transformation and upgrading of the steel industry.

-

The thermal conductivity of polyurethane is: λ=0.013—0.03kcal/m·h·oC, which is much lower than other commonly used pipe insulation materials, and the thermal insulation effect is improved by 4~9 times. Further, its water absorption rate is very low, about 0.2 kg/m2. The reason for the low water absorption rate is that the closed cell ratio of the polyurethane foam is as high as about 92%. The low thermal conductivity and low water absorption, plus the high-density polyethylene or FRP protective shell with good insulation and outer waterproofing, change the condition of the traditional ditch laying heating pipe “wet cotton quilting”, greatly reducing the heating pipe. The overall heat loss, heat network heat loss is 2%, far less than the international standard of 10%. 2, low heat loss, energy conservation According to the calculation of the relevant departments, under normal circumstances, polyurethane insulation steel pipe can reduce the project cost of 25% (using FRP as a protective layer) and 10% (using high-density polyethylene as a protective layer). 1. Reducing the advantages of engineering cost polyurethane insulation pipe:

-

Straight pipe joints Basics pressure pipe

straight seam steel pressure conduit basic concept

-

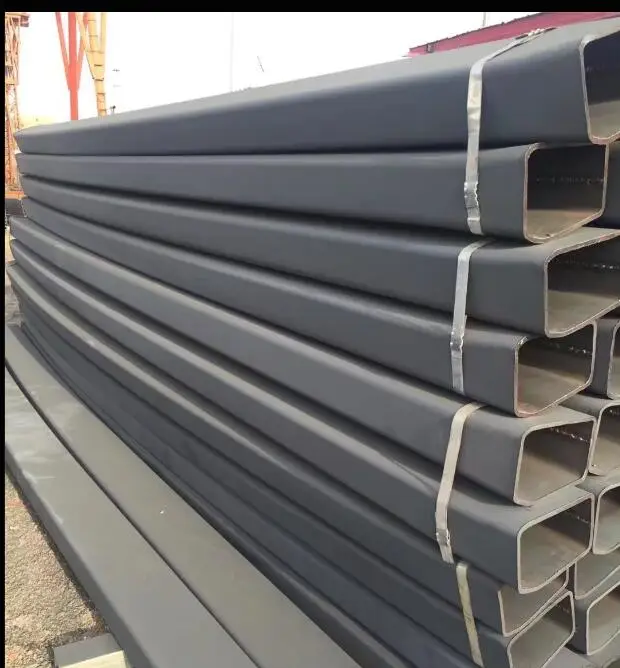

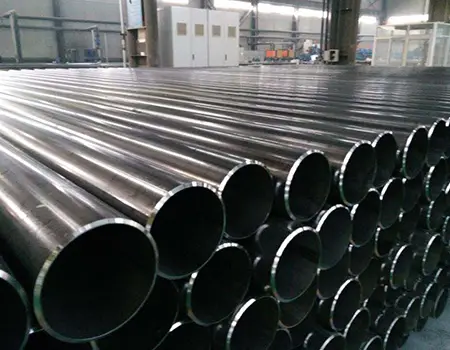

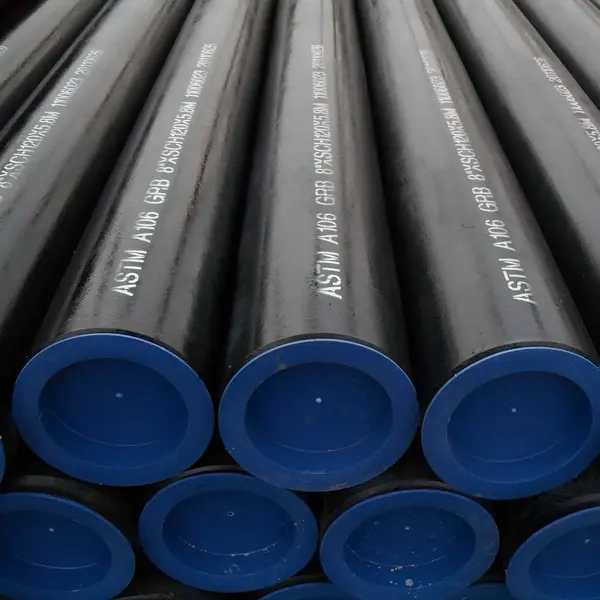

Straight seam steel pipes in industrial production often have two options, one is the use of ordinary straight seam steel pipe, and the other is a straight seam steel pipe with more and better performance. In the process of long-term production practice, companies have generally formed a consensus that this straight seam steel pipe with more good characteristics is superior to ordinary straight seam steel pipe in many aspects. This straight seam steel pipe is slightly better than the ordinary straight seam steel pipe, mainly because the straight seam steel pipe has several characteristics that ordinary straight seam steel pipe does not have.

-

Straight seam steel pipe production process. According to the production process, straight seam steel pipes can be divided into high-frequency straight seam steel pipes and submerged arc welded straight seam steel pipes. Submerged arc welded straight seam steel pipes are further divided into UOE, RBE, JCOE steel pipes according to their different molding methods. The following describes the most common molding processes for high-frequency straight seam steel tubes and submerged arc welded straight seam steel tubes.

-

Straight seam steel pipe is fully analyzed. The application of submerged arc welded straight seam steel pipe in the industry is obvious to all. Its wide application must be due to its unique advantages. However, as a successful business, we should fully understand this product, and analyze the advantages and disadvantages of hot-rolled steel pipe.

-

Straight seam steel pipe standard: (GB/T3091-2008) This standard includes straight seam steel pipe high frequency resistance welding (ERW straight seam steel pipe),

-

First clean the oil, paint, water, rust, etc. of the weld, and then open the groove according to the wall thickness, the thicker will open larger, the thin will open smaller (angle grinder) Then there is the gap of the product, usually 1-1.5 times the diameter of the electrode or wire. If you accidentally open the groove, you can leave it smaller. Point welding is at least three points, generally four points are better. When welding, it should be welded in half and half, and the starting point should be better than about one centimeter of the bottom point, so that the joint is good from the opposite side. If the wall thickness is thick, it should be layered, at least two layers, and the second layer can be welded after the first layer is completely welded.