-

The material should be chosen by the coating machine itself, because according to the installation and coating procedures, various materials can be used to meet the minimum requirements for the finished coating specified in this standard. Buyer should agree to any deviation from material use. The surface should be cleaned by sand blasting. Jet cleaning and any neces

-

Scope between ASTM A53 and ASTM A106

ASTM A53 is Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless.

ASTM A106 is Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service.

Application between ASTM A53 and ASTM A106

-

1, The supply of astm a53 seamless steel pipe compared to other traditional pipe, raw materials lighter, high strength, good tolerance, can withstand high internal pressure, the production of sensitive, and can be used to messy or harsh geological conditions.

-

As the individual quality of spiral steel pipe is relatively large, it must be stacked in the outdoors, but it will be difficult to avoid the sun and rain, so the problem has been plagued with rust spiral pipe storage time and conditions. Therefore, we need to conduct a comprehensive understanding of the spiral steel pipe rust prevention.

-

The thermal expansion seamless pipe is a thermal expansion pipe that we often say. Its density is relatively low, but the pipe has very high shrinkage. (Seamless steel pipe) can be called a thermal expansion pipe. A method for expanding the diameter of a pipe by a transverse rolling method or a drawing method; in a short time, the outside diameter of the steel pipe can produce a non-standard and special type of seamless pipe, and the cost is low and the production efficiency is high. It is an international roll pipe field. The development trend.

-

1, the next thick-walled seamless steel pipe easy to fold. Folding is the formation of a variety of fold lines on the surface of thick-walled seamless steel tubes, which often run through the entire product. The reason for the folding is that due to the pursuit of high-efficiency counterfeit manufacturers, the pressure is too great, the ear is caused, and the next rolling produces wrinkles, the folded product will be broken and bent, and the strength of the thick-walled seamless steel pipe will decrease.

-

The Costa Rican media "extro" reported in March 25th that if the economic and Commercial Ministry of Commerce (MEIC) approved the increase of steel import tax, the country will face a series of serious consequences. According to CCC's news, last week, the Ministry of economy and Commerce released an open investigation and resolution plan to take protective measures and raise the tariff of steel bars. As steel is the basic material for all kinds of production activities, especially in the construction industry, the association of architects, architectural and engineering consultants and the real estate development commission are firmly opposed to raising tariffs, which will exacerbate the current competitive conditions and may even return to the state of monopoly. Besides, the domestic people will be severely affected by the rising housing costs, which limits the basic rights of families to have decent housing. If the tax is estimated by the Ministry of Commerce and industry and commerce, it may reproduce the plight of steel shortage and high price.

-

In March 19, 2018, the Ministry of economic, industrial and foreign trade of Costa Rica issued a bulletin on the Official Bulletin No. fifty-first of 2018, and decided to apply for the application of Ansai romittal Costa Rica company to launch a survey on the safeguard measures for universal carbon and alloy steel bars. According to the bulletin clause, the investigation will be opened after the 10 natural days of the announcement. The Costa Rica import tax rate for products involved is 721420000010, 7214200000090, 721499200010722830000010722850000010 and 722860000010.

The interested parties are invited to register their complaints within 8 working days after the announcement and submit their answers in accordance with the requirements of the investigation organs within 45 natural days, and the answers may be postponed.

-

According to the report of the South African Daily News website on March 23, the Department of Trade and Industry of South Africa has formally submitted an application for seeking exemption from steel and aluminum duties to the United States. The ambassador of South Africa to the United States also recently traded to the National Security Council,

-

A few days ago, the Korea iron and Steel Association said that in February, the stock of cold rolled steel plates in South Korea reached 97 thousand and 400 tons, a decrease of 3.5% compared with the same period, an increase of 25.1% over the same period last year.

Generally speaking, the beginning of spring production will lead to the decline of stainless steel stock, but the sales of stainless steel in South Korea will keep warm. The stainless steel production in Korea is expected to be 90 thousand tons ~10 million tons. Therefore, the growth of stainless steel consumption in Korea is basically stagnant. South Korea's stainless steel cold-rolled plate producers and distributors are puzzled.

-

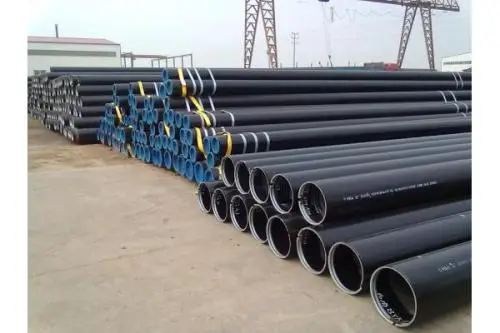

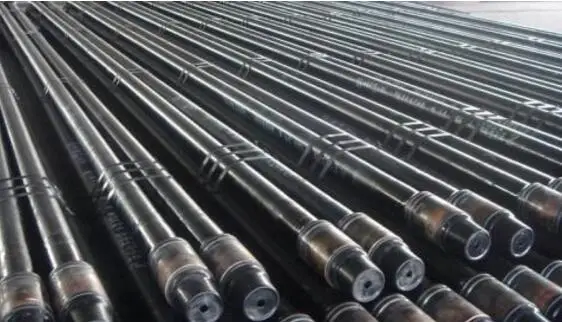

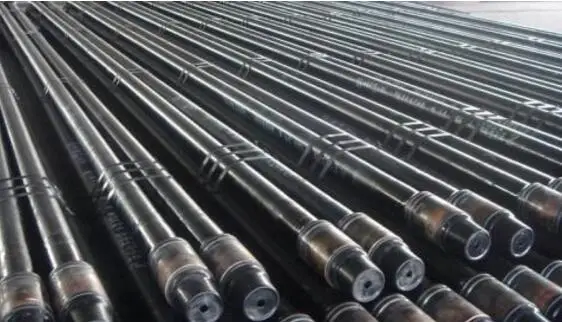

API 5L seamless steel pipe is characterized by its large diameter and relatively thick wall thickness. Therefore, according to this feature, full use of ultrasonic eddy current detection and internal and secondary surface detection functions are combined to achieve a “no blind spot” test. By adopting the “steel tube rotation and detection probe forward combination”, it not only solves the problem of detection of the title, but also solves the space that occupies a narrow space.

-

Description of API 5L Seamless Steel Pipe Equipment

Oil standard: Hydraulic pressure tester prevents oil corrosion after passing through the steel pipe, and marks according to user's requirements.

-

The use of spiral steel pipe is relatively high, and the application range is very wide. It should be selected before selection and pay attention to quality.

The first method is a more professional method of detection by measuring the strength of the pressure vessel. Normally, we use atmospheric pressure and water pressure detection, which can detect the working conditions of spiral steel tubes working under pressure and detect the tightness of spiral steel tubes. Generally, it is measured at atmospheric pressure because the safety is relatively high, if water is used. Vapor pressure passes the test and then the need for a spiral tube under water is too much trouble.

The second method is also relatively simple, that is, through the observation surface. Visually find problems with welding and size of spiral steel tubes, and if necessary, compare standard samples with products to find out where the problem lies. In general, the regular steel pipe company is relatively perfect in production, and on the other hand it is necessary to strike the metal pipe. If the sound is very crisp and the echo is not very dirty, then the name is the latest choice of steel pipe, not scrap recycling.

Both methods are commonly used. We can choose one method to test. The safer method is the best regular manufacturer, which can reduce the abuse during use.

-

The spiral steel strip is formed by spiral bending of a steel strip or a spiral plate and is welded on both sides by submerged arc welding. Steel pipes are widely used in water, electricity, chemical industry and other industries for the following reasons.

-

In March 26th, the latest data from the World Steel Association showed that India has become the world's second largest producer of coarse steel, with 8 million 430 thousand tons of crude steel in February 2018 and 8 million 300 thousand tons in Japan.

In the first 2 months of 2018, the crude steel output in India was 17 million 462 thousand tons, up 2.9% compared to the same period last year, and the crude steel output in Japan was 17 million 321 thousand tons, down 0.1% compared with the same period last year.

-

In March 23rd, the American steel Society (AISI) report showed that the United States imported 2 million 363 thousand short tons of crude steel in February this year, including 1 million 923 thousand short tons of finished products (18% and 17.6% respectively). The import of crude steel and finished products in the United States were 5 million 245 thousand short tons and 4 million 257 thousand short tons respectively in the first 2 months of this year, down 5.3% and 3.5% respectively over the same period of last year.

According to the report, it is estimated that imports of finished products accounted for 24% of the US market share in February this year, and the US market share of imported products accounted for 25% in the first 2 months. The total imports of crude steel and finished products will be 31 million 500 thousand short tons and 25 million 500 thousand short tons in 2018, down 17.5% and 13.6%, respectively.

In February this year, the main export products of the US increased significantly, including steel structure profiles (growth of 60%) and wire rod (37%). In the first 2 months, the major products of US imports increased substantially from the same year to year, including hot rolled coils (33%), pipeline (30%) and hot rolled steel (up 27%).

-

1. Look from the spiral steel pipe. Appearance should pay attention to those welded joints, to see the appearance is not a drawback, the lack of scale, you can see through the naked eye, of course, detailed and bilateral theory, borrow the standard model, gauges and magnifying glass to view. Due to the occurrence of welding defects, this means that the spiral pipe interior is most likely to have defects. Even if the surface efforts are not yet completed, internal efforts are difficult to guarantee.

-

Spiral steel pipe manufacturing loss rate refers to the spiral pipe in the manufacturing process, raw materials, waste ratio, according to professional and technical personnel for many years of statistical analysis spiral pipe manufacturing loss rate between 2% to 3%.

-

EFW (Electrofusion Welding) steel tube refers to electron beam welding. For directional impact kinetic energy electron beam, high-speed motion is used to transform the workpiece into a hot workpiece to leave the workpiece to melt and form a weld seam. EFW steel pipes are formed with hot rolled plates and welded welds. The welding flash can be removed from the outside or inside using the enmeshed blade surface. The weld zone can also be heat treated to make the weld invisible. Welded pipes generally have tighter dimensional tolerances than seamless pipes, and if manufactured in the same quantity, the cost is lower. It is mainly used for dissimilar steel welding thin plates or welding with high power density. The metal welding parts can be rapidly heated to high temperature and melt any refractory metals and alloys. The deep penetration welding speed and the heat affected zone are very small, so the impact on the joint performance is small, and the joint is hardly deformed. But it has special welding room requirements because of the use of X-ray welding.

-

Water pipes AWWA C200 steel pipes are widely used in the following fields/industries:

Hydroelectric power station, potable

Water supply industry, irrigation pressure pipeline, sewage treatment pipeline

-

ASTM A520 is a standard specification for the construction of high-temperature boilers for seamless and resistance-welded carbon steel pipe products in compliance with ISO recommended supplementary requirements.